Introduction: Navigating the Global Market for 3d sculpture

In today’s dynamic marketplace, navigating the global market for 3D sculpture presents unique challenges for B2B buyers. With a growing demand for customized designs and high-quality materials, sourcing the right sculptures can be daunting, particularly for businesses in Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Vietnam. This guide aims to demystify the intricate landscape of 3D sculpture by exploring various types, applications, and the latest trends in this artistic domain.

Understanding the diverse applications of 3D sculptures—from decorative art pieces to functional designs—enables businesses to make informed decisions tailored to their specific needs. We will delve into critical aspects such as supplier vetting processes, cost considerations, and innovative technologies shaping the industry. By equipping international buyers with actionable insights, this comprehensive guide empowers you to confidently select the right sculptures that align with your brand identity and market demands.

Whether you are looking to enhance your product offerings or create unique marketing displays, this resource will serve as your essential roadmap in the 3D sculpture market. As you embark on this journey, you will gain the knowledge necessary to foster successful partnerships and drive growth in your business.

สารบัญ

- Top 5 3D Sculpture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 3d sculpture

- Understanding 3d sculpture Types and Variations

- Key Industrial Applications of 3d sculpture

- 3 Common User Pain Points for ‘3d sculpture’ & Their Solutions

- Strategic Material Selection Guide for 3d sculpture

- In-depth Look: Manufacturing Processes and Quality Assurance for 3d sculpture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d sculpture’

- Comprehensive Cost and Pricing Analysis for 3d sculpture Sourcing

- Alternatives Analysis: Comparing 3d sculpture With Other Solutions

- Essential Technical Properties and Trade Terminology for 3d sculpture

- Navigating Market Dynamics and Sourcing Trends in the 3d sculpture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 3d sculpture

- Strategic Sourcing Conclusion and Outlook for 3d sculpture

- คำแถลงการณ์สำคัญและเงื่อนไขการใช้งาน

Understanding 3d sculpture Types and Variations

| ประเภท ชื่อ | คุณลักษณะเด่นที่แตกต่าง | การใช้งาน B2B หลัก | ข้อดีและข้อเสียโดยย่อสำหรับผู้ซื้อ |

|---|---|---|---|

| ประติมากรรมแบบดั้งเดิม | Handcrafted from materials like stone, wood, or metal. | Art galleries, interior design, public art. | ข้อดี: Unique, one-of-a-kind pieces. ข้อเสีย: High cost and longer lead times. |

| 3D Printed Sculpture | Created using additive manufacturing technology. | Prototyping, customized art, and decor. | ข้อดี: Cost-effective for small runs, rapid production. ข้อเสีย: Limited material options. |

| ประติมากรรมจลน์ | Incorporates movement through mechanical or natural forces. | Museums, exhibitions, and interactive displays. | ข้อดี: มีส่วนร่วมและมีชีวิตชีวา ข้อเสีย: Complex mechanics can increase costs. |

| Digital Sculpture | Created and visualized using 3D modeling software. | Digital art markets, virtual reality, and animation. | ข้อดี: Easily modifiable and scalable. ข้อเสีย: Requires technical expertise to produce. |

| ประติมากรรมนูนสูง | Sculptural forms that project from a flat background. | Wall decor, architectural elements. | ข้อดี: Space-efficient and versatile. ข้อเสีย: Limited depth may reduce visual impact. |

ลักษณะสำคัญของประติมากรรมแบบดั้งเดิมคืออะไร?

Traditional sculpture is defined by its handcrafted nature, utilizing materials such as stone, wood, or metal. This type is often sought after for its artistic value and the craftsmanship involved in its creation. Buyers in sectors like art galleries or interior design appreciate the unique, one-of-a-kind pieces that can serve as focal points in various settings. However, the higher costs and extended lead times associated with commissioning traditional sculptures can be significant considerations for B2B buyers.

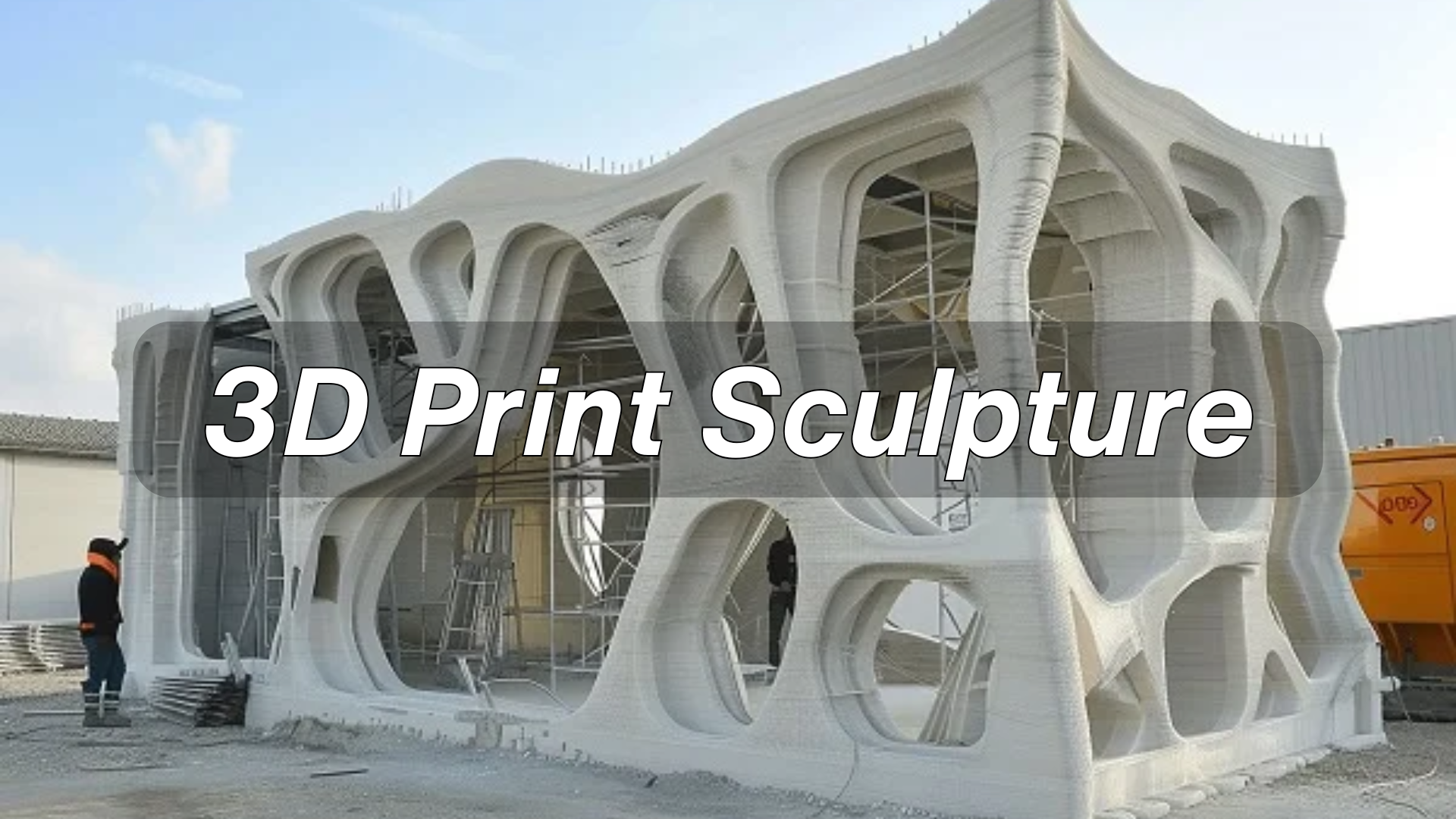

How Does 3D Printed Sculpture Benefit Businesses?

3D printed sculptures leverage additive manufacturing technology, allowing for rapid production and customization. This type of sculpture is increasingly popular in prototyping and decorative applications, making it ideal for businesses looking to create tailored art pieces or promotional items. The cost-effectiveness for small production runs is a significant advantage. However, buyers should be aware of the limited material options and potential durability concerns compared to traditional methods.

What Is Unique About Kinetic Sculpture?

Kinetic sculpture is characterized by its incorporation of movement, whether through mechanical means or natural forces like wind. This type of sculpture is particularly engaging and is often used in museums, exhibitions, and public spaces to create interactive experiences. While the dynamic nature of kinetic sculptures can captivate audiences, the complexity of their mechanics can lead to increased costs and maintenance requirements, which are crucial considerations for B2B buyers.

Why Choose Digital Sculpture for Your Business?

Digital sculpture involves creating and visualizing 3D models using software, which can then be rendered for various applications, including digital art markets and virtual reality. This type of sculpture offers the advantage of being easily modifiable and scalable, appealing to businesses that require flexibility in design. However, the need for technical expertise to produce digital sculptures can be a barrier for some buyers, necessitating partnerships with skilled digital artists or designers.

What Makes Relief Sculpture a Versatile Option?

Relief sculpture is distinguished by its design, which projects from a flat background, making it ideal for wall decor and architectural applications. This type is space-efficient and versatile, allowing for creative integration into various environments. While relief sculptures can enhance visual interest without occupying much space, their limited depth may reduce the overall impact compared to more dimensional forms, a factor that buyers should consider when making purchasing decisions.

Illustrative image related to 3d sculpture

Key Industrial Applications of 3d sculpture

| อุตสาหกรรม/ภาคส่วน | Specific Application of 3D Sculpture | คุณค่า/ประโยชน์ต่อธุรกิจ | ข้อพิจารณาสำคัญในการจัดหาสำหรับแอปพลิเคชันนี้ |

|---|---|---|---|

| Art & Design | Custom Artwork and Installations | Unique, tailored pieces that enhance brand identity | Quality of materials, design capabilities, and timelines |

| Cultural Heritage | Restoration of Historical Artifacts | Preserves cultural significance and attracts tourism | Expertise in restoration techniques and material sourcing |

| สถาปัตยกรรม | Sculptural Elements in Building Design | Enhances aesthetic appeal and structural uniqueness | Compliance with local regulations and environmental impact |

| การโฆษณาและการตลาด | Promotional Displays and Event Sculptures | Engages customers and creates memorable brand experiences | Customization options and production scalability |

| Education & Training | Educational Models for Schools and Institutions | Facilitates interactive learning and enhances engagement | Safety standards and durability of materials |

How is 3D Sculpture Revolutionizing the Art & Design Sector?

In the art and design industry, 3D sculpture is frequently utilized to create custom artwork and installations that resonate with target audiences. Businesses can leverage unique designs to strengthen their brand identity and differentiate themselves from competitors. Buyers should prioritize sourcing from suppliers who offer a variety of materials and design capabilities, ensuring the final product aligns with their vision and can be delivered within agreed timelines.

What Role Does 3D Sculpture Play in Cultural Heritage Restoration?

3D sculpture technology is instrumental in the restoration of historical artifacts, allowing for the accurate reproduction of damaged or lost pieces. This application not only preserves cultural significance but also contributes to the attraction of tourism, as restored sites can draw visitors eager to experience history. When sourcing, organizations must seek partners with expertise in restoration techniques and access to quality materials that match the original artifacts.

How Does 3D Sculpture Enhance Architectural Design?

In architecture, 3D sculpture is used to incorporate sculptural elements into building designs, adding aesthetic appeal and uniqueness to structures. This trend can elevate the overall design of a project, making it more visually striking and memorable. Buyers in this sector should consider compliance with local regulations regarding construction and environmental impact when sourcing these sculptural elements to ensure sustainable and legal practices.

Illustrative image related to 3d sculpture

Why is 3D Sculpture Important in Advertising & Marketing?

3D sculptures are increasingly being used for promotional displays and event sculptures that captivate customers and create lasting brand experiences. These engaging pieces can draw attention in crowded marketplaces, making them an effective tool for enhancing brand visibility. When sourcing, businesses should focus on customization options that allow for alignment with specific marketing campaigns and consider the scalability of production to meet demand.

How is 3D Sculpture Beneficial for Education & Training?

In educational settings, 3D sculptures serve as interactive models that facilitate learning and enhance engagement among students. These tangible representations can simplify complex concepts and make learning more enjoyable. Buyers should ensure that the materials used are safe and durable, suitable for the educational environment, and that suppliers can provide a range of models tailored to specific curricular needs.

3 Common User Pain Points for ‘3d sculpture’ & Their Solutions

Scenario 1: Sourcing Quality 3D Sculpture Models for Diverse Markets

ปัญหา: B2B buyers often struggle to find high-quality, culturally relevant 3D sculpture models that resonate with their specific target markets. For example, a buyer in Saudi Arabia may want to source sculptures that reflect local culture and art forms, yet they may find a limited selection that caters to their needs. This can lead to frustration and delays in project timelines, ultimately affecting their competitiveness in the market. Additionally, differences in design preferences across regions, such as minimalistic styles favored in Europe versus more ornate designs in South America, complicate sourcing further.

ทางแก้ไข: To effectively source quality 3D sculpture models, buyers should leverage specialized platforms that offer extensive libraries of 3D assets. Websites like Sketchfab or CGTrader provide a diverse range of models, including those tailored to specific cultural contexts. Additionally, buyers can collaborate with local artists or designers who understand the cultural nuances and can create bespoke pieces. Establishing relationships with 3D modeling firms in regions of interest can also be beneficial, as they can provide tailored solutions that align with local tastes. Buyers should consider setting up a clear specification document that outlines their requirements, including style, material, and intended use, which will streamline communication and ensure that the final product meets their expectations.

Illustrative image related to 3d sculpture

Scenario 2: Managing Production and Material Costs

ปัญหา: The cost of producing 3D sculptures can quickly escalate due to fluctuating material prices, especially for industries that rely on high-quality or specialized materials like resin or metal. B2B buyers may find themselves facing unexpected expenses that could derail budgets and timelines. For instance, a company planning to use 3D sculptures for an exhibition might discover last-minute price hikes in materials, forcing them to either compromise on quality or delay their project.

ทางแก้ไข: To mitigate these financial risks, buyers should adopt a proactive approach by establishing relationships with multiple suppliers to ensure competitive pricing and availability of materials. Conducting thorough market research to identify trends in material costs can also help buyers forecast expenses more accurately. Implementing a Just-In-Time (JIT) inventory system can reduce excess inventory costs while ensuring that materials are available when needed. Furthermore, buyers can explore 3D printing technologies that utilize cost-effective materials without sacrificing quality, such as biodegradable filaments or recycled plastics, which not only lower costs but also enhance sustainability efforts.

Scenario 3: Ensuring High-Quality Output in Diverse Production Environments

ปัญหา: Inconsistent quality in the final output of 3D sculptures can be a significant pain point for B2B buyers, particularly when outsourcing production to different manufacturers. Variations in technology, printing methods, or even the skill level of the operators can lead to discrepancies in the quality of the sculptures produced. A buyer in Europe, for example, may receive a batch of sculptures that do not meet their high aesthetic standards, impacting their brand reputation and customer satisfaction.

ทางแก้ไข: To ensure consistent quality, buyers should establish clear quality standards and guidelines that all manufacturers must adhere to. This includes specifications for dimensions, tolerances, material characteristics, and finishing techniques. Conducting thorough vetting of potential suppliers, including factory visits and sample evaluations, can help identify those capable of meeting these standards. Additionally, implementing a quality assurance process, such as regular inspections and feedback loops, allows buyers to maintain oversight and address any issues promptly. Investing in training programs for suppliers can also enhance their capabilities and ensure they are equipped to meet the buyer’s quality expectations consistently.

Illustrative image related to 3d sculpture

Strategic Material Selection Guide for 3d sculpture

When selecting materials for 3D sculpture, it is essential for B2B buyers to consider the properties, advantages, and limitations of various materials. This strategic approach ensures that the final product meets the desired aesthetic and functional requirements while adhering to regional standards and regulations.

What Are the Key Properties of PLA in 3D Sculpture?

Polylactic Acid (PLA) is a popular biodegradable thermoplastic derived from renewable resources like cornstarch or sugarcane. It boasts a low melting temperature, typically around 180-220°C, making it suitable for a variety of 3D printing applications. PLA is known for its excellent layer adhesion and fine detail reproduction, which is critical for intricate sculptures. However, it has limited heat resistance, with a glass transition temperature of about 60°C, which can affect its durability in high-temperature environments.

Pros and Cons of PLA for B2B Buyers

PLA is relatively inexpensive and widely available, making it an attractive option for large-scale production. Its biodegradable nature aligns with sustainability goals, appealing to environmentally conscious markets. However, its lower durability and heat resistance may limit its suitability for outdoor sculptures or pieces exposed to harsh conditions.

How Does ABS Compare as a Material for 3D Sculpture?

Acrylonitrile Butadiene Styrene (ABS) is another widely used thermoplastic known for its strength and impact resistance. With a melting temperature of approximately 220-250°C, ABS can withstand higher temperatures than PLA, making it suitable for more demanding applications. It also offers good chemical resistance, which is beneficial for sculptures intended for various environments.

Pros and Cons of ABS for B2B Buyers

ABS is durable and offers a good finish, making it ideal for detailed sculptures. However, it requires a heated bed during printing to minimize warping, which can complicate the manufacturing process. Additionally, ABS emits fumes during printing, necessitating proper ventilation, which may be a concern for buyers in regions with strict environmental regulations.

What Are the Benefits of Using Resin for 3D Sculpture?

Resin, particularly photopolymer resin used in SLA (Stereolithography) printing, provides exceptional detail and surface finish. The curing process involves UV light, allowing for intricate designs and smooth surfaces. Resins typically have a low viscosity, facilitating the creation of complex geometries that might be challenging with thermoplastics.

Pros and Cons of Resin for B2B Buyers

Resin is ideal for high-detail sculptures and prototypes, but it is generally more expensive than filament-based materials. The curing process can be time-consuming, and post-processing is often required to achieve the desired finish. Additionally, resins can be brittle, limiting their use in applications requiring flexibility or impact resistance.

Why Consider Metal for 3D Sculpture Applications?

Metal 3D printing, particularly using materials like stainless steel or aluminum, offers unmatched durability and aesthetic appeal. Metal sculptures can withstand extreme conditions and provide a premium finish that is often sought after in high-end markets. The melting temperatures for metal powders can exceed 1000°C, allowing for robust applications.

Pros and Cons of Metal for B2B Buyers

Metal sculptures are incredibly durable and suitable for outdoor installations. However, the cost of metal 3D printing is significantly higher than plastic or resin, making it less accessible for smaller projects. The manufacturing process is also more complex, requiring specialized equipment and expertise.

Summary Table of Material Selection for 3D Sculpture

| วัสดุ | Typical Use Case for 3D Sculpture | ข้อได้เปรียบหลัก | ข้อเสีย/ข้อจำกัดที่สำคัญ | ต้นทุนสัมพัทธ์ (ต่ำ/ปานกลาง/สูง) |

|---|---|---|---|---|

| PLA | Decorative indoor sculptures | Biodegradable and easy to print | Limited heat resistance | ต่ำ |

| เอเอบีเอส | Functional and durable sculptures | Strong and impact-resistant | Requires heated bed and ventilation | ระดับกลาง |

| เรซิน | High-detail prototypes and art pieces | Exceptional detail and finish | Brittle and requires post-processing | สูง |

| โลหะ | ประติมากรรมกลางแจ้งคุณภาพสูง ทนทาน | Unmatched durability and aesthetic | ต้นทุนสูงและการผลิตที่ซับซ้อน | สูง |

This material selection guide is designed to assist B2B buyers in making informed decisions based on their specific needs and regional market conditions. By understanding the properties and implications of each material, buyers can optimize their procurement strategies for 3D sculptures.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d sculpture

What Are the Main Stages in the Manufacturing Process of 3D Sculptures?

The manufacturing process of 3D sculptures typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is essential for B2B buyers to assess the quality and suitability of suppliers.

How is Material Prepared for 3D Sculpture Production?

Material preparation is the foundational step in the 3D sculpture manufacturing process. Common materials include various types of plastics, resins, metals, and ceramics. For instance, thermoplastics like PLA and ABS are frequently used for their ease of use and availability.

Illustrative image related to 3d sculpture

Before the actual printing or molding begins, these materials must be properly conditioned. This can include drying to remove moisture, grinding into fine particles for more consistent melting, or even mixing with additives to enhance properties such as strength or flexibility. For buyers, understanding the supplier’s material sourcing and preparation methods can be crucial for ensuring the final product meets specific performance criteria.

What Forming Techniques Are Commonly Used in 3D Sculpture Creation?

Forming techniques in 3D sculpture manufacturing primarily involve additive and subtractive methods. Additive manufacturing, or 3D printing, is the most common technique and includes processes like Fused Deposition Modeling (FDM) and Stereolithography (SLA).

FDM utilizes thermoplastic filaments that are heated and extruded layer by layer to build the sculpture. SLA, on the other hand, uses a liquid resin that is cured with UV light, allowing for highly detailed and intricate designs.

Subtractive manufacturing techniques, such as CNC machining, can also be employed to refine sculptures or create molds. For B2B buyers, knowing the techniques used can help in evaluating the capability of a supplier to produce the desired detail and finish.

How Are Sculptures Assembled and Finished in the Manufacturing Process?

The assembly stage may be required for larger or multi-part sculptures, where components created through different processes are joined together. Techniques include adhesives, mechanical fasteners, or even welding for metal parts.

Illustrative image related to 3d sculpture

Finishing processes are critical for the aesthetic and functional quality of the sculpture. This can involve sanding, painting, or applying protective coatings to enhance durability and appearance. Buyers should inquire about the finishing options available and the specific methods used, as these can greatly affect the final product’s quality.

What Quality Control Standards Should B2B Buyers Be Aware Of?

Quality assurance in 3D sculpture manufacturing is critical for maintaining product integrity and compliance with international standards. The ISO 9001 standard, which outlines requirements for a quality management system, is one of the most recognized benchmarks across various industries, including sculpture manufacturing.

How Do International Standards and Industry-Specific Certifications Impact Quality Assurance?

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the end use of the sculptures. For instance, sculptures intended for outdoor display may need to meet additional weather resistance standards.

Buyers should ensure that their suppliers are compliant with these standards as they signify a commitment to quality and safety. Furthermore, compliance can be crucial for market entry in certain regions, particularly in Europe and the Middle East, where regulations can be stringent.

What Are the Key Quality Control Checkpoints in the 3D Sculpture Manufacturing Process?

Quality control (QC) checkpoints are integral to ensuring that the sculptures meet the required specifications throughout the manufacturing process. The following are key QC checkpoints:

Illustrative image related to 3d sculpture

การควบคุมคุณภาพขาเข้า (IQC): This stage verifies the quality of raw materials before they enter the production line. Materials that do not meet specified standards are rejected.

การควบคุมคุณภาพระหว่างกระบวนการ (IPQC): During the manufacturing process, inspections are conducted at various stages to ensure that the production is on track and that any defects are identified early.

การควบคุมคุณภาพขั้นสุดท้าย (FQC): Once the sculptures are completed, a thorough inspection is conducted to assess the final product against quality standards. This may include dimensional checks, visual inspections, and functional testing if applicable.

ผู้ซื้อ B2B สามารถตรวจสอบการควบคุมคุณภาพของผู้จัดจำหน่ายได้อย่างไร?

Verifying a supplier’s quality control practices is essential for B2B buyers. Here are some actionable steps:

ดำเนินการตรวจสอบผู้จัดหา: Regular audits help assess the supplier’s adherence to quality standards and processes. This can include facility visits and reviewing QC documentation.

ขอรายงานการควบคุมคุณภาพ: Suppliers should provide detailed QC reports that outline their processes, test results, and compliance with international standards.

จ้างผู้ตรวจสอบจากบุคคลที่สาม: Utilizing independent inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is particularly useful when dealing with suppliers in different regions, such as Africa, South America, or the Middle East.

ผู้ซื้อระหว่างประเทศควรพิจารณาประเด็นคุณภาพ (QC) ที่ไม่เหมือนใครอะไรบ้าง?

International B2B buyers must navigate additional complexities in quality assurance due to differences in regulations, standards, and practices across regions. For instance:

Understanding Local Standards: Buyers should be aware of the specific standards applicable in their region, such as ASTM standards in the U.S. or EN standards in Europe, to ensure compliance.

Cultural and Language Barriers: Communication regarding quality expectations can be challenging due to cultural differences. Establishing clear guidelines and expectations upfront can mitigate these issues.

Logistics and Supply Chain Risks: International shipping can expose sculptures to damage. Buyers should discuss packaging and handling procedures with suppliers to ensure that products arrive in pristine condition.

In summary, understanding the manufacturing processes and quality assurance measures is vital for B2B buyers in the 3D sculpture market. By focusing on material preparation, forming techniques, assembly, finishing, and robust QC practices, buyers can make informed decisions that align with their quality expectations and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d sculpture’

In the fast-evolving world of 3D sculpture, sourcing the right products for your business requires a strategic approach. This guide provides a comprehensive checklist for B2B buyers, ensuring you make informed decisions while procuring 3D sculptures. By following these steps, you can enhance your sourcing process and ensure the quality and relevance of the sculptures you acquire.

Illustrative image related to 3d sculpture

ขั้นตอนที่ 1: กำหนดความต้องการของโครงการของคุณ

Clearly outline your project’s objectives, including the type of sculptures needed (e.g., decorative, functional, or artistic). Consider the intended use, target audience, and desired materials. This clarity will guide your search and help you communicate effectively with potential suppliers.

ขั้นตอนที่ 2: วิจัยและระบุซัพพลายเออร์

Conduct thorough research to identify potential suppliers specializing in 3D sculptures. Look for companies with a proven track record in your specific region, such as Africa, South America, or Europe. Utilize online platforms, trade shows, and industry forums to compile a list of reputable manufacturers and artists.

ขั้นตอนที่ 3: ประเมินศักยภาพของผู้จัดหา

Assess the technical capabilities of each supplier. Investigate their production methods, material options, and design flexibility. Ensure they can handle your specific requirements, whether you need large-scale sculptures or intricate designs. It’s essential to confirm that the supplier has the right technology, such as advanced 3D printers or sculpting tools.

Illustrative image related to 3d sculpture

ขั้นตอนที่ 4: ขอตัวอย่างและต้นแบบ

Before finalizing any orders, request samples or prototypes of their work. This step is crucial to evaluate the quality, craftsmanship, and adherence to your specifications. Pay attention to details like finish, durability, and overall aesthetics, as these factors can significantly impact your project’s success.

ขั้นตอนที่ 5: ตรวจสอบการรับรองและการปฏิบัติตามข้อกำหนดของผู้จัดจำหน่าย

Ensure that your chosen suppliers comply with international standards and certifications relevant to 3D printing and sculpture production. This includes environmental regulations, safety standards, and quality assurance certifications. Verification of these credentials can mitigate risks associated with sourcing from unreliable suppliers.

ขั้นตอนที่ 6: เข้าใจราคาและเงื่อนไขการชำระเงิน

Discuss pricing structures and payment terms with potential suppliers. It’s important to obtain a detailed quote that includes all costs, such as shipping and handling. Clarify payment methods and terms to avoid any misunderstandings later in the procurement process. Consider negotiating bulk order discounts if applicable.

ขั้นตอนที่ 7: จัดตั้งช่องทางการสื่อสารและการสนับสนุน

Maintain open lines of communication with your suppliers throughout the sourcing process. Establish clear points of contact and preferred communication methods to facilitate efficient collaboration. Good communication is vital for addressing any issues that may arise and ensuring your project stays on track.

By following this sourcing checklist, B2B buyers can navigate the complexities of procuring 3D sculptures more effectively. Each step is designed to enhance your decision-making process, ensuring that the sculptures you acquire meet your business needs and expectations.

Illustrative image related to 3d sculpture

Comprehensive Cost and Pricing Analysis for 3d sculpture Sourcing

What Are the Key Cost Components in 3D Sculpture Sourcing?

When sourcing 3D sculptures, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

วัสดุ: The choice of materials significantly impacts costs. Common options for 3D sculptures include plastics, resins, metals, and ceramics. Each material has a different price point, and factors such as availability and quality will influence costs. For instance, high-quality resins used in detailed sculptures may cost more than standard plastics.

แรงงาน: Labor costs encompass not only the wages paid to artisans but also the skilled labor required for design and production. The complexity of the sculpture can increase labor costs, especially for custom designs requiring specialized skills.

ค่าใช้จ่ายโรงงาน: This includes utilities, rent, and equipment maintenance associated with production facilities. Overhead can vary widely based on geographic location and the scale of production.

เครื่องมือ: Initial tooling costs can be substantial, especially for custom pieces requiring molds or specialized machinery. This upfront investment is often amortized over the production run, influencing the per-unit cost.

การควบคุมคุณภาพ (QC): Ensuring that sculptures meet quality standards incurs additional costs. This includes inspection processes and any rework needed for defective items. Investing in robust QC can prevent larger losses due to returns or damaged reputations.

ลอจิสติกส์: Transportation and shipping costs can vary based on the size and weight of the sculptures, as well as the distance they need to travel. International shipping may incur customs duties and tariffs, adding to overall expenses.

มาร์จิน: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can fluctuate based on competition and market demand.

How Do Price Influencers Affect the Cost of 3D Sculptures?

Several factors can influence the pricing of 3D sculptures, particularly in international B2B transactions:

ปริมาณ/MOQ (ปริมาณการสั่งซื้อขั้นต่ำ): Larger orders often lead to discounts. Suppliers may offer better pricing for bulk purchases, which can be a significant factor for businesses looking to stock inventory.

ข้อมูลจำเพาะและการปรับแต่ง: Custom designs or specific requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

วัสดุและการรับรองคุณภาพ: Higher-quality materials or those with specific certifications (e.g., eco-friendly) can raise costs. Buyers need to balance quality with budget constraints.

ปัจจัยของผู้จัดหา: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but provide assurance of quality and timely delivery.

Incoterms: Understanding international shipping terms (Incoterms) is critical. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect total costs, including risk and responsibility for damages during transport.

What Buyer Tips Can Enhance Cost-Efficiency in 3D Sculpture Sourcing?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negotiate Terms and Prices: Always seek to negotiate terms, especially on larger orders. Suppliers may be willing to adjust prices or offer better payment terms to secure a deal.

Consider Total Cost of Ownership (TCO): Beyond initial purchase prices, consider ongoing costs such as maintenance, shipping, and potential tariffs. A lower upfront cost may not always lead to the best value.

Understand Pricing Nuances: Different regions may have varying pricing strategies. For instance, buyers from Europe may face different tariffs than those from the Middle East. Understanding these nuances can aid in budgeting.

สร้างความสัมพันธ์กับผู้จัดหา: Establishing long-term relationships can lead to better pricing, priority service, and insights into new products or materials.

Research and Compare Suppliers: Utilize platforms like Printables, Sketchfab, and CGTrader to compare products, prices, and supplier reputations. Being well-informed can lead to more advantageous purchasing decisions.

สรุป

Understanding the cost and pricing structure of 3D sculpture sourcing is vital for international B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic purchasing tips, buyers can optimize their sourcing strategies and secure the best value for their investments.

Alternatives Analysis: Comparing 3d sculpture With Other Solutions

Introduction to Alternative Solutions for 3D Sculpture

In the realm of art and design, particularly in the B2B sector, the need for innovative and effective solutions is ever-growing. While 3D sculpture represents a cutting-edge approach to creating three-dimensional artworks or prototypes, several alternative methods and technologies are available. Understanding these alternatives can help businesses make informed decisions based on performance, cost, and application.

Illustrative image related to 3d sculpture

ตารางเปรียบเทียบ

| การเปรียบเทียบ | 3D Sculpture | การกลึงด้วยเครื่องจักร CNC | ประติมากรรมแบบดั้งเดิม |

|---|---|---|---|

| ประสิทธิภาพ | High detail and complexity | Precise, but limited to materials | Variable, dependent on artist skill |

| ค่าใช้จ่าย | ปานกลางถึงสูง | การลงทุนเริ่มต้นสูง | Variable, can be costly |

| ความสะดวกในการนำไปใช้ | Requires specialized equipment and software | Complex setup and programming | Labor-intensive, requires skilled artisans |

| การบำรุงรักษา | Low (once produced) | Moderate (tool upkeep) | High (artist involvement) |

| กรณีการใช้งานที่ดีที่สุด | Prototyping, custom art | Industrial applications, mass production | Unique, handcrafted pieces |

รายละเอียดการแยกแยะทางเลือก

การกลึงด้วยเครื่องจักร CNC

CNC (Computer Numerical Control) machining is a method that uses computer-controlled tools to create precise parts from various materials, including wood, metal, and plastic. This technology excels in performance, particularly in producing intricate designs with high accuracy. However, the initial setup cost can be significant, making it less accessible for smaller businesses. Moreover, the complexity of programming CNC machines can pose a challenge for those unfamiliar with the technology. CNC machining is best suited for industrial applications where precision and repeatability are paramount, such as automotive parts or intricate components.

ประติมากรรมแบบดั้งเดิม

Traditional sculpture involves the handcrafting of artworks using various materials like clay, stone, or metal. This method relies heavily on the skill and creativity of the artist, resulting in unique, one-of-a-kind pieces. While traditional sculpture can produce stunning works of art, the process is labor-intensive and time-consuming, which can drive up costs. Moreover, the variability in quality and style can be a drawback for businesses seeking consistency. This alternative shines in contexts where bespoke, artisanal products are valued, such as luxury decor or custom commissions.

สรุป: การเลือกโซลูชันที่เหมาะสมกับความต้องการของคุณ

When selecting between 3D sculpture and its alternatives, B2B buyers should consider their specific needs, including budget constraints, desired level of detail, and production requirements. For businesses looking to create intricate prototypes or custom art pieces, 3D sculpture offers a unique blend of flexibility and detail. Conversely, if precision in mass production is a priority, CNC machining may be the preferred choice. Lastly, for those who value craftsmanship and uniqueness, traditional sculpture remains an irreplaceable option. Evaluating these factors will enable businesses to make the best decision tailored to their operational goals and artistic vision.

Essential Technical Properties and Trade Terminology for 3d sculpture

What Are the Essential Technical Properties in 3D Sculpture?

In the realm of 3D sculpture, understanding the technical specifications is crucial for B2B buyers looking to invest in quality pieces. Below are several key properties that define the quality and usability of 3D sculptures.

1. วัสดุเกรด

The material grade refers to the quality and type of materials used in the sculpture, such as PLA, ABS, or resin for 3D printing. Each material has unique properties, such as durability, flexibility, and finish quality. B2B buyers must consider the intended use of the sculpture—whether for display, art, or functional purposes—when evaluating material grades, as this directly impacts longevity and performance.

2. Print Resolution

Print resolution is defined by the layer height in millimeters, which affects the detail and smoothness of the final sculpture. A lower layer height results in higher resolution and finer details, while a higher layer height can speed up production but may compromise quality. For businesses, choosing the right print resolution is essential for meeting client expectations and ensuring the final product aligns with their vision.

Illustrative image related to 3d sculpture

3. ระดับความทนทาน

Tolerance levels indicate the allowable deviation from specified dimensions in the sculpture. In the context of 3D printing, tighter tolerances lead to more accurate and fitting components, which is critical for intricate designs or parts that must fit together. For B2B buyers, understanding tolerance levels ensures that the final product meets functional requirements, especially in applications like prototypes or custom installations.

4. Weight and Density

The weight and density of a sculpture impact its transportability and stability. Different materials will yield different weights, which is vital for shipping and installation considerations. Buyers must evaluate the sculpture’s weight to ensure it meets their logistical needs and fits within their intended display environment.

5. พื้นผิว

Surface finish refers to the texture and aesthetic quality of the sculpture’s exterior. Options may include matte, glossy, or textured finishes, each providing a different visual appeal. For B2B buyers, the choice of surface finish can enhance the sculpture’s marketability and consumer appeal, making it crucial to select a finish that aligns with branding and target audience preferences.

Illustrative image related to 3d sculpture

What Common Terms Should You Know in the 3D Sculpture Trade?

Navigating the world of 3D sculpture also requires familiarity with specific industry jargon. Here are some common terms that B2B buyers should understand.

1. OEM (ผู้ผลิตอุปกรณ์ดั้งเดิม)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the 3D sculpture industry, an OEM might create sculptures for a brand that sells them under its name. Understanding OEM relationships can help buyers identify quality assurance and brand reputation.

2. MOQ (ปริมาณการสั่งซื้อขั้นต่ำ)

MOQ is the smallest amount of product a supplier is willing to sell. In the 3D sculpture market, knowing the MOQ is essential for buyers to plan their budgets and inventory levels effectively. It can also indicate the supplier’s production capabilities and market demand.

Illustrative image related to 3d sculpture

3. RFQ (คำขอเสนอราคา)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. B2B buyers use RFQs to compare costs and negotiate terms before making purchasing decisions. This practice helps ensure that businesses are getting the best value for their investment.

4. อินโคเทิร์ม (เงื่อนไขการค้าสากล)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms is crucial for B2B buyers, as it determines who bears costs and risks during transportation, thereby influencing overall pricing strategies.

5. CAD (Computer-Aided Design)

CAD refers to the use of software to create precision drawings or technical illustrations. In 3D sculpture, CAD files are often the starting point for production. For buyers, understanding CAD can facilitate better communication with designers and manufacturers, ensuring that the final product meets their specifications.

Illustrative image related to 3d sculpture

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing 3D sculptures, leading to successful partnerships and projects.

Navigating Market Dynamics and Sourcing Trends in the 3d sculpture Sector

What Are the Current Market Dynamics and Key Trends in the 3D Sculpture Sector?

The 3D sculpture sector is witnessing a transformative wave driven by technological advancements, shifting consumer preferences, and global market dynamics. A key driver is the increasing adoption of 3D printing technologies, which allow for rapid prototyping and customization of sculptures. This trend is particularly significant for international B2B buyers, as it enables companies to offer unique products tailored to regional tastes and cultural preferences. For instance, sculptures that resonate with local heritage can be produced efficiently, appealing to markets in Africa, South America, and the Middle East.

Emerging technologies, such as AI-driven design tools, are also reshaping the sourcing landscape. Platforms like MakerLab and Sketchfab allow businesses to create and modify 3D models easily, reducing the need for extensive technical skills. This democratization of design fosters innovation and can lead to a wider variety of offerings. Additionally, the global market is seeing a rise in demand for interactive and experiential sculptures, particularly in urban settings and cultural events, which require buyers to stay attuned to trends that blend art with technology.

Moreover, the impact of e-commerce on the 3D sculpture market cannot be overstated. International buyers are increasingly utilizing online platforms for sourcing, allowing for broader access to suppliers and manufacturers worldwide. This shift not only streamlines procurement processes but also enhances competition, driving down costs and improving quality. As B2B buyers navigate this dynamic landscape, staying informed about these trends is crucial for maintaining a competitive edge.

How Does Sustainability and Ethical Sourcing Impact B2B in the 3D Sculpture Sector?

Sustainability is becoming a cornerstone of business practices within the 3D sculpture sector, particularly as global awareness of environmental issues grows. For B2B buyers, understanding the environmental impact of materials and production methods is essential. Traditional sculpting methods often involve materials that are harmful to the environment, whereas 3D printing offers a more sustainable alternative by enabling the use of recycled materials and reducing waste through precise manufacturing processes.

Ethical sourcing is equally critical, as buyers are increasingly scrutinizing their supply chains. This includes ensuring that materials are sourced responsibly and that labor practices are fair and ethical. Certifications for sustainable materials, such as those indicating the use of biodegradable filaments or recycled plastics, can enhance a company’s reputation and appeal to environmentally conscious consumers.

B2B buyers should prioritize suppliers who demonstrate a commitment to sustainability and ethical practices. This not only aligns with growing consumer demand for responsible products but also mitigates risks associated with supply chain disruptions stemming from environmental regulations. By integrating sustainability into their procurement strategies, businesses can foster a positive brand image while contributing to the global effort towards environmental preservation.

What Is the Evolution of the 3D Sculpture Sector and Its Relevance to B2B Buyers?

The evolution of the 3D sculpture sector has been marked by significant technological innovations and shifts in artistic expression. Initially, sculpture was limited to traditional materials and manual craftsmanship, which posed limitations in terms of design complexity and production efficiency. However, the advent of 3D printing technology in the early 2000s revolutionized the industry, enabling artists and manufacturers to create intricate designs with unprecedented ease and speed.

As 3D printing technology matured, it began to influence not only the artistic community but also commercial applications. Today, the sector encompasses a diverse range of products, from decorative art pieces to functional sculptures used in architecture and design. This evolution is particularly relevant for B2B buyers, as it opens up new opportunities for product differentiation and market expansion.

The integration of digital design tools has further transformed the landscape, allowing businesses to collaborate more effectively and innovate rapidly. For international buyers, understanding this evolution is vital for identifying potential suppliers and products that can meet their unique market demands. Embracing the advancements in the 3D sculpture sector can provide a competitive advantage and foster long-term growth in an increasingly interconnected global economy.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d sculpture

1. How do I select the right supplier for 3D sculptures?

Selecting the right supplier involves a multi-step evaluation process. Start by researching potential suppliers’ portfolios to assess their design capabilities and quality. Request samples of their previous work to ensure they meet your quality standards. Additionally, check their reputation through reviews and testimonials from other clients. It’s also crucial to verify their production capacity and lead times to ensure they can meet your order requirements. Finally, engage in direct communication to gauge their responsiveness and willingness to collaborate on customization.2. What are the key considerations when customizing 3D sculptures?

When customizing 3D sculptures, consider the intended purpose and target audience. Discuss your vision with the supplier, including dimensions, materials, and design elements. Ensure that the supplier has the necessary technology and expertise to execute your customizations effectively. It’s also vital to request prototypes or digital mockups before final production to avoid misunderstandings. Lastly, clarify any additional costs associated with customization to stay within budget.3. What is the minimum order quantity (MOQ) for 3D sculptures?

Minimum order quantities (MOQ) can vary significantly among suppliers, depending on their production processes and materials. Some may have a low MOQ for standard designs, while custom sculptures might require higher quantities to justify production costs. It’s advisable to discuss your needs upfront with potential suppliers to understand their MOQ policies. Additionally, consider negotiating terms if your order volume is smaller than their standard requirements, as some suppliers may be flexible.4. What payment terms are typical for international B2B transactions in 3D sculpture?

Payment terms in international B2B transactions often include options like advance payments, letters of credit, or payment upon delivery. It’s common for suppliers to request a deposit (20-50%) upfront, with the balance due upon completion or prior to shipping. Always clarify payment methods accepted, such as wire transfers or credit cards, and ensure compliance with any currency exchange considerations. Establishing clear payment terms upfront can help prevent misunderstandings and facilitate smoother transactions.5. How can I ensure quality assurance for 3D sculptures?

To ensure quality assurance, establish clear specifications and standards in your contract with the supplier. Request regular updates and quality checks during the production process, including photographs or video documentation. Consider implementing a third-party inspection service, especially for larger orders, to verify that the sculptures meet your quality criteria before shipment. Additionally, having a clear returns policy can provide peace of mind in case the final product does not meet the agreed standards.6. What logistics considerations should I keep in mind when importing 3D sculptures?

When importing 3D sculptures, consider shipping options, customs duties, and import regulations specific to your country. Evaluate different shipping methods (air vs. sea) based on cost and delivery time. Ensure that your supplier packages the sculptures securely to prevent damage during transit. Familiarize yourself with local customs clearance processes and potential tariffs to avoid unexpected costs. Collaborating with a freight forwarder can simplify logistics and help navigate international shipping complexities.7. How do I handle communication with suppliers from different time zones?

Effective communication with suppliers across different time zones requires strategic planning. Utilize scheduling tools to find overlapping hours for meetings and set clear agendas to maximize efficiency. Opt for email for non-urgent communications, ensuring all parties are updated in writing. Establish a primary point of contact for streamlined communication, and consider using collaborative tools like project management software to track progress and share updates in real-time.8. What are the latest trends in 3D sculpture that I should be aware of?

Current trends in 3D sculpture include the use of sustainable materials and eco-friendly printing processes, catering to a growing demand for environmentally responsible art. There’s also a rise in interactive sculptures that incorporate technology, enhancing viewer engagement. Customization through AI-driven design tools is gaining popularity, allowing for more personalized pieces. Staying updated on these trends can help you make informed purchasing decisions and appeal to modern consumer preferences.

Top 5 3D Sculpture Manufacturers & Suppliers List

1. Printables.com – 3D Printed Sculptures

โดเมน: printables.com

ลงทะเบียน: 1996 (29 ปี)

บทนำ: Sculptures | Art & Design | 3D models | Printables.com | 3D Printed Sculptures | Busts of famous people, movie heroes statues, animal creatures, or miniatures | Trending models include: Zephyron – The Stormfang Wolf, Bonsai Tree – Minimalist, Twisted Christmas Tree, Diorama medieval Isometric, GIANT TRICERATOPS HEAD, Medusa Bust, Angry Unicorn, Gyarados Pokemon, and more.

2. Sketchfab – Free 3D Sculpture Models

โดเมน: sketchfab.com

ลงทะเบียน: 2012 (13 ปี)

บทนำ: Sculpture 3D models available for viewing and downloading for free. Categories include Animals & Pets, Architecture, Art & Abstract, Cars & Vehicles, Characters & Creatures, Cultural Heritage & History, Electronics & Gadgets, Fashion & Style, Food & Drink, Furniture & Home, Music, Nature & Plants, News & Politics, People, Places & Travel, Science & Technology, Sports & Fitness, Weapons & Military….

3. Pinterest – 3D Sculpture Ideas

โดเมน: pinterest.com

ลงทะเบียน: 2009 (16 ปี)

บทนำ: 900+ 3D / Sculpture ideas in 2025, including art lessons, sculpture teaching, and various related interests such as Art for kids, Sculpture lessons, Art classroom, Camping art, School art projects, and more. Related interests include Sculpture Project, Subtractive Sculpture, High School Sculpture, 3D Sculpture Ideas, Geometric Paper Sculpture, Kinetic Sculpture, Cardboard Sculpture, Nature-inspire…

4. 3D Wasp – Delta WASP 3MT

โดเมน: 3dwasp.com

ลงทะเบียน: 2017 (8 ปี)

บทนำ: 3D printed Art, 3D printed Sculptures, created with WASP’s 3D Printers. The Delta WASP 3MT is a large 3D printer dedicated to 3D sculpture. Applications include restoration of Cultural Property and production of Statues for Cultural Heritage. Featured projects include 3D printed ceramic sculptures, installations for exhibitions, and various artistic collaborations.

5. MakerWorld – 3D Printed Art Models

โดเมน: makerworld.com

ลงทะเบียน: 2014 (11 ปี)

บทนำ: 3D Printed Art Models available in various categories including 2D Art, Sculptures, and more. Models can be downloaded for printing and displaying. Featured models include MK1 Miner, Grinch Bowl with Santa Hat, Jack Skellington, Knitted Reindeer, Mecha Pokemon Statue, Life-Size Light-Up Baby Reindeer, Harry Potter Wand Stand, Cheeky Snowman, Starbucks Bear Cup Ornament, Steampunk Lion Head Wall Re…

Strategic Sourcing Conclusion and Outlook for 3d sculpture

In the dynamic world of 3D sculpture, strategic sourcing is essential for B2B buyers aiming to capitalize on the growing demand for unique and customizable art. By leveraging platforms that offer a wide variety of 3D models—from intricate sculptures to practical design tools—businesses can enhance their product offerings while catering to diverse aesthetic preferences across global markets. The ability to source locally produced sculptures can also reduce lead times and shipping costs, fostering sustainable practices and supporting local artisans.

As the art and design landscape evolves, the integration of cutting-edge technologies like AI and 3D printing presents unprecedented opportunities for innovation. International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should actively seek partnerships with suppliers who not only provide high-quality products but also align with their sustainability and design goals.

Illustrative image related to 3d sculpture

Looking ahead, the market for 3D sculptures is poised for significant growth. Engaging in strategic sourcing now will position your business to thrive in this competitive environment. Explore new collaborations and invest in advanced technologies to stay ahead of trends, ensuring that your offerings resonate with a global audience. Embrace the future of art—your next masterpiece awaits.

คำแถลงการณ์สำคัญและเงื่อนไขการใช้งาน

⚠️ ข้อควรระวังที่สำคัญ

ข้อมูลที่ให้ไว้ในคู่มือฉบับนี้ รวมถึงเนื้อหาเกี่ยวกับผู้ผลิต, ข้อมูลทางเทคนิค, และการวิเคราะห์ตลาด มีไว้เพื่อวัตถุประสงค์ในการให้ข้อมูลและให้ความรู้เท่านั้น ไม่ถือเป็นคำแนะนำทางการจัดซื้อ, คำแนะนำทางการเงิน, หรือคำแนะนำทางกฎหมาย

แม้ว่าเราได้พยายามอย่างเต็มที่เพื่อให้ข้อมูลมีความถูกต้องและทันเวลา แต่เราไม่รับผิดชอบต่อข้อผิดพลาด การละเว้น หรือข้อมูลที่ล้าสมัยใด ๆ ทั้งสิ้น สภาพตลาด รายละเอียดของบริษัท และมาตรฐานทางเทคนิคอาจมีการเปลี่ยนแปลงได้

ผู้ซื้อ B2B ต้องดำเนินการตรวจสอบวิเคราะห์สถานะอย่างอิสระและครอบคลุมด้วยตนเอง ก่อนตัดสินใจซื้อใด ๆ. ซึ่งรวมถึงการติดต่อผู้จัดจำหน่ายโดยตรง, การตรวจสอบการรับรอง, การขอตัวอย่าง, และการขอคำปรึกษาจากผู้เชี่ยวชาญ. ความเสี่ยงที่อาจเกิดขึ้นจากการพึ่งพาข้อมูลใด ๆ ในคู่มือฉบับนี้ เป็นความรับผิดชอบของผู้อ่านแต่เพียงผู้เดียว.