When choosing safety workwear uniforms, the fabric is crucial in determining comfort, safety, and durability. Different work environments require different fabrics, so it’s essential to understand the properties of various materials. In this guide, we will introduce 5 common types of safety workwear fabrics and offer tips on how to choose the most suitable fabric for various work environments.

1. Fire-Resistant Safety Workwear Fabrics: Protection for High-Risk Environments

In industries where workers are exposed to high temperatures, such as firefighting, electrical work, and metallurgy, safety is a top priority. Fire-resistant fabrics are designed to provide workers with protection against heat and flames, reducing the risk of burns or other injuries in case of a fire or explosion.

These fabrics are typically made from fibers that are naturally resistant to flames or treated with special fire-resistant chemicals. Fire-resistant materials such as Nomex, Kevlar, and treated cotton are commonly used. These materials are engineered to withstand high temperatures without melting, thus preventing the risk of severe burns in dangerous environments.

– Choosing Tips: When selecting fire-resistant fabrics for safety workwear, it’s important to ensure that the fabric is certified according to industry standards, such as NFPA 2112. The fabric should be lightweight yet durable, offering both comfort and protection. The garments should also have reinforced stitching and seams to prevent fire penetration. Additionally, these fabrics should be breathable to prevent overheating.

2. Acid and Alkali-Resistant Safety Workwear Fabrics: Ideal for Chemical Industries

In workplaces where workers are exposed to hazardous chemicals, such as chemical plants, laboratories, and industrial factories, safety workwear made from acid and alkali-resistant fabrics is crucial. These fabrics provide protection against corrosive chemicals that can cause serious burns, skin irritation, or long-term health issues.

Acid and alkali-resistant fabrics are treated with special coatings or made from materials like vinyl, PVC, or specialized synthetic fibers that resist chemical corrosion. These fabrics can endure the harsh effects of both acidic and alkaline substances, making them ideal for industries like chemical processing, pharmaceuticals, and cleaning services.

– Choosing Tips: The best acid and alkali-resistant fabrics are those that are both chemical-resistant and durable, ensuring that they can withstand prolonged exposure to corrosive substances. When choosing acid and alkali-resistant workwear, look for certified protective clothing that meets ASTM or EN standards. It’s also important to ensure the fabric remains flexible, comfortable, and breathable while offering full protection.

3. Standard Twill Safety Workwear Fabrics: Classic Comfort and Durability

Standard twill fabrics are commonly used in safety workwear due to their durability, comfort, and versatility. This fabric is made by weaving two yarns together in a diagonal pattern, which gives it a strong, durable finish while maintaining softness. The use of a poly-cotton blend enhances the fabric’s ability to withstand wear and tear while remaining breathable and comfortable.

Twill fabrics are ideal for a wide range of industries, including manufacturing, construction, and transportation. They provide a balance between durability and comfort, which is essential for workers who need to move freely throughout the day while being protected from abrasions or minor hazards.

– Choosing Tips: When selecting twill fabrics for safety workwear, ensure the fabric is made from a high-quality poly-cotton blend, which offers both the softness of cotton and the strength of polyester. Choose fabrics that are tightly woven to increase durability and wear resistance. It’s also important to select twill fabrics that are pre-washed for comfort and shrink resistance.

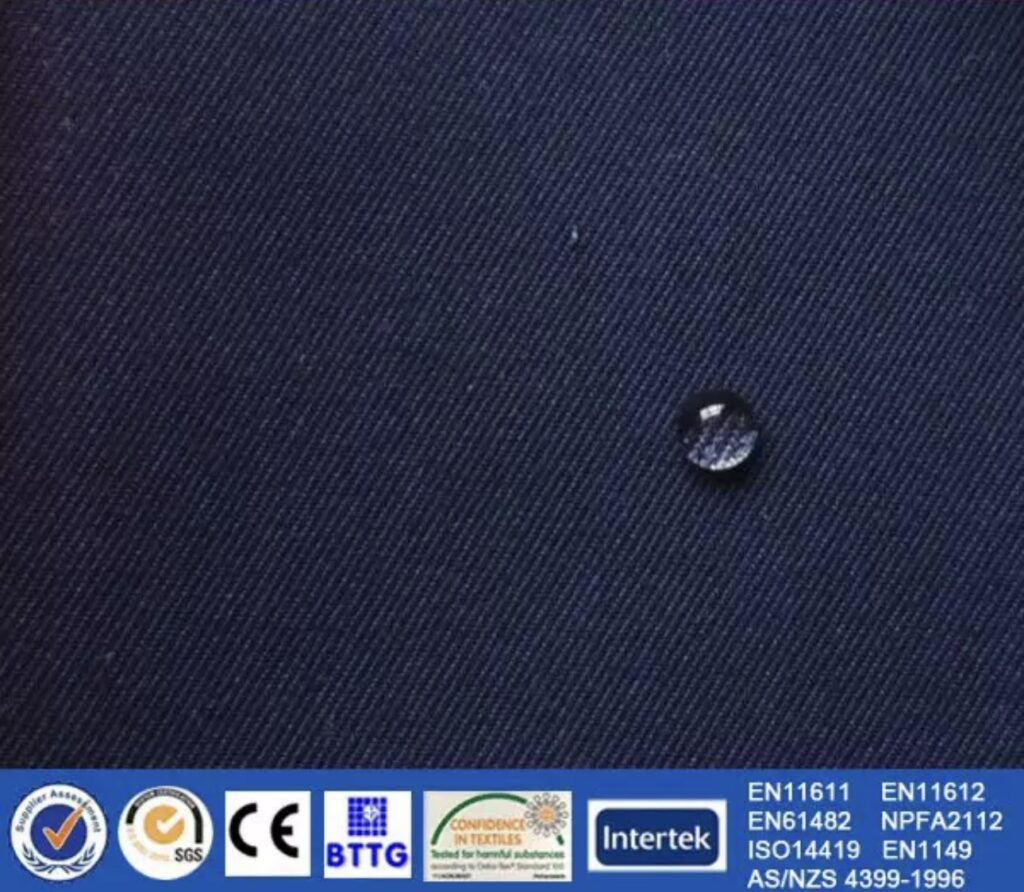

4. Waterproof Safety Workwear Fabrics: Perfect for Wet and Humid Conditions

Workplaces exposed to rainy, wet, or humid conditions require waterproof safety workwear. Whether it’s working outdoors in construction, fieldwork, or in industries like oil and gas, waterproof fabrics are crucial for keeping workers dry and protected from the elements.

Waterproof fabrics are made using materials such as coated nylon, polyurethane, or Gore-Tex, which are treated to resist water penetration while allowing moisture to escape. This breathability is key in maintaining comfort for workers, as it prevents the buildup of sweat inside the garment.

– Choosing Tips: When selecting waterproof fabrics for safety workwear, it’s essential to choose materials that offer both waterproofing and breathability. Garments should be lightweight, durable, and capable of withstanding prolonged exposure to wet conditions. Look for fabrics with sealed seams to prevent water from entering through stitching areas. Additionally, consider fabrics with UV protection if the work involves prolonged sun exposure.

5. How to Choose the Right Safety Workwear Fabric for Your Work Environment

Choosing the right fabric for safety workwear depends on several factors, including the specific work environment, the type of hazards present, and the comfort needs of the wearer. It’s essential to consider both the safety requirements and the long-term durability of the fabric.

– Comfort and Flexibility: While safety is paramount, comfort is just as important. Workwear should allow workers to move freely without restricting their movements. Fabrics that are too stiff or heavy can result in discomfort, which may reduce productivity. Choose fabrics that offer stretch and flexibility without compromising protection.

– Breathability: Fabrics that allow air circulation are key to preventing overheating, especially in physically demanding jobs. Breathable fabrics, such as poly-cotton blends and certain waterproof membranes, allow moisture to escape while keeping the worker cool and dry.

– Durability: The durability of the fabric is essential for safety workwear. Fabrics like fire-resistant materials, acid-resistant coatings, and durable twill are designed to stand up to the wear and tear of demanding work environments. When selecting safety workwear, it’s crucial to consider how often the garments will be washed, the amount of exposure to hazardous materials, and the overall lifespan of the fabric.

| ประเภทของผ้า | การประยุกต์ใช้ | Performance Features |

| Fire-Resistant | Firefighting, metallurgy, electrical industries | Fireproof, heat-resistant, flame retardant, protecting from burns |

| Acid & Alkali-Resistant | Chemical plants, laboratories | Acid/alkali resistant, durable against chemical corrosion |

| Standard Twill | Most general work environments | Durable, comfortable, breathable, ideal for everyday use |

| กันน้ำ | Construction sites, fieldwork, rainy environments | Waterproof, breathable, wash-resistant, blocks water penetration |

Summary: Choosing the Right Safety Workwear Fabric for Maximum Protection and Comfort

When selecting safety workwear, understanding the characteristics of different fabrics and choosing the right one for your specific work environment can significantly enhance both safety and comfort. Fire-resistant, acid and alkali-resistant, standard twill, and waterproof fabrics each have their unique functions and ideal applications. Choosing the right fabric is crucial for ensuring safety and comfort in any work setting.