Working in environments with slippery surfaces requires proper footwear. Slip-resistant safety shoes help improve safety and productivity. In industries like construction, healthcare, and food service, choosing reliable slip-resistant shoes is essential. TopriseSafety, a leading safety shoes factory in China, manufactures high-quality slip-resistant safety shoes for various industries. Here’s how you can select the right pair.

Causes of Slippery Surfaces

Several factors cause surfaces to become slippery. Water, oil, ice, and smooth floors reduce traction and make falls more likely. Dust or debris can also create a barrier and affect grip. Worn-out soles or chemical spills can make floors even more hazardous.

Key Features of Slip-Resistant Safety Shoes

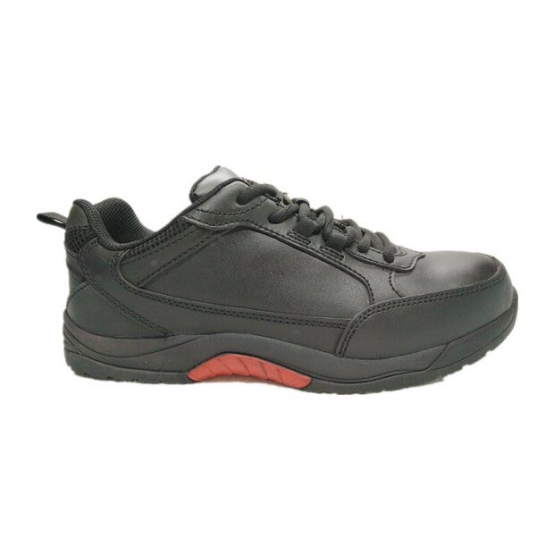

Slip-resistant safety shoes are designed to combat these hazards. They provide better traction, stability, and protection against slippery surfaces.

Material of the Outsole

Outsole material plays a crucial role in grip quality. Different materials work best for various environments.

- Rubber: This is the most common material, known for its excellent flexibility and grip. It works well on wet and oily surfaces, making it ideal for food processing and automotive industries.

- TPU (Thermoplastic Polyurethane): Lighter than rubber, TPU offers great resistance to oils and chemicals. It’s perfect for industrial settings exposed to chemicals.

- EVA (Ethylene Vinyl Acetate): Commonly used for midsoles, EVA can also provide slip resistance when paired with rubber. It’s best suited for light-duty environments needing both comfort and traction.

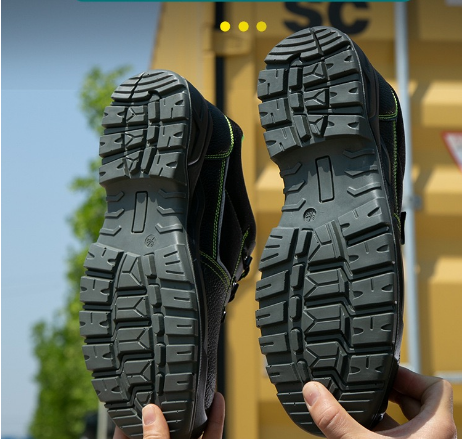

Tread Patterns

The tread pattern of a shoe affects how it interacts with the ground. Different patterns are suited to specific conditions:

- Deep Treads: Ideal for environments with mud, water, or debris. Deep grooves help drain liquids and prevent buildup, making them perfect for outdoor work.

- Shallow Treads: Better for indoor spaces like hospitals or kitchens. They offer a balance between flexibility and grip, useful for environments with frequent spills.

- Multi-Directional Tread: Offers traction in all directions, useful in settings where workers move constantly, such as logistics or manufacturing.

Siping Technology

Siped outsoles feature small cuts or slits that improve grip, particularly on wet surfaces. These cuts act like suction cups, providing extra stabili0ty. Shoes with siping are perfect for industries like food service or chemical plants.

Self-Cleaning Treads

In environments like agriculture or construction, self-cleaning treads are necessary. These treads shed mud and debris while you walk, maintaining traction by preventing the outsole from clogging.

Oil and Chemical Resistance

Industries like oil and gas, automotive, and food service deal with constant exposure to oils and chemicals. Outsoles designed with oil and chemical resistance are critical in such environments. These shoes maintain slip resistance while withstanding long-term exposure to corrosive substances.

Temperature Resistance

Regular shoes often lose flexibility in extreme heat or cold. Shoes with temperature-resistant outsoles maintain flexibility and grip in harsh environments. Cold-weather resistant shoes, for example, offer better traction on snow and ice. Here’s a table summarizing the outsole choices based on cold-weather and heat-resistant requirements:

| Outsole Type | Material | Key Features | Ideal Applications |

| Cold-Weather Resistance | Rubber | – Remains flexible in freezing temperatures. – Deep treads channel away snow and water, preventing slips. | – Outdoor work. – Construction. – Cold storage. |

| Heat-Resistant Outsoles | Specialized rubber compounds or TPU (Thermoplastic Polyurethane) | – Withstands high temperatures without melting or damage. – Resistant to heat up to specific degrees. | – Welding. – Foundries. – Work near furnaces or industrial machines. |

Durability and Weight

Slip-resistant safety shoes need to balance durability with weight. Heavy-duty rubber outsoles work well in rugged environments like construction, where durability and slip resistance are essential. In indoor settings, lightweight outsoles offer a more comfortable balance between grip and comfort.

Key Considerations When Choosing Slip-Resistant Safety Shoes

When choosing slip-resistant safety shoes, consider these factors:

- Material: Rubber outsoles offer the best slip resistance. TPU provides chemical resistance in industrial settings.

- Tread Depth: Deep treads suit outdoor and debris-heavy environments. Shallow treads are better for indoor spaces.

- Siping: Improves grip on wet or oily surfaces.

- Oil/Chemical Resistance: Essential for environments with frequent exposure to oils and chemicals.

- Temperature Resistance: Critical for cold or hot work environments.

Conclusion

Getting the right slip-resistant safety shoes involves understanding your work environment and the hazards present. TopriseSafety manufactures a wide range of slip-resistant safety shoes, tailored to various industries. Whether you need deep-tread rubber soles for outdoor work or siped outsoles for oily kitchens, the right pair of shoes can reduce accidents and ensure safety. Assess your needs carefully and get high-quality footwear for maximum safety and comfort.