Personal protective equipment (PPE) plays a crucial role in maintaining a safe work environment. PPE includes a variety of protective gear designed to shield workers from workplace hazards. These hazards can range from physical dangers like falling objects to chemical exposures. In this blog, we’ll explore what PPE is, the different types of personal protective equipment, and how personal protective equipment manufacturers help keep workers safe.

What is Personal Protective Equipment?

Personal protective equipment, often referred to as PPE, includes any equipment worn to protect workers from hazards. These hazards can be physical, chemical, biological, or even mechanical. Common examples of PPE are gloves, safety glasses, ear protection, hard hats, respirators, and protective clothing like coveralls and vests.

The main goal of PPE is to reduce exposure to risks that could cause injury or illness. Whether it’s a factory worker, a construction worker, or someone in the healthcare field, PPE helps protect employees from potential harm.

Types of PPE

PPE varies based on the type of hazards workers face. There are many types of PPE, each designed to guard against specific dangers. Below are some of the most popular types of PPE:

Head Protection

Hard hats are essential for workers in construction or manufacturing environments. They protect the head from falling objects, impacts, and electrical hazards. When selecting head protection, it’s crucial to choose helmets that meet established safety standards.

Eye and Face Protection

Workers who deal with flying particles, chemicals, or molten metal must wear eye and face protection. Safety glasses, goggles, and face shields offer vital protection. These items prevent serious eye injuries, such as cuts or burns from chemicals.

Hearing Protection

High noise levels are common in many industries. Earplugs and earmuffs aim to protect hearing. In environments like factories, construction sites, or airports, hearing protection is necessary to prevent hearing loss caused by prolonged exposure to loud sounds.

Respiratory Protection

Respirators and face masks protect workers from airborne contaminants, dust, and fumes. These are especially important in industries such as healthcare, mining, or manufacturing, where employees may be at the risks of harmful chemicals or particulate matter.

Hand Protection

Gloves are one of the most popular types of PPE. They protect workers from cuts, abrasions, chemicals, and burns. Different gloves are available for different hazards, such as rubber gloves for chemical handling or leather gloves for handling sharp objects.

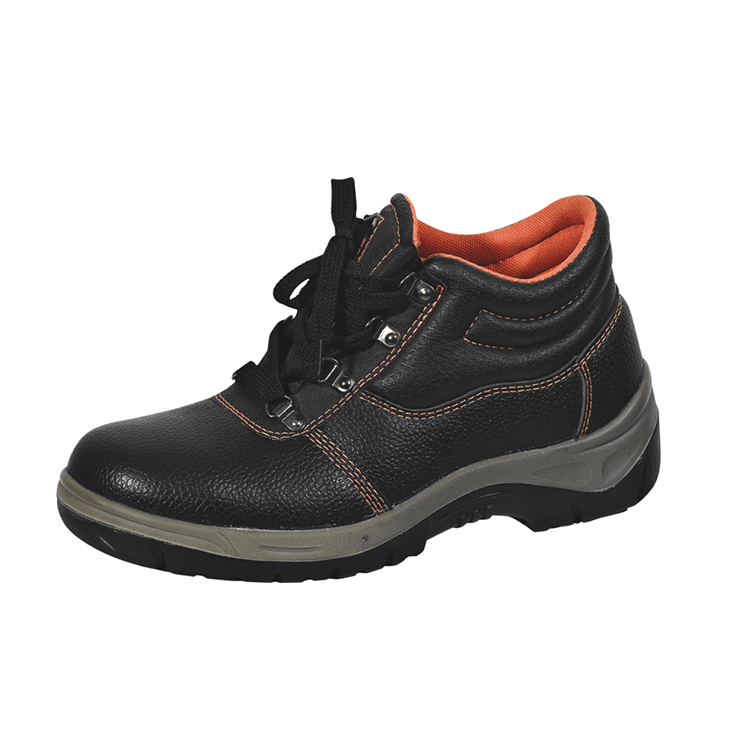

Foot Protection

Safety boots or shoes protect the feet from injuries caused by heavy objects, electrical hazards, or slips. Steel-toe boots are commonly worn in construction or manufacturing environments to prevent injuries from falling objects.

Fall Protection

In high-risk environments, workers must be aware of risks from falls. Personal fall protection systems include harnesses, lanyards, and lifelines. These are essential for workers in construction, maintenance, and roofing jobs.

Why is Personal Protective Equipment Necessary?

PPE is a critical line of defense against workplace injuries. It provides the necessary protection when engineering controls or work practices alone cannot eliminate or reduce hazards. PPE is a must by law in many industries, and employers must ensure that their workers are under great protection.

The Occupational Safety and Health Administration (OSHA) sets strict standards for the use of PPE in various industries. These regulations ensure that PPE meets specific safety criteria, helping to reduce the risk of injury or illness. Compliance with OSHA’s PPE standards is essential for creating a safe working environment.

Ensuring Proper Use of Personal Protective Equipment

To ensure that PPE is effective, use it properly. Employers and employees must follow certain steps to guarantee the PPE functions as intended. These steps include:

Proper Selection

Employers must select the appropriate PPE for the specific hazards present in the workplace. Choose PPE, based on the type of risk, such as chemical exposure, physical injury, or noise levels. Proper PPE selection ensures that workers are under adequate protection.

Fit and Comfort

For PPE to be effective, it must fit properly. Ill-fitting equipment can compromise protection and make workers less likely to use it. Employers must ensure that PPE is comfortable and adjustable, encouraging workers to wear it consistently.

Maintenance and Care

Regular maintenance and inspection of PPE are essential for ensuring its continued effectiveness. Replace the damaged or worn-out PPE immediately to prevent injuries. Train the employees in how to properly care for and maintain their PPE.

Training

Workers must be trained in when, why, and how to use PPE correctly. They should understand the importance of wearing PPE and be familiar with the limitations of the equipment. Employers should also provide guidance on the proper way to put on, adjust, and take off PPE.

Disposal and Replacement

PPE has a limited lifespan. Once it reaches the end of its useful life, it should be disposed of properly. Employers must ensure that worn-out equipment is replaced promptly to ensure ongoing worker protection.

PPE and OSHA Standards

OSHA sets specific standards for PPE use in various industries. These standards are designed to minimize workplace injuries and illnesses by ensuring the proper use of PPE. Some key regulations include:

General Industry (29 CFR 1910) The OSHA standards for general industry cover a wide range of hazards. This includes regulations for eye protection, respiratory protection, and foot protection, among others. Employers must ensure their workers wear appropriate PPE to protect against these hazards.

Construction and Maritime Standards

In addition to general industry standards, OSHA has specific PPE regulations for the construction and maritime industries. These sectors have unique hazards, such as falling debris or exposure to corrosive materials, which require specialized protective equipment.

Hazardous Materials

For industries dealing with hazardous materials, OSHA requires specific PPE to prevent exposure to harmful chemicals or biological agents. This includes chemical-resistant gloves, respirators, and full-body suits to protect workers from contamination.

Personal Fall Protection Systems

In industries where workers are exposed to fall hazards, OSHA mandates the use of personal fall protection systems. These systems include harnesses and lanyards to prevent falls and injuries.

The Role of Personal Protective Equipment Manufacturers

Personal protective equipment manufacturers play an essential role in providing high-quality safety products. These manufacturers are responsible for designing and producing PPE that meets industry standards. Personal protective equipment manufacturers in China and around the world supply a wide range of safety products, ensuring that companies have access to the gear they need to protect their workers.

Personal protective equipment manufacturers and suppliers must adhere to strict safety standards. They work to ensure that their products offer the necessary protection for a variety of workplace environments. Many PPE manufacturers also provide bulk purchasing options, such as safety products wholesale or personal protective equipment wholesale, to cater to businesses of all sizes.

Conclusion

Personal protective equipment is a vital aspect of workplace safety. It helps to minimize the risks of injuries and illnesses caused by workplace hazards. Employers must ensure the proper use, maintenance, and training for PPE to create a safe work environment. By adhering to OSHA standards and working with reliable PPE manufacturers, businesses can protect their workers and promote a culture of safety.

PPE is more than just equipment; it’s a commitment to the well-being of workers. Whether you’re looking for safety products for your company or purchasing wholesale PPE, it’s crucial to choose high-quality products that meet safety standards. Personal protective equipment manufacturers around the world continue to innovate, ensuring workers have the protection they need to stay safe on the job.