Introduction: Navigating the Global Market for how to build pergola

In today’s competitive landscape, sourcing the right materials and expertise for building a pergola can pose significant challenges for international B2B buyers. Whether you’re in Brazil, Saudi Arabia, or any other emerging market, understanding the nuances of constructing these outdoor structures is crucial for maximizing investment. This comprehensive guide on how to build a pergola delves into various types, design considerations, and applications, offering insights tailored to diverse climates and cultural preferences.

Our guide empowers businesses by providing actionable information on supplier vetting, ensuring quality materials, and estimating costs effectively. By addressing key factors such as local regulations, weather conditions, and design trends, we equip you with the knowledge necessary to make informed purchasing decisions. This is especially vital for businesses in Africa, South America, the Middle East, and Europe, where the demand for outdoor living solutions is rapidly growing.

From selecting the right type of lumber to understanding installation techniques, this resource is designed to streamline your procurement process and enhance your project outcomes. Whether you’re a contractor seeking to expand your offerings or a retailer looking to meet customer demands, this guide serves as an essential tool in navigating the global market for pergolas, ensuring you achieve quality results that resonate with your clients.

Table Of Contents

- Top 4 How To Build Pergola Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to build pergola

- Understanding how to build pergola Types and Variations

- Key Industrial Applications of how to build pergola

- 3 Common User Pain Points for ‘how to build pergola’ & Their Solutions

- Strategic Material Selection Guide for how to build pergola

- In-depth Look: Manufacturing Processes and Quality Assurance for how to build pergola

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to build pergola’

- Comprehensive Cost and Pricing Analysis for how to build pergola Sourcing

- Alternatives Analysis: Comparing how to build pergola With Other Solutions

- Essential Technical Properties and Trade Terminology for how to build pergola

- Navigating Market Dynamics and Sourcing Trends in the how to build pergola Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to build pergola

- Strategic Sourcing Conclusion and Outlook for how to build pergola

- Important Disclaimer & Terms of Use

Understanding how to build pergola Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Pergola | Classic design with vertical posts and horizontal beams | Landscaping, outdoor dining, event spaces | Pros: Timeless aesthetic; customizable. Cons: Requires maintenance; can be costly. |

| Louvered Pergola | Adjustable slats for sunlight control | Restaurants, cafes, outdoor lounges | Pros: Versatile shading options; modern appeal. Cons: More complex installation; higher cost. |

| Arched Pergola | Curved design adds visual interest | Parks, gardens, wedding venues | Pros: Unique aesthetic; enhances landscape. Cons: Limited structural capacity; may require custom fabrication. |

| Attached Pergola | Built as an extension of a building | Residential properties, commercial buildings | Pros: Increases usable space; more stable. Cons: Dependent on existing structure; potential for design limitations. |

| Retractable Pergola | Mechanism allows for opening and closing | High-end residential, luxury resorts | Pros: Maximum flexibility; ideal for varying weather. Cons: Higher initial investment; requires regular maintenance. |

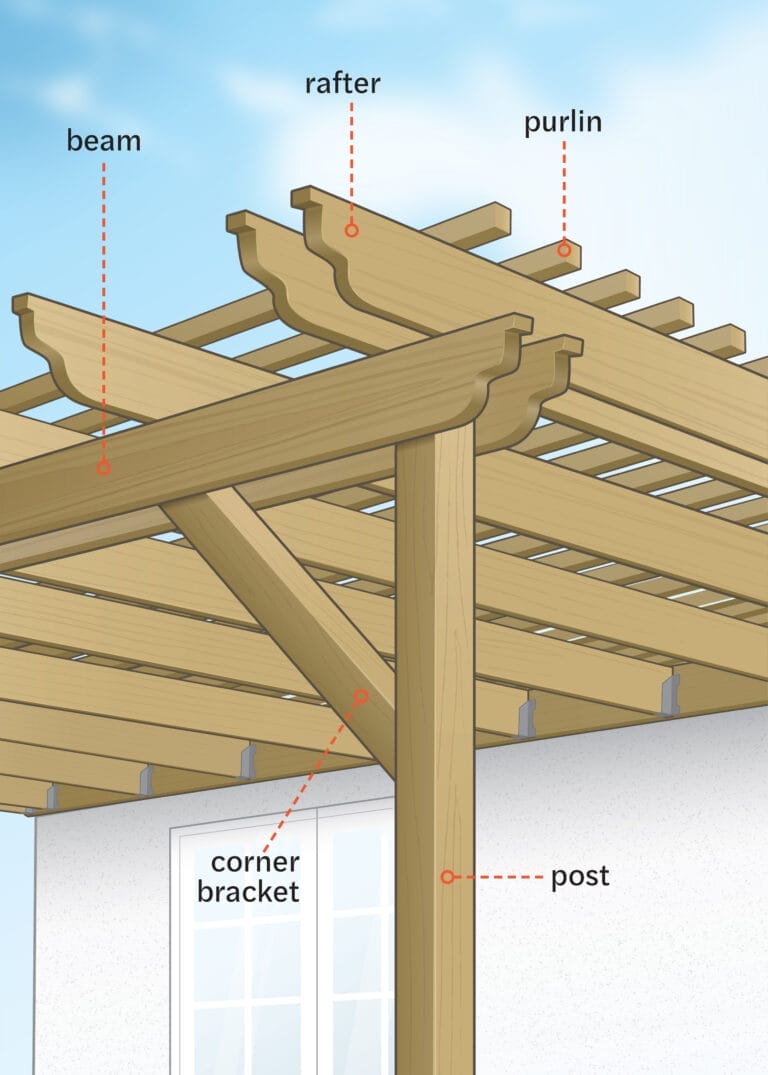

What are the Characteristics of Traditional Pergolas?

Traditional pergolas feature a straightforward design consisting of vertical posts supporting horizontal beams. This classic structure is often used in landscaping and outdoor dining spaces, providing a charming aesthetic that can be customized to fit any environment. B2B buyers should consider the longevity and maintenance costs associated with wooden materials, as well as the potential for custom designs that align with specific branding or client needs.

How Do Louvered Pergolas Offer Unique Benefits?

Louvered pergolas are distinguished by their adjustable slats, allowing users to control sunlight and shade effectively. This feature makes them particularly appealing for restaurants and outdoor lounges, where guest comfort is paramount. When purchasing, businesses should evaluate the complexity of installation and the durability of the materials used, as these factors will influence long-term maintenance and operational costs.

What Makes Arched Pergolas Stand Out?

Arched pergolas present a visually striking alternative to traditional designs, featuring curved beams that enhance the overall aesthetic appeal. They are often found in parks, gardens, and wedding venues, where visual impact is essential. B2B buyers should consider the structural integrity and potential customization options, as arched designs may require specialized craftsmanship that could affect pricing and lead times.

How Do Attached Pergolas Integrate with Existing Structures?

Attached pergolas serve as extensions of buildings, creating additional outdoor space that complements existing architecture. This design is suitable for both residential and commercial properties, making it a versatile choice for B2B buyers. It’s crucial to assess the compatibility with the current structure, as well as any necessary permits or modifications that may be required during installation.

Why Choose Retractable Pergolas for Flexibility?

Retractable pergolas are designed with mechanisms that allow the roof to open or close, offering unparalleled flexibility for outdoor spaces. Ideal for high-end residential properties and luxury resorts, they provide an elegant solution for varying weather conditions. Buyers should consider the initial investment and the need for regular maintenance, as the complexity of the retractable system can lead to increased operational costs over time.

Key Industrial Applications of how to build pergola

| Industry/Sector | Specific Application of how to build pergola | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Landscaping Services | Custom outdoor living spaces for residential clients | Enhances property value and customer satisfaction | Sourcing durable, weather-resistant materials suitable for local climates |

| Hospitality and Tourism | Outdoor dining areas and event spaces | Attracts customers and enhances guest experience | Consideration for aesthetic appeal and compliance with local building codes |

| Construction and Real Estate | Residential development projects | Increases marketability of properties with outdoor amenities | Availability of local labor and materials, as well as adherence to local regulations |

| Retail and Commercial Spaces | Outdoor retail displays and customer engagement areas | Promotes customer interaction and brand visibility | Selection of materials that align with brand image and are cost-effective |

| Event Management | Temporary or permanent event structures | Provides versatile spaces for various events | Logistics for assembly and disassembly, as well as weather considerations |

How Can Landscaping Services Utilize Pergola Construction?

Landscaping services can leverage pergola construction to create custom outdoor living spaces that enhance the aesthetic appeal of residential properties. By offering tailored designs, these businesses can significantly increase property value and customer satisfaction. Key considerations for sourcing materials include selecting durable, weather-resistant options that can withstand local climate conditions, particularly in regions like Africa and South America where weather can be unpredictable.

In What Ways Can the Hospitality and Tourism Sector Benefit from Pergolas?

The hospitality and tourism sector can benefit from building pergolas by creating inviting outdoor dining areas and event spaces. These structures not only attract customers but also enhance the overall guest experience, making establishments more appealing. When sourcing materials, businesses must consider the aesthetic appeal of the pergola, ensuring it aligns with the venue’s theme while adhering to local building codes for safety and compliance.

How Do Construction and Real Estate Companies Incorporate Pergolas?

Incorporating pergolas into residential development projects can be a strategic move for construction and real estate companies. These structures increase the marketability of properties by providing attractive outdoor amenities that appeal to potential buyers. Buyers in this sector need to consider the availability of local labor and materials, ensuring that all components meet local regulations and standards for safety and durability.

Illustrative image related to how to build pergola

What Role Do Pergolas Play in Retail and Commercial Spaces?

Retail and commercial spaces can utilize pergolas to create outdoor displays and customer engagement areas that promote interaction. These structures can enhance brand visibility and create a unique shopping experience. When sourcing materials, businesses should focus on options that not only fit within budget constraints but also align with their brand image, ensuring a cohesive look that attracts customers.

How Can Event Management Companies Leverage Pergolas for Events?

Event management companies can use pergolas to create versatile outdoor structures for both temporary and permanent events. These can serve as unique backdrops for various gatherings, enhancing the ambiance and functionality of the space. Key logistics considerations include the ease of assembly and disassembly, as well as ensuring that materials are suitable for the local weather conditions, particularly in regions with extreme climates.

3 Common User Pain Points for ‘how to build pergola’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Durable Pergolas

The Problem: B2B buyers often face challenges in sourcing high-quality materials for building pergolas, especially in regions where specific wood types or treated lumber are not readily available. For instance, buyers in Africa or South America may struggle to find pressure-treated lumber that meets international standards for durability and weather resistance. This can lead to delays in project timelines, increased costs, and ultimately, structures that do not last as long as intended.

The Solution: To overcome this issue, B2B buyers should develop relationships with reliable suppliers who specialize in outdoor construction materials. It’s essential to conduct thorough research and vet suppliers based on their product offerings, reputation, and compliance with international quality standards. Additionally, consider leveraging local distributors who can provide treated lumber suited for the specific climate conditions of the region. To ensure the longevity of the pergola, buyers should also inquire about the availability of treatments that protect against pests and moisture damage. Establishing a consistent supply chain not only mitigates risks but also enables bulk purchasing, which can lead to cost savings.

Scenario 2: Managing Installation Challenges with Limited Expertise

The Problem: Many B2B buyers may lack the expertise required for the complex installation of a pergola, especially if the design involves intricate features or specific engineering considerations. This is particularly true in markets with less access to skilled labor. Without proper installation, even the best materials can result in a structurally unsound or aesthetically unpleasing final product, leading to customer dissatisfaction.

The Solution: Buyers should consider investing in training programs or workshops for their teams to enhance their construction skills. Partnering with experienced contractors for consultation during the planning phase can also be beneficial. Additionally, providing access to detailed guides, blueprints, and instructional videos tailored for various skill levels can empower the team to handle the installation with confidence. Utilizing modular pergola kits that simplify assembly can also be an effective approach, allowing for a quicker setup while ensuring structural integrity. Finally, establishing a feedback loop post-installation can help teams learn and improve on future projects.

Scenario 3: Compliance with Local Building Codes and Regulations

The Problem: Navigating local building codes and regulations can be a significant hurdle for B2B buyers looking to construct pergolas. Compliance issues can arise from failure to meet zoning laws, safety standards, or environmental regulations, which vary widely across regions such as the Middle East and Europe. Non-compliance can lead to costly fines, project delays, or the necessity to dismantle completed work.

The Solution: B2B buyers should engage with local authorities early in the planning process to understand the specific regulations that apply to pergola construction in their area. Consulting with legal experts or construction consultants who specialize in local building codes can provide valuable insights. Furthermore, maintaining an updated knowledge base of regulations can aid in quick decision-making and project planning. It’s also advisable to document all communications with local authorities and keep records of permits and approvals to avoid complications later on. By prioritizing compliance, buyers can ensure smoother project execution and enhance their reputation in the market.

Strategic Material Selection Guide for how to build pergola

When selecting materials for building a pergola, it’s essential to consider the properties, advantages, and limitations of various options. This guide analyzes four common materials: pressure-treated lumber, cedar, aluminum, and vinyl. Each material has distinct characteristics that can influence the performance and suitability of the final product, particularly for international B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Pressure-Treated Lumber for Pergolas?

Pressure-treated lumber is a popular choice due to its enhanced durability and resistance to decay and insect damage. This material undergoes a treatment process that infuses preservatives deep into the wood fibers, making it suitable for outdoor applications. Key properties include a high moisture resistance and the ability to withstand temperature fluctuations, which is vital in regions with extreme weather conditions.

Pros: Pressure-treated lumber is relatively cost-effective, widely available, and easy to work with, making it suitable for various designs. It also provides a natural wood aesthetic that many buyers prefer.

Cons: The treatment chemicals can leach out over time, raising environmental concerns. Additionally, it may require regular maintenance, such as sealing or staining, to prolong its lifespan.

Illustrative image related to how to build pergola

How Does Cedar Compare as a Material for Pergolas?

Cedar is renowned for its natural beauty and resistance to warping, splitting, and decay. It contains natural oils that protect it from insects and moisture, making it a favorable option for outdoor structures. Cedar’s lightweight nature also makes it easy to handle during construction.

Pros: The aesthetic appeal of cedar is unmatched, providing a warm, rich color that enhances outdoor spaces. It also requires less maintenance than pressure-treated lumber due to its natural resistance to the elements.

Cons: Cedar tends to be more expensive than pressure-treated lumber, which may deter budget-conscious buyers. Additionally, it can be more susceptible to fading and weathering if not properly treated.

What Are the Advantages of Using Aluminum for Pergolas?

Aluminum is a modern alternative that offers exceptional durability and low maintenance. It is lightweight yet strong, making it easy to transport and install. Aluminum is also resistant to corrosion, which is particularly advantageous in humid or coastal environments.

Pros: The longevity of aluminum structures is a significant advantage, as they do not rot or require regular painting. Additionally, they can be powder-coated in various colors, allowing for customization.

Cons: The initial cost of aluminum can be higher than wood options. Some buyers may find the industrial look less appealing compared to traditional wood aesthetics.

What Are the Benefits and Limitations of Vinyl Pergolas?

Vinyl is a synthetic material that offers excellent durability and requires minimal maintenance. It is resistant to fading, cracking, and peeling, making it an ideal choice for long-term outdoor use. Vinyl pergolas are also available in various styles and colors.

Pros: Vinyl is easy to clean and does not require painting or staining, which can significantly reduce long-term maintenance costs. Its resistance to weathering makes it suitable for diverse climates.

Illustrative image related to how to build pergola

Cons: Vinyl may not have the same structural strength as wood or aluminum, which could limit its design capabilities. Additionally, it can be more expensive upfront compared to traditional wood options.

Summary Table of Material Selection for Pergolas

| Material | Typical Use Case for how to build pergola | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Pressure-Treated Lumber | Residential and commercial outdoor structures | Cost-effective and widely available | Requires maintenance and can leach chemicals | Medium |

| Cedar | Aesthetic-focused residential pergolas | Natural beauty and insect resistance | Higher cost and potential fading | High |

| Aluminum | Modern, low-maintenance outdoor structures | Long-lasting and customizable | Higher initial cost and industrial appearance | High |

| Vinyl | Low-maintenance residential pergolas | Minimal maintenance and weather resistance | Limited structural strength and higher upfront cost | Medium |

In conclusion, the choice of material for building a pergola should be guided by the specific needs of the project, budget constraints, and the environmental conditions of the intended location. International buyers should also consider compliance with local standards and preferences to ensure the suitability of their chosen materials.

In-depth Look: Manufacturing Processes and Quality Assurance for how to build pergola

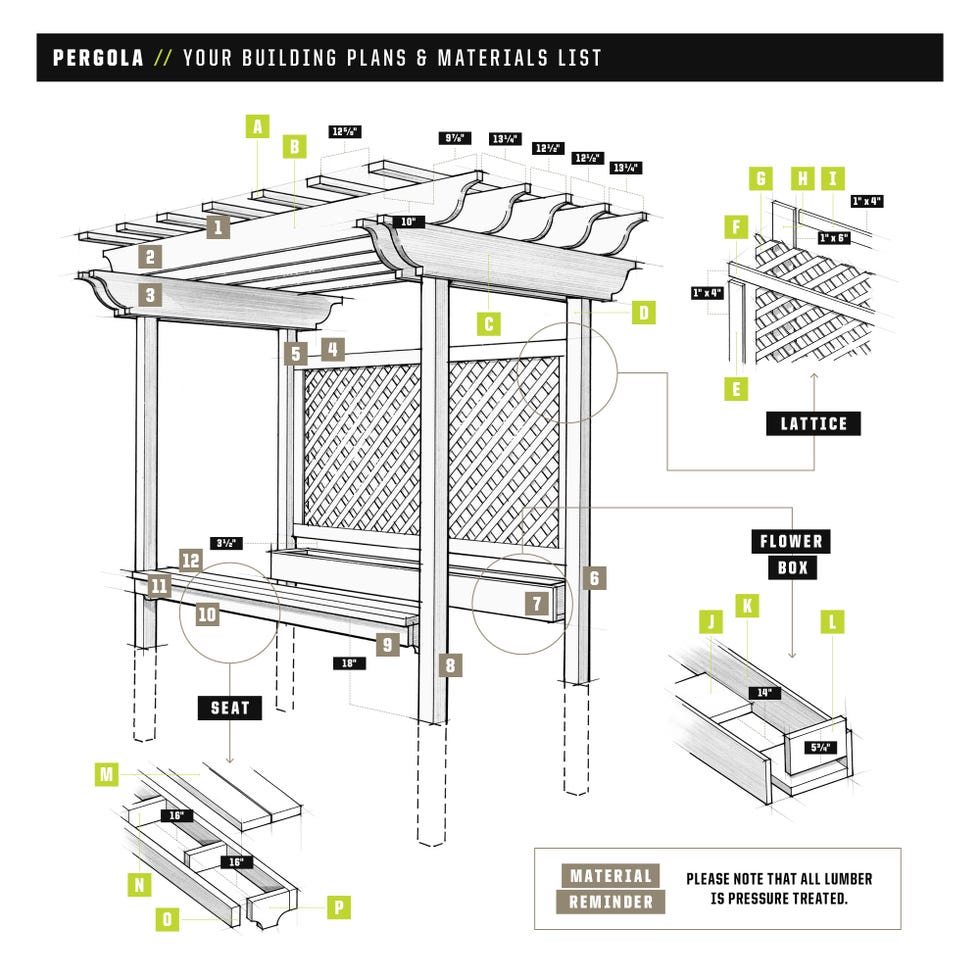

What Are the Main Stages in the Manufacturing Process for Building Pergolas?

The manufacturing process for pergolas involves several key stages, each critical to ensuring the final product meets quality and durability standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Pergola Construction?

Material preparation is the foundational step in pergola manufacturing. This stage begins with the selection of high-quality raw materials, often pressure-treated wood or durable metal, depending on the design requirements. The selected materials are then cut to size using precision saws, ensuring uniformity and adherence to design specifications.

In regions where timber is harvested, sourcing sustainably and ensuring compliance with local regulations is crucial. For instance, in Africa and South America, buyers should prioritize suppliers who adhere to sustainable forestry practices. Additionally, materials may undergo treatments to enhance their resistance to weather and pests, which is especially relevant for outdoor structures.

Illustrative image related to how to build pergola

What Techniques Are Used for Forming Pergola Components?

The forming stage involves shaping the materials into the required components. For wooden pergolas, this may include routing edges for a smooth finish or creating notches for interlocking joints. For metal pergolas, techniques such as welding or bending are employed to achieve the desired shapes.

Advanced manufacturing techniques, such as CNC (Computer Numerical Control) machining, are increasingly used to ensure precision in the shaping process. This technology allows for intricate designs while minimizing waste, which can be a significant cost-saving factor for B2B buyers.

How Is the Assembly Process Conducted for Pergolas?

Assembly is where the pergola components come together. This stage typically involves the installation of posts, beams, and cross-members, often using galvanized bolts and screws for stability. Quality assurance during assembly includes ensuring all joints are secure and aligned correctly, which is crucial for the structural integrity of the pergola.

In many cases, assembly is conducted in a controlled environment, allowing for better quality checks and less exposure to environmental factors that could affect the materials. For international B2B buyers, understanding the assembly techniques used can provide insights into the robustness of the final product.

What Are the Finishing Techniques for Pergolas?

The finishing stage enhances both the aesthetic appeal and durability of the pergola. Common techniques include staining, sealing, or painting, which not only add visual interest but also protect the materials from UV rays, moisture, and other environmental factors.

For buyers in regions with intense weather conditions, selecting suppliers who utilize high-quality finishes that comply with international standards can significantly impact the longevity of the pergola. B2B buyers should inquire about the specific finishing products used and their resistance to local climate conditions.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is an essential aspect of the manufacturing process, ensuring that the final product meets both industry standards and customer expectations. For pergola manufacturing, several international and industry-specific standards are relevant.

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a widely recognized international standard that specifies requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer has established processes to ensure consistent quality in their products. Additionally, certifications such as CE mark (European Conformity) are crucial for products sold in Europe, indicating compliance with EU safety, health, and environmental protection standards.

What Are the Key QC Checkpoints in Pergola Manufacturing?

Quality control checkpoints are implemented at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This is conducted on raw materials upon arrival at the manufacturing facility. Inspectors assess the quality and specifications of the materials to ensure they meet predefined standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to verify that processes are being followed correctly and that the components are being formed and assembled according to specifications.

-

Final Quality Control (FQC): Once the pergola is fully assembled, a comprehensive inspection is carried out. This includes checking structural integrity, finish quality, and overall aesthetics before the product is packaged for shipment.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are some actionable steps:

-

Conduct Audits: Regular audits can help assess a supplier’s adherence to quality standards. Buyers should consider scheduling on-site visits to observe manufacturing processes and QA practices.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including results from IQC, IPQC, and FQC checks. This transparency is vital for building trust.

-

Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased assessment of the manufacturing quality. This is particularly important for buyers in regions where local regulations may vary significantly.

-

Understand Certification Nuances: Different regions may have unique certifications or compliance requirements. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with these nuances to ensure compliance with local regulations.

What Common Testing Methods Are Used in Pergola Manufacturing?

Various testing methods are employed to ensure that pergolas meet safety and durability standards. Common methods include:

-

Load Testing: Assessing the structural integrity by applying weight to the pergola to ensure it can withstand environmental stresses.

-

Weather Resistance Testing: Evaluating how well the materials hold up against moisture, UV exposure, and temperature fluctuations.

-

Material Testing: This includes testing wood for strength and density, as well as metal components for corrosion resistance.

By understanding these testing methods, B2B buyers can better assess the quality and reliability of the pergolas they are considering for purchase.

Illustrative image related to how to build pergola

Conclusion

The manufacturing processes and quality assurance measures for building pergolas are critical for ensuring a durable, reliable, and aesthetically pleasing final product. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful partnerships and satisfied customers. Knowledge of international standards, quality checkpoints, and verification methods can empower buyers in their procurement strategies, especially in diverse markets across Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to build pergola’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring the necessary materials and services for building a pergola. Whether you are serving clients in Africa, South America, the Middle East, or Europe, this checklist will ensure you cover all essential steps, from selecting the right materials to evaluating suppliers.

Step 1: Define Your Project Requirements

Before initiating the procurement process, clearly outline your project’s specifications. This includes dimensions, design preferences, and the intended use of the pergola.

– Considerations: Weather conditions in your region may dictate the materials you choose, such as pressure-treated wood for durability against moisture.

– Documentation: Prepare detailed drawings or sketches to communicate your vision effectively to suppliers.

Step 2: Research and Select Quality Materials

Identifying high-quality materials is critical for the longevity and safety of the structure. Focus on sourcing pressure-treated lumber, galvanized fasteners, and appropriate concrete.

– Material Types: Assess options like cedar or redwood, which offer natural resistance to rot and pests.

– Sustainability: Consider suppliers that provide sustainably sourced materials, which can enhance your brand’s reputation in eco-conscious markets.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Supplier Verification: Check for certifications, such as ISO or local building codes, to ensure compliance with industry standards.

– Sample Orders: If feasible, order small quantities of materials to assess quality before placing larger orders.

Step 4: Obtain Competitive Quotes

Request detailed quotes from multiple suppliers to compare pricing and terms. Ensure that the quotes include all necessary materials and delivery costs.

– Cost Breakdown: Look for transparency in pricing to avoid hidden fees.

– Negotiation: Use competitive quotes to negotiate better terms or discounts, especially for bulk orders.

Step 5: Confirm Delivery and Logistics

Once you select a supplier, confirm delivery timelines and logistics. Understanding the lead times will help you plan your construction schedule effectively.

– Local Regulations: Be aware of any import regulations or tariffs that may affect delivery times and costs.

– Transportation: Consider the logistics of transporting materials from the supplier to the construction site, ensuring that the selected supplier can accommodate your needs.

Step 6: Plan for Installation and Labor

Decide whether you will handle the installation in-house or hire a contractor. If opting for external labor, ensure that the contractor has experience with pergola construction.

– Labor Agreements: Review contracts carefully, ensuring that timelines and responsibilities are clearly defined.

– Training: If using in-house labor, consider providing training on proper installation techniques to ensure quality workmanship.

Illustrative image related to how to build pergola

Step 7: Implement Quality Control Measures

Establish a quality control process to oversee the materials and construction at various stages. This will help identify issues early and ensure that the final product meets your standards.

– Inspections: Schedule inspections during key phases of construction to ensure compliance with your design specifications.

– Feedback Loop: Create a system for collecting feedback from your installation team to continuously improve the process for future projects.

By following these steps, B2B buyers can efficiently procure the necessary materials and services to build a high-quality pergola that meets their clients’ needs.

Comprehensive Cost and Pricing Analysis for how to build pergola Sourcing

What Are the Key Cost Components for Building a Pergola?

When considering the construction of a pergola, several cost components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

Materials are the most significant expense, typically accounting for 50-60% of the total cost. Depending on the design and location, options range from pressure-treated lumber to high-end materials like cedar or composite wood. The choice of materials significantly impacts durability and aesthetics, which can influence long-term maintenance costs.

Labor costs can vary widely based on the complexity of the design and regional wage standards. For instance, hiring skilled labor in Europe may be costlier than in South America or Africa. Labor costs can range from 20-30% of the total project cost, particularly if the construction requires specialized skills.

Manufacturing overhead and tooling costs are generally less visible but important. These include expenses associated with the equipment and facilities used for production, which can add an additional 10-15% to the overall cost.

Quality control (QC) processes ensure that the materials meet required standards, which can incur further expenses. Ensuring compliance with international standards may be crucial for buyers in markets like the Middle East and Europe, where regulations can be stringent.

Logistics costs encompass transportation and storage, which can vary based on distance and shipping methods. This is especially relevant for international buyers who may need to consider customs duties and import taxes.

Illustrative image related to how to build pergola

Finally, the margin that suppliers add to their pricing will depend on market conditions and competitive factors, typically around 10-20%.

How Do Price Influencers Affect Pergola Sourcing?

Several factors can influence the pricing structure for pergola sourcing. Volume and minimum order quantities (MOQ) are critical; larger orders may attract discounts, while smaller orders can incur higher per-unit costs.

Specifications and customization also play a role. Standardized designs are often more cost-effective than custom builds, which require additional design and manufacturing time.

The quality of materials significantly affects pricing. High-quality, certified materials may come at a premium but can lead to lower long-term maintenance costs. For instance, pressure-treated lumber is often more expensive upfront but offers longevity and resistance to weather-related damage.

Illustrative image related to how to build pergola

Supplier factors such as reputation and reliability can also influence costs. Established suppliers with a track record may command higher prices due to perceived quality assurance.

Lastly, Incoterms dictate the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for international buyers to avoid unexpected costs related to shipping and customs.

What Buyer Tips Can Enhance Cost-Efficiency in Pergola Sourcing?

To optimize costs when sourcing pergolas, consider the following strategies:

-

Negotiate Pricing: Leverage bulk purchasing or long-term contracts to negotiate better pricing. Suppliers may be willing to offer discounts for larger volumes or repeat business.

-

Evaluate Total Cost of Ownership (TCO): Focus on the long-term costs associated with materials and labor, including maintenance and replacement. Sometimes, a higher initial investment in quality materials can lead to lower TCO.

-

Understand Regional Pricing Nuances: Pricing can vary significantly across regions due to local economic conditions, labor costs, and material availability. Buyers in Africa and South America may find more cost-effective options locally, whereas European buyers may need to consider compliance costs.

-

Research Supplier Capabilities: Assess the suppliers’ production capabilities and their ability to meet specific customization needs. This can prevent costly delays and ensure quality.

-

Stay Informed on Market Trends: Keeping abreast of trends in pergola design and material advancements can help buyers make informed decisions, potentially leading to cost savings.

Disclaimer on Indicative Prices

It is important to note that prices are indicative and can fluctuate based on market conditions, supplier changes, and economic factors. Always request updated quotes and conduct thorough due diligence before finalizing any agreements.

Illustrative image related to how to build pergola

Alternatives Analysis: Comparing how to build pergola With Other Solutions

Introduction: Exploring Alternatives to Building a Pergola

When considering outdoor structures for shade and aesthetic appeal, building a pergola is a popular choice. However, various alternative solutions can provide similar benefits, each with its unique set of features, costs, and implementation requirements. This analysis will compare the traditional method of building a pergola with alternatives such as purchasing a pre-fabricated pergola kit and installing a retractable awning. Understanding these options can help B2B buyers make informed decisions that align with their project goals and budget constraints.

Comparison Table

| Comparison Aspect | How To Build Pergola | Pre-Fabricated Pergola Kit | Retractable Awning |

|---|---|---|---|

| Performance | Durable and customizable | Quick assembly; less durable | Flexible shade control |

| Cost | Moderate; labor-intensive | Higher upfront cost | Variable; installation may add cost |

| Ease of Implementation | Requires woodworking skills | Easy; minimal tools needed | Moderate; some skills required |

| Maintenance | Moderate; regular upkeep needed | Low; depends on material | Low; may require occasional cleaning |

| Best Use Case | Long-term structures, custom designs | Quick setups, standard sizes | Temporary shade, variable use |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Pre-Fabricated Pergola Kits?

Pre-fabricated pergola kits offer a convenient solution for those seeking to avoid the complexities of building a structure from scratch. These kits typically come with all necessary materials and step-by-step instructions, allowing for quick assembly. However, while they save time and labor costs, the customization options may be limited, and the quality of materials can vary significantly. For businesses looking for a rapid installation without the need for complex design considerations, pre-fabricated kits can be an effective solution.

How Do Retractable Awnings Compare in Terms of Functionality?

Retractable awnings provide a flexible shading solution that can be adjusted based on weather conditions or personal preference. They are ideal for businesses that need temporary shade and want to maximize outdoor space use, such as restaurants or event venues. While they generally require less maintenance and installation time than a pergola, they may not offer the same level of durability or aesthetic appeal. Additionally, the cost can vary based on size and features, making it essential for buyers to assess their long-term needs and budget.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Outdoor Shade Needs?

Selecting the right outdoor shade solution involves evaluating specific business needs, budget constraints, and desired aesthetics. For companies seeking a permanent, customizable structure, building a pergola remains a strong option. Conversely, if speed and simplicity are priorities, pre-fabricated kits or retractable awnings may be more suitable. Ultimately, understanding the pros and cons of each solution will empower B2B buyers to make strategic decisions that enhance their outdoor environments while meeting operational requirements.

Essential Technical Properties and Trade Terminology for how to build pergola

What Are the Key Technical Properties for Building a Pergola?

When constructing a pergola, understanding the essential technical properties is crucial for ensuring durability, safety, and aesthetic appeal. Here are some critical specifications to consider:

-

Material Grade

– Definition: This refers to the quality and specifications of the materials used, such as pressure-treated lumber, cedar, or composite materials.

– B2B Importance: Selecting the right material grade is vital for longevity and performance. For instance, pressure-treated lumber is resistant to rot and insects, making it ideal for outdoor structures. Buyers need to ensure that the materials meet local building codes and environmental standards. -

Load-Bearing Capacity

– Definition: This is the maximum weight a pergola can support, which includes the structure itself and any additional loads such as climbing plants or snow.

– B2B Importance: Understanding load-bearing capacity helps in designing a pergola that can withstand local weather conditions and usage demands. This is especially important for businesses in areas with heavy snowfall or high winds, as inadequate load capacity can lead to structural failures. -

Tolerance Levels

– Definition: This refers to the allowable variation in dimensions of the materials used, such as the width of beams or height of posts.

– B2B Importance: Precise tolerances are essential for ensuring that components fit together correctly during assembly. Misalignment can lead to structural weaknesses or aesthetic issues. For international buyers, ensuring that tolerance levels comply with local manufacturing standards is critical. -

Finish and Treatment

– Definition: The coatings or treatments applied to wood or other materials to protect against weathering, UV rays, and pests.

– B2B Importance: Proper finishing extends the lifespan of a pergola and reduces maintenance costs. Buyers should consider finishes that comply with environmental regulations in their region to avoid potential penalties. -

Dimensional Specifications

– Definition: The specific measurements of the pergola components, such as beam width, post height, and spacing between cross members.

– B2B Importance: Accurate dimensional specifications are crucial for ensuring structural integrity and aesthetic consistency. Buyers must ensure that these specifications align with their design requirements and local building codes.

Which Trade Terms Are Commonly Used in Pergola Construction?

Familiarity with industry terminology can facilitate smoother transactions and better communication among stakeholders. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers source high-quality components for their pergola projects, ensuring that they meet specific design and performance criteria. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Knowing the MOQ can assist businesses in managing inventory costs and negotiating better terms with suppliers. This is particularly relevant for large-scale projects where bulk purchasing may be necessary. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to invite suppliers to submit price proposals for specific products or services.

– Importance: An RFQ is essential for obtaining competitive pricing and understanding market conditions. This process helps buyers ensure they are getting the best value for their pergola construction needs. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is crucial for international buyers, as it clarifies shipping responsibilities, costs, and risk management. This knowledge helps in making informed decisions about logistics and supply chain management. -

Lead Time

– Definition: The time taken from placing an order until the goods are delivered.

– Importance: Understanding lead times allows businesses to plan their projects effectively. This is especially important for seasonal outdoor projects, where timing can significantly impact overall project success.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance the quality and efficiency of their pergola construction projects.

Navigating Market Dynamics and Sourcing Trends in the how to build pergola Sector

What Are the Current Market Dynamics and Key Trends in the Pergola Construction Sector?

The pergola construction sector is experiencing significant growth driven by increasing demand for outdoor living spaces. As urbanization continues, particularly in regions such as Africa, South America, the Middle East, and Europe, homeowners and businesses are looking to enhance their outdoor environments. This trend is supported by a growing focus on leisure and wellness, where outdoor areas are seen as extensions of living spaces. Emerging technologies, such as prefabrication and modular construction, are reshaping how pergolas are designed and built, allowing for quicker installation and reduced labor costs.

International B2B buyers are increasingly utilizing digital platforms for sourcing materials and services, streamlining procurement processes. E-commerce solutions and online marketplaces are becoming vital tools for buyers seeking competitive pricing and a diverse range of options. Additionally, the integration of augmented reality (AR) tools is allowing customers to visualize pergola designs in their spaces before committing to purchases, enhancing customer satisfaction and reducing return rates.

How Can Sustainability and Ethical Sourcing Impact the Pergola Construction Sector?

Sustainability has become a cornerstone of modern construction practices, and the pergola sector is no exception. The environmental impact of building materials is at the forefront of consumers’ minds, driving demand for sustainably sourced wood and eco-friendly materials. Buyers are increasingly prioritizing suppliers who can demonstrate responsible sourcing practices, such as certifications from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI). These certifications assure buyers that the materials used in pergola construction are harvested sustainably, minimizing deforestation and promoting biodiversity.

Illustrative image related to how to build pergola

Furthermore, the importance of ethical supply chains is gaining traction. Buyers are now seeking manufacturers that adhere to ethical labor practices and transparency in their sourcing methods. This trend not only supports local economies but also aligns with the values of environmentally conscious consumers. As a result, B2B buyers are encouraged to collaborate with suppliers who prioritize sustainability and ethical practices, ultimately contributing to a more responsible construction industry.

What Is the Brief History of Pergola Construction?

Pergolas have a rich historical background, tracing their origins back to ancient Rome and Greece, where they were used to support climbing plants and create shaded walkways in gardens. Initially, these structures were made from stone and wood, serving both aesthetic and functional purposes. Over time, pergolas evolved in design and material usage, becoming popular in various cultures worldwide.

In the modern era, pergolas have transformed into versatile outdoor structures that complement residential and commercial landscapes. With advancements in materials and construction techniques, pergolas are now available in an array of styles, from traditional to contemporary designs, catering to diverse consumer preferences. This evolution reflects the growing trend towards enhancing outdoor spaces, making pergolas a sought-after feature in landscaping and architecture. For B2B buyers, understanding this historical context can inform decisions regarding design trends and material selection, ensuring alignment with current market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of how to build pergola

-

How do I choose the right materials for building a pergola?

Selecting the appropriate materials is crucial for the longevity and aesthetic of your pergola. Pressure-treated lumber is a popular choice due to its durability against the elements, especially in outdoor settings. When sourcing materials, consider local availability and climate conditions; for example, hardwoods might be preferred in humid regions for their resistance to decay. Additionally, check for certifications that ensure sustainable sourcing and quality, which can enhance your brand reputation in international markets. -

What are the best design practices for a pergola in different climates?

Designing a pergola requires understanding the local climate. In areas with heavy rainfall or snow, ensure that the structure has proper drainage and is built with sturdy materials to withstand weight. For hot climates, consider adding shade elements or adjustable slats to provide relief from the sun. Engaging with local architects or builders familiar with regional conditions can help you create a design that is both functional and appealing. -

What should I look for when vetting suppliers for pergola materials?

When vetting suppliers, prioritize those with a strong reputation in the industry and positive client reviews. Verify their certifications and compliance with international quality standards, such as ISO or ASTM. Evaluate their capacity to fulfill orders, especially if you have specific material requirements or large volumes. Additionally, consider their logistics capabilities, ensuring they can efficiently deliver to your region while adhering to local regulations. -

What are the minimum order quantities (MOQ) for pergola components?

Minimum order quantities can vary significantly between suppliers. It’s essential to inquire about MOQs, especially when sourcing internationally. Some suppliers may offer flexible options for smaller orders, while others may have strict MOQs that reflect their production capabilities. Understanding these requirements upfront can help you manage costs and inventory effectively, particularly if you’re entering new markets. -

What payment terms are commonly accepted in international B2B transactions for pergola materials?

Payment terms can vary based on the supplier’s policies and the nature of the transaction. Common terms include advance payment, letters of credit, or payment upon delivery. It’s vital to negotiate terms that align with your cash flow and risk tolerance. Ensure that the payment method is secure and provides adequate protection against fraud, especially in cross-border transactions where currency fluctuations may impact costs. -

How can I ensure quality assurance (QA) for my pergola materials?

Implementing a robust quality assurance process is key to ensuring that the materials meet your specifications. Request samples before placing bulk orders and conduct thorough inspections upon delivery. Establish clear quality criteria with your supplier, including dimensions, finish, and durability. Consider third-party inspection services, particularly for international shipments, to verify compliance with your standards and reduce the risk of defects. -

What logistics considerations should I keep in mind when sourcing pergola materials internationally?

When sourcing materials internationally, logistics play a critical role in ensuring timely delivery. Assess shipping options, including freight forwarding and customs clearance processes. Factor in lead times for production and shipping, especially if you’re working on a tight schedule. Additionally, consider the potential for tariffs and import duties that could affect your overall budget, and choose suppliers that can assist with logistics management. -

How can I customize pergola designs to meet specific client needs?

Customization can enhance client satisfaction and differentiate your offerings in the market. Engage with clients early in the design process to understand their preferences and requirements. Offer a range of materials, colors, and finishes, and be open to incorporating unique design elements. Utilize design software to create visual renderings, allowing clients to visualize their pergola before construction. This collaborative approach not only fosters trust but also leads to tailored solutions that meet diverse client needs.

Top 4 How To Build Pergola Manufacturers & Suppliers List

1. Instructables – Pressure Treated Lumber Kits

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Materials: 6 – 6x6x12 Pressure treated Lumber, 4 – 2x8x20 Pressure Treated Lumber, 24 – 4x4x12 Pressure Treated Lumber, 12 – 1x2x8 Pine, 4 – 2x3x12 Studs, 16 – 10″ galvanized bolts, 1 Box of Galvanized washers, 1 Box of Galvanized nuts, 5 pounds of 3 1/2″ coated decking screws, 6 – 50 pound bags of gravel, 18 – 90 pound bags of concrete. Tools: Circular Saw, Miter Saw, Cordless Drill and Impact Dr…

2. Reddit – Pergola Construction

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Pergola, wood construction, 4×4 or 6×6 posts, dimensions approximately 14′ W x 10′ H, durable vinyl liner for roof.

3. Jen Woodhouse – Structural Hardware Solutions

Domain: jenwoodhouse.com

Registered: 2004 (21 years)

Introduction: 6×6 Flat T Strap, 6×6 Deck Joist Ties, 3 1/2-inch Structural Screws, Hex Head Washers, 90º Angles

4. The Spruce – DIY Pergola Plans

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: 14 free DIY pergola plans available for various styles and materials, including wood and aluminum. Options for attached or freestanding designs, with features like louvered or static slats and canopies for extra protection. Plans include building instructions, tool and material lists, diagrams, and photos. Specific plans include: 1. Free-Standing Wood Pergola (10×8 footprint, simple design) 2. Sim…

Strategic Sourcing Conclusion and Outlook for how to build pergola

Strategic sourcing for building a pergola is pivotal in ensuring not only the quality of materials but also the efficiency of the construction process. By prioritizing reliable suppliers and leveraging local resources, businesses can significantly reduce costs and improve project timelines. Key takeaways include the importance of selecting pressure-treated lumber for durability, understanding regional climate impacts on design, and utilizing local suppliers to minimize logistics challenges.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe consider their next construction projects, the strategic sourcing of materials becomes crucial. It is essential to build relationships with suppliers who understand local regulations and market demands, ensuring compliance and responsiveness to fluctuating needs.

Looking ahead, the demand for outdoor living spaces, including pergolas, is expected to rise, driven by evolving consumer preferences for enhanced outdoor experiences. By engaging in strategic sourcing now, businesses can position themselves advantageously in this growing market. Embrace this opportunity to innovate and expand your offerings, and take the first step towards elevating your projects by sourcing sustainably and effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how to build pergola