Introduction: Navigating the Global Market for aluminum pergola

In an increasingly competitive global market, sourcing high-quality aluminum pergolas presents a unique challenge for B2B buyers, particularly those operating in diverse climates across Africa, South America, the Middle East, and Europe, including nations like Saudi Arabia and Nigeria. The demand for versatile outdoor structures that combine aesthetic appeal with practical functionality is on the rise. This guide aims to equip international buyers with the essential knowledge to navigate the complexities of the aluminum pergola market, addressing critical aspects such as types, applications, supplier vetting, and cost considerations.

Aluminum pergolas are not merely decorative; they serve as vital enhancements to outdoor living spaces, offering adjustable features like louvered roofs that provide optimal shade and ventilation. By understanding the various styles and functionalities available, buyers can make informed decisions that align with their specific project requirements and regional preferences. Furthermore, this guide will delve into supplier assessments, helping you identify reliable manufacturers and distributors who can meet your quality standards and logistical needs.

By leveraging the insights provided in this comprehensive resource, B2B buyers will be empowered to make strategic purchasing decisions that enhance their offerings, satisfy their clientele, and ultimately boost their bottom line. Embrace the opportunity to elevate your outdoor spaces with innovative aluminum pergolas tailored to your market’s demands.

Table Of Contents

- Top 6 Aluminum Pergola Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for aluminum pergola

- Understanding aluminum pergola Types and Variations

- Key Industrial Applications of aluminum pergola

- 3 Common User Pain Points for ‘aluminum pergola’ & Their Solutions

- Strategic Material Selection Guide for aluminum pergola

- In-depth Look: Manufacturing Processes and Quality Assurance for aluminum pergola

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum pergola’

- Comprehensive Cost and Pricing Analysis for aluminum pergola Sourcing

- Alternatives Analysis: Comparing aluminum pergola With Other Solutions

- Essential Technical Properties and Trade Terminology for aluminum pergola

- Navigating Market Dynamics and Sourcing Trends in the aluminum pergola Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of aluminum pergola

- Strategic Sourcing Conclusion and Outlook for aluminum pergola

- Important Disclaimer & Terms of Use

Understanding aluminum pergola Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Louvered Pergola | Adjustable louvers for sunlight and ventilation control | Restaurants, hotels, outdoor event spaces | Pros: Versatile shading; modern design. Cons: Higher cost compared to fixed options. |

| Solid Roof Pergola | Fixed solid roof for complete shade and protection | Residential properties, commercial spaces | Pros: Durable; excellent rain protection. Cons: Less flexibility in light control. |

| Hybrid Pergola | Combination of aluminum and wood grain finishes | Luxury homes, upscale restaurants | Pros: Aesthetic appeal; blends natural look with durability. Cons: Potentially higher maintenance. |

| Freestanding Pergola | Standalone structure not attached to buildings | Gardens, parks, outdoor recreational areas | Pros: Flexible placement; enhances outdoor aesthetics. Cons: Requires more space. |

| Wall-Mounted Pergola | Attached to a building for space efficiency | Patios, balconies, small outdoor areas | Pros: Space-saving; easy installation. Cons: Limited to existing structure aesthetics. |

What Are the Characteristics of Louvered Pergolas?

Louvered pergolas feature adjustable louvers that allow users to control the amount of sunlight and airflow, making them ideal for various weather conditions. This type is particularly suitable for B2B applications in hospitality settings, such as restaurants and hotels, where outdoor dining spaces benefit from versatile shading. When considering a louvered pergola, buyers should evaluate the quality of the adjustable mechanism, overall durability, and potential for customization to fit specific branding needs.

Illustrative image related to aluminum pergola

How Do Solid Roof Pergolas Differ from Other Types?

Solid roof pergolas provide a fixed overhead structure that offers complete protection from rain and harsh sunlight. This makes them well-suited for residential and commercial applications where consistent weather protection is essential, such as in outdoor lounges or event spaces. Buyers should consider the material quality, insulation properties, and design options to ensure that the solid roof pergola meets their aesthetic and functional requirements.

What Makes Hybrid Pergolas a Popular Choice?

Hybrid pergolas combine aluminum with wood grain finishes, providing a modern yet natural aesthetic. They are often used in luxury homes and upscale restaurants where visual appeal is a priority. When purchasing hybrid pergolas, businesses should assess the durability of the materials, maintenance requirements, and how well the design integrates with existing landscapes to enhance overall outdoor ambiance.

Why Choose Freestanding Pergolas for Outdoor Spaces?

Freestanding pergolas are standalone structures that can be placed anywhere in an outdoor area, making them highly versatile. They are commonly used in gardens, parks, and recreational areas to create inviting spaces. B2B buyers should consider the size and design options available, as well as how the structure will complement the surrounding landscape, to maximize the aesthetic impact.

What Are the Benefits of Wall-Mounted Pergolas?

Wall-mounted pergolas attach directly to a building, making them an excellent choice for maximizing limited outdoor space, such as patios or balconies. They are particularly useful in urban environments where space is at a premium. Buyers should evaluate the ease of installation, compatibility with existing structures, and design flexibility to ensure that the wall-mounted pergola meets their functional and aesthetic needs.

Illustrative image related to aluminum pergola

Key Industrial Applications of aluminum pergola

| Industry/Sector | Specific Application of aluminum pergola | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Tourism | Outdoor dining areas in restaurants and cafes | Enhances guest experience and increases seating capacity | Durability, design flexibility, and ease of installation |

| Real Estate & Property Development | Residential and commercial outdoor spaces | Increases property value and enhances curb appeal | Customization options and compliance with local regulations |

| Retail | Shade structures for outdoor retail spaces | Attracts customers and improves shopping experience | Weather resistance and aesthetic compatibility with branding |

| Event Management | Temporary or permanent structures for outdoor events | Provides comfort and shelter for guests, enhancing event quality | Portability and ease of assembly/disassembly |

| Landscaping & Architecture | Integration into landscape designs for parks and gardens | Adds functionality and aesthetic appeal to outdoor environments | Eco-friendliness and material sustainability |

How Are Aluminum Pergolas Used in the Hospitality & Tourism Industry?

In the hospitality sector, aluminum pergolas are increasingly utilized to create inviting outdoor dining areas for restaurants and cafes. These structures provide shade and comfort, allowing establishments to maximize their seating capacity while enhancing the overall guest experience. Buyers in this sector should prioritize durability and design flexibility, ensuring that the pergolas can withstand diverse weather conditions and blend seamlessly with the venue’s aesthetic. Additionally, ease of installation is vital for minimizing disruption during peak business hours.

What Role Do Aluminum Pergolas Play in Real Estate & Property Development?

Aluminum pergolas are commonly employed in residential and commercial properties to enhance outdoor spaces. By adding these structures, property developers can significantly increase the value and appeal of their projects. Buyers in this industry often seek customization options that align with specific architectural styles and local regulations. Understanding the importance of aesthetic appeal and functional design can help developers attract potential buyers or tenants, making aluminum pergolas a strategic investment.

How Do Retailers Benefit from Aluminum Pergolas?

In retail environments, aluminum pergolas serve as effective shade structures for outdoor shopping areas, enhancing the overall customer experience. These installations not only provide comfort but also contribute to creating an attractive shopping atmosphere, encouraging longer visits. Retail buyers should consider weather resistance and how the pergola’s design can complement their brand image. Effective sourcing involves selecting suppliers who understand the nuances of retail environments and can offer tailored solutions.

Why Are Aluminum Pergolas Essential for Event Management?

For event management companies, aluminum pergolas are crucial for creating versatile outdoor spaces for various events, from weddings to corporate gatherings. These structures offer shelter and comfort, ensuring guests enjoy the event regardless of weather conditions. Buyers in this sector need to focus on portability and ease of assembly, as many events require quick setup and takedown. Selecting pergolas that can be easily transported and assembled will enhance operational efficiency and improve client satisfaction.

Illustrative image related to aluminum pergola

How Are Aluminum Pergolas Integrated into Landscaping & Architecture?

In landscaping and architectural projects, aluminum pergolas are integrated into designs to enhance the functionality and aesthetic appeal of parks, gardens, and outdoor spaces. These structures provide shaded areas for relaxation and gatherings, promoting outdoor activities. Buyers in this field should prioritize eco-friendliness and material sustainability, as many clients are becoming increasingly conscious of environmental impacts. Collaborating with suppliers who offer sustainable options can help landscape architects meet client demands while adhering to modern design principles.

3 Common User Pain Points for ‘aluminum pergola’ & Their Solutions

Scenario 1: Navigating Structural and Design Compatibility for Aluminum Pergolas

The Problem: B2B buyers often struggle with ensuring that aluminum pergolas are compatible with existing architectural designs and outdoor spaces. This challenge is particularly pronounced in regions with diverse climates and unique architectural styles, such as in Africa and the Middle East. Buyers may face concerns regarding the structural integrity of the pergola in extreme weather conditions, as well as aesthetic discrepancies when attempting to integrate modern aluminum designs with traditional building styles.

The Solution: To overcome these compatibility issues, buyers should conduct a thorough site analysis before purchasing an aluminum pergola. Engaging local architects or structural engineers can provide insights into the specific requirements based on local climate conditions and architectural norms. When sourcing aluminum pergolas, consider models with adjustable features, such as louvered roofs, which offer flexibility in design and functionality. Additionally, selecting a reputable manufacturer that provides customizable options can ensure that the pergola complements the existing structures while meeting local safety regulations. Collaborating with suppliers who understand regional aesthetics can also help achieve a harmonious integration into the outdoor environment.

Scenario 2: Addressing Maintenance Concerns for Aluminum Pergolas

The Problem: One common pain point for buyers is the perceived high maintenance and upkeep associated with aluminum pergolas, especially compared to traditional wooden structures. B2B buyers may fear that, despite their initial investment, they will face ongoing costs and time commitments for maintenance, leading to dissatisfaction with their purchase.

Illustrative image related to aluminum pergola

The Solution: Aluminum pergolas are designed to be low-maintenance, but it is essential to educate buyers on proper care techniques to maximize their longevity. Suppliers should provide comprehensive maintenance guides that outline simple cleaning protocols, such as using mild soap and water, to prevent dirt buildup and corrosion. Additionally, emphasizing the inherent benefits of aluminum—like its resistance to rust, rot, and pests—can alleviate concerns about maintenance. Offering warranties that cover structural integrity and finish can also instill confidence in buyers, ensuring them that their investment is protected. Providing a periodic maintenance service can further ease buyer concerns, making it a part of the purchasing package.

Scenario 3: Understanding Cost Implications and ROI of Aluminum Pergolas

The Problem: B2B buyers frequently grapple with understanding the cost implications of investing in aluminum pergolas versus other materials. They may feel uncertain about the return on investment (ROI) these structures can provide, particularly in competitive markets where budget constraints are a primary concern. This uncertainty can lead to hesitation in making a purchase decision.

The Solution: To address cost concerns, it is crucial for buyers to conduct a thorough cost-benefit analysis that evaluates both the initial investment and long-term savings. Buyers should be encouraged to consider the durability and low maintenance costs associated with aluminum pergolas, which can lead to lower overall expenditures compared to wood or other materials that require frequent repairs or replacements. Suppliers can assist buyers by providing detailed case studies and testimonials that showcase the added value and ROI of aluminum pergolas in various commercial settings. Additionally, offering flexible financing options or bulk purchase discounts can make the investment more attractive. Buyers should also evaluate the potential of aluminum pergolas to enhance property value and increase customer satisfaction, which can translate into increased revenue over time.

Strategic Material Selection Guide for aluminum pergola

When selecting materials for aluminum pergolas, it’s essential to consider various factors that influence performance, durability, and cost. Below is an analysis of four common materials used in conjunction with aluminum pergolas, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to aluminum pergola

What Are the Key Properties of Aluminum in Pergola Construction?

Aluminum is a lightweight, corrosion-resistant metal that offers high strength-to-weight ratios. Its ability to withstand extreme temperatures and pressures makes it suitable for various climates, particularly in regions like the Middle East and Africa, where high temperatures are common. Additionally, aluminum can be treated with finishes that enhance its durability and aesthetic appeal, making it an attractive option for modern outdoor structures.

What Are the Advantages and Disadvantages of Using Aluminum for Pergolas?

Pros:

– Durability: Aluminum is resistant to rust, corrosion, and UV damage, making it ideal for outdoor applications.

– Low Maintenance: Unlike wood, aluminum does not require regular painting or sealing, reducing long-term maintenance costs.

– Design Flexibility: Available in various colors and finishes, aluminum allows for customization to meet aesthetic preferences.

Cons:

– Cost: While aluminum is generally more affordable than some high-end materials, it can still be cost-prohibitive compared to lower-cost alternatives like wood.

– Thermal Conductivity: Aluminum can become hot to the touch in direct sunlight, which may affect comfort levels in warmer climates.

Illustrative image related to aluminum pergola

How Does Aluminum Impact Application in Different Climates?

Aluminum’s corrosion resistance makes it particularly suitable for humid and coastal environments, where other materials might fail. In regions like Saudi Arabia or Nigeria, where heat and humidity are prevalent, aluminum’s ability to withstand these conditions without degrading is a significant advantage. However, buyers should ensure that the aluminum used is of high quality and meets international standards, such as ASTM or DIN, to guarantee performance.

What Should International Buyers Consider When Selecting Aluminum Pergolas?

For B2B buyers in Africa, South America, the Middle East, and Europe, compliance with local building codes and standards is critical. Buyers should verify that the materials used in aluminum pergolas meet regional regulations, ensuring safety and durability. Additionally, preferences for aesthetics and functionality may vary by region, influencing the choice of finishes and designs. Understanding these nuances can help buyers make informed decisions that align with market demands.

Summary Table of Material Selection for Aluminum Pergolas

| Material | Typical Use Case for aluminum pergola | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Residential and commercial outdoor spaces | High corrosion resistance and low maintenance | Higher initial cost compared to wood | Medium |

| Wood | Traditional pergola designs | Aesthetic appeal and natural look | Prone to rot and requires regular maintenance | Low |

| Composite | Eco-friendly options for modern designs | Durable and low maintenance | Can be more expensive than aluminum | High |

| Steel | Heavy-duty structures requiring high strength | Exceptional strength and durability | Susceptible to rust without proper treatment | Medium |

This guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding aluminum pergola materials, ensuring they select the best options for their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum pergola

What Are the Key Stages in the Manufacturing Process of Aluminum Pergolas?

The manufacturing of aluminum pergolas involves several critical stages, each essential for ensuring the final product meets quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to aluminum pergola

How Is Material Prepared for Aluminum Pergolas?

Material preparation begins with selecting high-quality aluminum alloys, which are known for their strength and resistance to corrosion. Suppliers often use 6061 or 6063 aluminum alloys due to their excellent mechanical properties and versatility. The raw aluminum is then cut into specified lengths using precision saws. This step is crucial, as accurate measurements directly affect the structural integrity and aesthetics of the pergola.

What Techniques Are Used in Forming Aluminum Pergolas?

The forming stage typically involves several techniques to shape the aluminum into the desired components. Common methods include extrusion, bending, and stamping.

-

Extrusion: This is the most prevalent method for creating aluminum profiles for pergolas. The aluminum is heated and forced through a die to create continuous lengths of specific cross-sectional shapes, which are then cooled and cut to size.

-

Bending and Stamping: For components that require curves or specific shapes, bending machines and stamping presses are used. These techniques allow for intricate designs while maintaining the structural strength of the aluminum.

How Is Assembly Conducted in Aluminum Pergola Manufacturing?

Once the individual components are formed, the assembly stage commences. This step involves skilled labor to join parts using various techniques such as welding, riveting, or using mechanical fasteners. Each connection is meticulously checked to ensure it meets design specifications and tolerances.

Automated assembly lines are increasingly common, incorporating robotics for precision and efficiency. This not only speeds up production but also enhances consistency across units.

Illustrative image related to aluminum pergola

What Finishing Processes Are Applied to Aluminum Pergolas?

The finishing stage is essential for both aesthetics and durability. Aluminum pergolas are typically anodized or powder-coated to provide a protective layer against environmental factors.

-

Anodizing: This electrochemical process increases corrosion resistance and can add color to the aluminum surface.

-

Powder Coating: In this method, a dry powder is applied electrostatically and cured under heat, creating a hard, protective finish that is available in various colors.

Both methods improve the lifespan of the pergola and reduce maintenance needs, appealing to international buyers looking for long-lasting outdoor solutions.

What Quality Assurance Measures Are Essential for Aluminum Pergolas?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final product adheres to international standards and meets buyer specifications. Key QA measures include compliance with relevant standards, implementation of checkpoints throughout the manufacturing process, and the use of robust testing methods.

Which International Standards Are Relevant for Aluminum Pergolas?

For B2B buyers, understanding applicable international standards is vital. The ISO 9001 standard for quality management systems is widely recognized and ensures that manufacturers maintain quality across all production stages. Additionally, certifications such as CE (European Conformity) and API (American Petroleum Institute) may apply, depending on the intended use of the pergola.

These certifications assure buyers that the products meet safety and environmental requirements, which is particularly important for markets in Africa, South America, the Middle East, and Europe.

Illustrative image related to aluminum pergola

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is typically integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During production, checks are performed at various stages to catch defects early. This can include dimensional checks and visual inspections.

-

Final Quality Control (FQC): Before shipping, a comprehensive inspection is conducted to ensure the finished product meets all specifications and standards.

Implementing these checkpoints helps mitigate risks associated with defects and ensures consistency in product quality.

What Common Testing Methods Are Used for Aluminum Pergolas?

Several testing methods are employed to validate the quality and performance of aluminum pergolas:

-

Mechanical Testing: This includes tensile strength tests, which measure the material’s ability to withstand stress, and impact tests that evaluate toughness.

-

Corrosion Resistance Testing: Salt spray tests are commonly used to assess how well the aluminum withstands corrosive environments, particularly in coastal areas.

-

Dimensional Checks: Precision measuring tools are utilized to ensure all components meet specified dimensions.

These tests are crucial for B2B buyers who require assurance of durability and performance, especially in diverse environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to ensure that their suppliers maintain rigorous quality control standards. Here are effective ways to verify supplier QC:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, processes, and quality control systems directly. This firsthand observation can provide invaluable insights into the supplier’s capabilities.

-

Requesting Quality Reports: Suppliers should provide documentation of their QC processes, including results from any testing conducted. This transparency is essential for building trust.

-

Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing process and final products can provide an unbiased assessment of quality.

-

Certifications Verification: Buyers should verify that the supplier holds relevant certifications (ISO, CE, etc.) and that these certifications are current and applicable to their products.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

Illustrative image related to aluminum pergola

-

Cultural Differences: Understanding the local manufacturing culture can provide insights into the supplier’s approach to quality and customer service.

-

Regulatory Compliance: Different regions may have varying regulations regarding materials and manufacturing processes. Buyers should ensure that suppliers comply with local laws and international standards applicable to their markets.

-

Logistics and Transportation: Consideration should be given to how quality is maintained during transportation, particularly in regions with challenging logistics. Ensuring that packaging and handling procedures are in place can help mitigate damage during transit.

By understanding these aspects of manufacturing and quality assurance, B2B buyers can make informed decisions when sourcing aluminum pergolas, ensuring they invest in products that meet their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum pergola’

In the competitive landscape of outdoor living solutions, sourcing the right aluminum pergola can significantly enhance your business offerings. This guide provides a structured approach to help B2B buyers make informed decisions, ensuring they acquire high-quality products that meet market demands.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the aluminum pergola meets the needs of your target market. Consider factors such as size, design, and functionality, including adjustable roofs or integrated lighting options. Having precise specifications helps streamline the selection process and ensures that the products align with your customers’ expectations.

Step 2: Research Market Trends and Customer Preferences

Understanding current market trends is essential for sourcing aluminum pergolas that will appeal to your customers. Analyze popular designs, materials, and features that are in demand, such as louvered roofs or weather-resistant finishes. Engage with potential customers through surveys or focus groups to gain insights into their preferences, which will inform your sourcing decisions.

Illustrative image related to aluminum pergola

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s vital to conduct thorough evaluations. Request detailed company profiles, case studies, and references from other buyers in your industry or region. Look for suppliers with a proven track record in manufacturing high-quality aluminum pergolas, as this will reduce the risk of sourcing inferior products.

- Check Certifications: Ensure suppliers have necessary certifications, such as ISO or CE marking, to guarantee quality standards.

- Assess Production Capacity: Verify that the supplier can meet your order volume and delivery timelines.

Step 4: Request Samples and Product Specifications

Always request samples of the aluminum pergolas you are considering. This allows you to assess the quality, durability, and aesthetic appeal of the products firsthand. Additionally, obtain detailed product specifications, including material compositions and warranty information, to ensure they meet your quality standards.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers, initiate discussions regarding pricing and terms. Be prepared to negotiate to secure the best possible deal while ensuring that quality is not compromised. Consider factors such as bulk order discounts, shipping costs, and payment terms to optimize your procurement strategy.

Step 6: Verify After-Sales Support and Warranty Options

Reliable after-sales support and warranty options are critical in the B2B space. Ensure that the supplier offers comprehensive customer service and a clear warranty policy that covers defects or damages. This not only protects your investment but also enhances your business reputation by ensuring customer satisfaction.

Step 7: Finalize the Order and Establish a Relationship

After selecting a supplier, finalize your order with clear terms and conditions. Establish a strong relationship with the supplier for ongoing support and future orders. Maintaining open communication will help address any issues promptly and facilitate smoother transactions in the future.

Illustrative image related to aluminum pergola

By following this step-by-step checklist, B2B buyers can navigate the sourcing process for aluminum pergolas more effectively, ensuring they meet market demands and enhance their product offerings.

Comprehensive Cost and Pricing Analysis for aluminum pergola Sourcing

What Are the Key Cost Components for Sourcing Aluminum Pergolas?

When sourcing aluminum pergolas, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: Aluminum, known for its durability and low maintenance, is the primary material. The cost can vary significantly based on the alloy grade and finish (e.g., powder coating or anodizing). High-quality aluminum often comes at a premium but offers better resistance to corrosion and wear.

-

Labor: Labor costs encompass the workforce needed for manufacturing, assembling, and installing the pergolas. Regions with higher labor costs may affect the overall pricing, so consider sourcing from areas with competitive labor rates.

-

Manufacturing Overhead: This includes costs related to the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can minimize these overheads, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom designs or sizes may require specialized tooling, which can increase upfront costs. Understanding the tooling requirements early can help you gauge potential cost implications.

-

Quality Control (QC): Rigorous QC processes ensure that the final product meets industry standards and client expectations. While this adds to the cost, it is essential for maintaining quality and reducing returns or rework.

-

Logistics: Shipping costs can vary based on the geographical distance from the supplier to the buyer, transport mode, and any customs tariffs that may apply. It’s vital to consider these factors, especially for international transactions.

-

Margin: Suppliers typically mark up prices to cover their costs and achieve profitability. Understanding the margin expectations of your suppliers can help in negotiations.

What Influences the Price of Aluminum Pergolas?

Several factors can influence the pricing of aluminum pergolas, particularly in international B2B transactions:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should assess their needs carefully to leverage bulk purchasing advantages.

-

Specifications/Customization: Custom designs or specific features (like louvered roofs) can significantly affect pricing. While customization allows for tailored solutions, it may also lead to higher costs.

-

Materials and Quality Certifications: Products with higher-grade materials or certifications (e.g., ISO) typically command higher prices. Buyers should weigh the benefits of certifications against their budgets.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers may offer better warranties and service, which can justify higher costs.

-

Incoterms: Understanding the terms of shipping and responsibility for costs during transport is crucial. Different Incoterms can affect the final landed cost of the product.

What Are the Best Practices for Negotiating Prices on Aluminum Pergolas?

Negotiation is key to ensuring cost-efficiency in your aluminum pergola sourcing. Here are some actionable tips:

Illustrative image related to aluminum pergola

-

Research Market Prices: Familiarize yourself with market prices to establish a baseline for negotiations. Having data on competitor pricing can empower your position.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the upfront cost but also the long-term costs associated with maintenance and durability. A higher initial investment in quality materials can lead to lower TCO.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable deals.

-

Be Transparent About Your Needs: Clearly communicate your requirements and volume expectations. Suppliers may offer better pricing if they understand your business context.

-

Explore Payment Terms: Negotiating favorable payment terms can improve cash flow. Consider options like partial payments or extended payment plans.

Conclusion

In summary, the cost and pricing analysis for aluminum pergola sourcing involves understanding various components and influencers. By applying effective negotiation strategies and considering the total cost of ownership, B2B buyers can secure favorable deals tailored to their specific needs. Always remember that prices can vary widely based on regional factors and supplier capabilities, so due diligence is essential.

Alternatives Analysis: Comparing aluminum pergola With Other Solutions

When considering outdoor structures for enhancing spaces, aluminum pergolas are a popular choice due to their durability and modern design. However, there are alternative solutions that may also fulfill similar needs. This section will analyze aluminum pergolas in comparison to traditional wooden pergolas and fabric shade structures, providing actionable insights for B2B buyers looking to make informed decisions.

| Comparison Aspect | Aluminum Pergola | Traditional Wooden Pergola | Fabric Shade Structure |

|---|---|---|---|

| Performance | High durability; adjustable louvers for optimal shade control | Moderate durability; fixed structure limits flexibility | Varies by fabric; generally offers good UV protection |

| Cost | Higher initial investment ($2,000 – $10,000) | Generally lower cost ($1,000 – $5,000) | Varies widely ($500 – $3,000) depending on size and materials |

| Ease of Implementation | Requires professional installation; suitable for various environments | Easier DIY installation; requires treatment for weather resistance | Simple to install; can be temporary or permanent |

| Maintenance | Low maintenance; periodic cleaning required | High maintenance; requires regular treatment against rot | Minimal maintenance; replace fabric as needed |

| Best Use Case | Commercial and high-end residential spaces seeking modern aesthetics | Residential areas looking for traditional charm | Temporary shade for events, patios, or outdoor gatherings |

What Are the Advantages and Disadvantages of Traditional Wooden Pergolas Compared to Aluminum Pergolas?

Traditional wooden pergolas bring a rustic charm that appeals to many homeowners. They are generally more affordable and easier to install for DIY enthusiasts. However, they often require substantial maintenance to prevent rot and degradation from exposure to the elements. Unlike aluminum pergolas, which offer adjustable louvers for shade control, wooden pergolas typically feature a fixed design that limits versatility in sun management.

Illustrative image related to aluminum pergola

How Do Fabric Shade Structures Compare to Aluminum Pergolas?

Fabric shade structures are versatile and can be a cost-effective solution for providing shade in outdoor spaces. They are often lightweight and can be easily installed, making them suitable for temporary setups or events. However, the durability of fabric structures can be a concern, as they are susceptible to tearing and may require replacement over time. While they provide good UV protection, they lack the aesthetic appeal and sturdiness of aluminum pergolas, which can enhance property value and withstand harsh weather conditions.

How Can B2B Buyers Choose the Right Solution for Their Outdoor Needs?

Selecting the right outdoor structure depends on various factors such as budget, desired aesthetics, and specific use cases. For businesses or individuals looking for a long-term investment that combines style and functionality, aluminum pergolas may be the best choice. Conversely, those seeking a more budget-friendly option or a temporary solution might find traditional wooden pergolas or fabric shade structures more suitable. Ultimately, understanding the unique requirements of your outdoor space will guide you in choosing the solution that aligns with your operational goals and enhances the overall outdoor experience.

Essential Technical Properties and Trade Terminology for aluminum pergola

What Are the Key Technical Properties of Aluminum Pergolas?

When sourcing aluminum pergolas, understanding their technical properties is essential for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

-

Material Grade

Aluminum pergolas are typically made from various grades of aluminum, such as 6061 or 6063. The grade indicates the alloy’s strength, durability, and corrosion resistance. For outdoor applications, a higher grade, like 6061, is preferred due to its enhanced mechanical properties and weather resistance. Selecting the right material grade is crucial for ensuring longevity and minimizing maintenance costs. -

Thickness and Profile

The thickness of aluminum components, often measured in millimeters, affects the pergola’s structural integrity. Common thicknesses range from 1.5 mm to 3 mm. A thicker profile enhances durability and resistance to bending or warping under stress. Buyers should assess the expected load and environmental conditions to choose an appropriate thickness that will withstand local weather conditions. -

Finish and Coating

Aluminum pergolas often come with different finishes, such as powder coating or anodizing. Powder coating provides a durable, UV-resistant layer that protects against fading and corrosion, while anodizing enhances surface hardness and resistance to scratches. Understanding the finishing process is essential for evaluating the pergola’s aesthetic appeal and maintenance requirements. -

Load Capacity

This specification indicates how much weight the pergola can support, which is vital for applications that may involve hanging lights, plants, or other structures. Load capacity is determined by the design and material strength. Buyers should inquire about load testing to ensure that the pergola meets safety standards and can accommodate their specific needs. -

Warranty Terms

Warranties for aluminum pergolas typically cover defects in materials and workmanship. A standard warranty period ranges from 5 to 15 years. Understanding the warranty terms helps buyers assess the manufacturer’s confidence in their product and offers protection against premature failure. -

Assembly Requirements

Some aluminum pergolas are available as pre-assembled units, while others require installation. Buyers should evaluate the ease of assembly, the need for specialized tools, and whether professional installation is recommended. This consideration impacts project timelines and labor costs.

What Are Common Trade Terms Related to Aluminum Pergolas?

Familiarity with industry jargon can streamline procurement processes and facilitate effective communication. Here are several common terms used in the aluminum pergola market:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of aluminum pergolas, understanding OEM relationships can help buyers identify quality products and ensure they are sourcing from reputable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest order quantity a supplier will accept. This is critical for B2B buyers as it affects inventory management and pricing strategies. Knowing the MOQ can help buyers plan their purchasing strategy, especially when entering new markets or launching new products. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to request price quotes from suppliers. It typically includes specifications, quantities, and delivery timelines. Utilizing RFQs can streamline the procurement process and ensure that all vendors provide comparable pricing and terms. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B transactions involving international shipping, as they clarify the costs and risks associated with the delivery of aluminum pergolas. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This includes production, shipping, and delivery times. Buyers should consider lead time when planning projects to ensure timely completion. -

Customization Options

This term refers to the ability to modify standard products to meet specific client needs, such as size, color, or design features. Understanding customization options can help buyers differentiate their offerings in competitive markets and meet unique customer demands.

By grasping these technical properties and trade terms, B2B buyers can navigate the aluminum pergola market more effectively, ensuring they make informed decisions that align with their business objectives.

Illustrative image related to aluminum pergola

Navigating Market Dynamics and Sourcing Trends in the aluminum pergola Sector

What Are the Current Market Dynamics and Key Trends in the Aluminum Pergola Sector?

The aluminum pergola market is experiencing significant growth, driven by increasing consumer interest in outdoor living spaces and the demand for customizable outdoor structures. Key trends include the rise of louvered pergolas, which offer adjustable roofs for optimal sunlight control and ventilation, appealing to modern aesthetics and functionality. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking these versatile solutions as they enhance outdoor experiences, making them ideal for both residential and commercial applications.

Technological advancements are also shaping sourcing strategies in this sector. Innovations such as integrated lighting systems and smart home compatibility are becoming popular, providing additional value to end-users. Moreover, the trend towards e-commerce platforms for B2B transactions is streamlining procurement processes, allowing buyers to compare products, prices, and specifications efficiently.

Global sourcing dynamics are influenced by factors such as raw material availability, shipping logistics, and trade regulations. For instance, buyers in the Middle East may face different challenges than those in Europe due to varying import tariffs and local manufacturing capabilities. Understanding these dynamics is crucial for international buyers to ensure timely and cost-effective procurement.

Illustrative image related to aluminum pergola

How Does Sustainability Influence the Sourcing of Aluminum Pergolas?

Sustainability is a pivotal consideration in the aluminum pergola market. The production and disposal of aluminum can have significant environmental impacts, making it essential for B2B buyers to prioritize ethical sourcing practices. Manufacturers that utilize recycled aluminum not only reduce their carbon footprint but also cater to the growing consumer demand for sustainable products.

Furthermore, buyers should look for suppliers that hold environmental certifications, such as LEED (Leadership in Energy and Environmental Design) or ISO 14001, indicating adherence to rigorous environmental management standards. These certifications are increasingly becoming prerequisites for procurement, especially in markets focused on sustainability initiatives, such as Europe.

Ethical supply chains are also crucial. Engaging with manufacturers that demonstrate transparency in their sourcing processes helps buyers mitigate risks associated with labor practices and environmental compliance. This commitment to sustainability not only enhances brand reputation but can also lead to long-term cost savings through improved efficiency and waste reduction.

What Is the Brief Evolution of Aluminum Pergolas in the B2B Market?

The evolution of aluminum pergolas has been marked by a shift from traditional wooden structures to modern aluminum designs, reflecting changing consumer preferences and technological advancements. Initially, pergolas were primarily constructed from wood, which, while aesthetically pleasing, presented challenges related to maintenance, durability, and susceptibility to weather conditions.

As architectural styles evolved and the demand for low-maintenance outdoor solutions grew, aluminum emerged as a preferred material due to its lightweight, corrosion-resistant properties. This transition has been particularly significant in regions with harsh climates, where aluminum’s durability offers a clear advantage.

Illustrative image related to aluminum pergola

Today, the market has expanded to include a variety of customizable options, including louvered roofs and integrated lighting systems, catering to both residential and commercial sectors. This evolution not only reflects changing consumer needs but also highlights the industry’s adaptability in meeting the demands of a diverse global market.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum pergola

-

How do I choose the right aluminum pergola for my business needs?

Selecting the right aluminum pergola involves assessing your specific requirements such as size, design, and functionality. Consider the space available and the intended use—whether for dining, relaxation, or events. It’s also vital to evaluate the climate conditions in your region; for instance, adjustable louvered roofs are ideal for areas with fluctuating weather as they provide both shade and ventilation. Ensure to compare various suppliers to find one that offers durable materials and customizable options to suit your aesthetic preferences. -

What are the advantages of aluminum pergolas over traditional materials?

Aluminum pergolas offer numerous advantages compared to traditional wood or steel options. They are lightweight yet robust, resistant to rust and corrosion, and require minimal maintenance—only needing occasional cleaning. Unlike wood, aluminum does not warp or crack over time, making it a more sustainable choice for outdoor structures. Additionally, the modern design possibilities with aluminum, such as adjustable louvered roofs, allow for enhanced functionality and aesthetics tailored to contemporary architectural styles. -

What customization options should I consider when sourcing aluminum pergolas?

Customization can significantly enhance the appeal of aluminum pergolas for your clients. Look for suppliers that offer options such as color finishes, size variations, and roof styles—like fixed or adjustable louvered roofs. Additional features like integrated lighting, curtains, or heating elements can also be tailored to meet specific needs. Collaborating closely with your supplier to understand available customization options can help you deliver unique products that stand out in the market. -

What is the typical minimum order quantity (MOQ) for aluminum pergolas?

Minimum order quantities can vary significantly among suppliers, often influenced by production capabilities and shipping logistics. Generally, MOQs for aluminum pergolas range from 5 to 50 units, depending on the size and complexity of the design. When sourcing, inquire about the supplier’s flexibility regarding MOQs, especially if you are testing the market or have specific project requirements. Establishing a good relationship with your supplier may also lead to more favorable terms. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common arrangements include upfront deposits (typically 30-50%) with the balance due upon delivery or before shipment. Some suppliers may offer credit terms or payment through letters of credit, particularly for larger orders. It’s crucial to clarify payment methods, currencies accepted, and any additional fees upfront to avoid misunderstandings later in the transaction process. -

How can I ensure quality assurance (QA) for aluminum pergolas?

Ensuring quality assurance involves several steps. Start by vetting suppliers based on their reputation, experience, and certifications. Request samples to assess material quality and craftsmanship before committing to a large order. Additionally, consider implementing a QA process that includes inspections at various stages of production and before shipment. Establishing clear quality standards and communicating them to your supplier can help maintain consistency and reliability in your products. -

What logistics considerations should I keep in mind when importing aluminum pergolas?

Logistics play a crucial role in the successful importation of aluminum pergolas. Consider factors such as shipping methods, lead times, and customs regulations in your country. Work closely with your supplier to understand the packaging requirements to prevent damage during transit. Additionally, consider partnering with a reliable freight forwarder who can handle customs clearance and provide guidance on import duties and taxes to streamline the process. -

What are the common challenges when sourcing aluminum pergolas internationally?

Common challenges include navigating varying regulations, tariffs, and customs procedures that can delay delivery and increase costs. Language barriers may also complicate communication with suppliers. To mitigate these challenges, conduct thorough research on potential suppliers, engage in clear communication, and establish a strong contract that outlines expectations and responsibilities. Building relationships with reliable partners can also help ease the sourcing process and ensure better outcomes.

Top 6 Aluminum Pergola Manufacturers & Suppliers List

1. Mirador – Mirador 111DA Aluminum Pergola

Domain: miradoroutdoor.com

Registered: 2023 (2 years)

Introduction: Mirador 111DA Aluminum Pergola: 10’x10′ – $2,399.00, 10’x13′ – $2,999.00, 10’x20′ – $4,399.00, 12’x12′ – $3,699.00, 12’x24′ – $6,999.00, 24’x24′ (L) Shape – $9,999.00. Features: modern outdoor living space, adjustable louvered roof for sunlight and ventilation control, available in Charcoal and White colors. Mirador 111S Takasho Wood Grain Texture Pergola: 10’x10′ Cherry Oak – $2,099.00, 10’x13′ C…

2. Purple Leaf – Louvered Pergola Kits

Domain: purpleleafshop.com

Registered: 2019 (6 years)

Introduction: Louvered Pergola Kits, Adjustable Outdoor Shade, Black Friday Sale, Extra 15% Off, Available Sizes: Small (10′ x 10′, 10′ x 12′, 10′ x 13′, 10′ x 14′, 10′ x 16′, 11′ x 13′, 11′ x 14′, 11′ x 15′), Big (10′ x 18′, 11′ x 18′, 11′ x 21′, 11′ x 23′, 11′ x 28′, 12′ x 12′, 12′ x 14′, 12′ x 16′, 12′ x 18′, 12′ x 20′, 12′ x 24′, 13′ x 15′, 13′ x 20′, 13′ x 25′, 13′ x 30′, 14′ x 20′, 14′ x 24′), Available C…

3. Paragon Outdoor – Grand Tuscan Louvered Pergola

Domain: paragon-outdoor.com

Registered: 2017 (8 years)

Introduction: { “name”: “Grand Tuscan Louvered Pergola”, “brand”: “Paragon Outdoor”, “model”: “PRGRT-1012GY”, “regular_price”: “$2,999.99”, “sale_price”: “$2,399.99”, “discount”: “20% OFF”, “sizes”: [“10′ x 12′”, “12′ x 14′”, “12′ x 20′”], “size_prices”: { “10′ x 12′”: “$2,399.99”, “12′ x 14′”: “$3,359.99”, “12′ x 20′”: “$4,319.99” }, “frame_material”: “Aluminum”, “roof_material”: “Steel”, “roof_style”: “Louver…

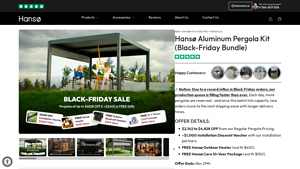

4. Hansø Home – Aluminum Pergola Kits

Domain: hansohome.com

Registered: 2022 (3 years)

Introduction: Aluminum Pergola Kit by Hansø Home

– Models: Pro+ Pergola Kit, Master+ Pergola Kit, Electric Retractable Awning

– Pro+ Pergola:

– Windproof: 72 – 120 MPH

– Snow/Roof Load: Up to 25 PSF

– Material: T5 High-Grade Aluminum

– Lifespan: 30+ years

– Features: Modern design, all-season ready

– Master+ Pergola:

– Windproof: 165 MPH

– Snow/Roof Load: Up to 62 PSF

– Material: T6 Ultra-Streng…

5. The Luxury Pergola – Custom Louvered Pergola

Domain: theluxurypergola.com

Registered: 2022 (3 years)

Introduction: Custom Louvered Pergola | Adjustable Aluminum Pergola Kit | The Luxury Pergola

– Price: From $10,723.71

– Made in USA: Every Luxury Pergola is manufactured in the United States.

– Warranty: Lifetime transferable warranty included.

– Rating: The highest rated pergola kit in the world.

– Pricing Structure: Direct from manufacturer pricing, no middleman markup.

– Aluminum Grade: Aircraft-Grade 6063-T…

6. BON Pergola – Modern Motorized Pergola Kits

Domain: bonpergola.com

Registered: 2019 (6 years)

Introduction: Modern Motorized Pergola Kits from BON Pergola include various models such as the Villa Pergola, Weatherproof Pergola, Grand Retractable Pergola, and Starry Pergola. Key features include:

– Motorized options with LED lighting

– Weather resistance with wind ratings of 80-120 mph and snow ratings of 15-63 psf

– Custom sizes available with maximum spans of 13-23 feet

– Easy assembly in 4-6 hours …

Strategic Sourcing Conclusion and Outlook for aluminum pergola

How Can Strategic Sourcing Enhance Your Aluminum Pergola Procurement?

In conclusion, the strategic sourcing of aluminum pergolas presents a compelling opportunity for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Key takeaways emphasize the importance of leveraging innovative designs, such as adjustable louvered roofs, which offer enhanced versatility and comfort for outdoor spaces. The durability and low maintenance requirements of aluminum structures make them an attractive choice compared to traditional materials, particularly in climates prone to adverse weather conditions.

Investing in aluminum pergolas not only elevates outdoor living experiences but also adds significant value to properties. By prioritizing strategic sourcing partnerships with reliable manufacturers, buyers can ensure they access high-quality products that meet evolving consumer demands.

Looking ahead, the market for aluminum pergolas is poised for growth, driven by increasing outdoor living trends and a rising emphasis on sustainable building materials. We encourage international buyers to explore these opportunities, engage with reputable suppliers, and take proactive steps toward enhancing their product offerings in this thriving sector. The future of outdoor living is here—embrace it with strategic sourcing for aluminum pergolas.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to aluminum pergola