Introduction: Navigating the Global Market for 10×12 pergola

In today’s competitive landscape, sourcing the right 10×12 pergola can be a daunting task for international B2B buyers. As the demand for outdoor living solutions grows, businesses must navigate a complex marketplace filled with diverse materials, designs, and functionalities. This guide is designed to equip buyers from Africa, South America, the Middle East, and Europe, including markets like Vietnam and Brazil, with the essential insights needed to make informed purchasing decisions.

From understanding the various types of pergolas—such as louvered, retractable, and traditional wooden structures—to exploring their applications in residential and commercial settings, this comprehensive resource covers all bases. We delve into key factors such as supplier vetting, ensuring quality and reliability, as well as cost considerations that can impact your bottom line.

By addressing challenges like material selection, design adaptability, and climate suitability, this guide empowers businesses to choose the right pergola that meets both aesthetic and functional requirements. With actionable insights and practical advice, buyers will be better positioned to enhance their outdoor spaces, ultimately driving customer satisfaction and business growth.

Table Of Contents

- Top 6 10X12 Pergola Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 10×12 pergola

- Understanding 10×12 pergola Types and Variations

- Key Industrial Applications of 10×12 pergola

- 3 Common User Pain Points for ’10×12 pergola’ & Their Solutions

- Strategic Material Selection Guide for 10×12 pergola

- In-depth Look: Manufacturing Processes and Quality Assurance for 10×12 pergola

- Practical Sourcing Guide: A Step-by-Step Checklist for ’10×12 pergola’

- Comprehensive Cost and Pricing Analysis for 10×12 pergola Sourcing

- Alternatives Analysis: Comparing 10×12 pergola With Other Solutions

- Essential Technical Properties and Trade Terminology for 10×12 pergola

- Navigating Market Dynamics and Sourcing Trends in the 10×12 pergola Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 10×12 pergola

- Strategic Sourcing Conclusion and Outlook for 10×12 pergola

- Important Disclaimer & Terms of Use

Understanding 10×12 pergola Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Louvered Pergola | Adjustable roof panels for sun and rain control | Outdoor dining areas, commercial patios | Pros: Versatile weather control; modern aesthetics. Cons: Higher cost; more complex installation. |

| Retractable Canopy Pergola | Flexible canopy that can be extended or retracted | Event spaces, temporary setups | Pros: Customizable shade; easy to store. Cons: Mechanism can wear over time; limited structural support. |

| Wooden Pergola | Traditional design, typically made from cedar or pressure-treated wood | Residential backyards, landscaping projects | Pros: Natural aesthetics; durable. Cons: Requires maintenance; susceptible to rot without treatment. |

| Aluminum Pergola | Lightweight, rust-resistant, and often powder-coated | Commercial spaces, poolside areas | Pros: Low maintenance; modern look. Cons: Can be less sturdy in extreme weather; higher initial cost. |

| Hybrid Pergola | Combination of materials (e.g., wood and metal) | Versatile applications in both residential and commercial settings | Pros: Unique design; customizable. Cons: May require more complex installation; potential for higher costs. |

What are the Characteristics of Louvered Pergolas?

Louvered pergolas are designed with adjustable roof panels that can be opened or closed, allowing for optimal control over sunlight and rain. This feature makes them ideal for outdoor dining areas and commercial patios, where versatility is crucial. When considering a louvered pergola for B2B applications, buyers should evaluate the mechanism’s durability and ease of operation, as well as the aesthetic appeal that can enhance the outdoor ambiance.

How Do Retractable Canopy Pergolas Work?

Retractable canopy pergolas feature a flexible canopy that can be easily extended or retracted, providing customizable shade options. This makes them suitable for event spaces or temporary setups where adaptability is essential. B2B buyers should consider the ease of operation and the durability of the canopy fabric, as well as the overall design that can complement various outdoor settings.

Illustrative image related to 10×12 pergola

What Are the Advantages of Wooden Pergolas?

Wooden pergolas offer a classic and natural look, often constructed from durable materials like cedar or pressure-treated wood. They are commonly used in residential backyards and landscaping projects. For B2B buyers, the aesthetic appeal and durability are significant advantages; however, they must also factor in the maintenance requirements to prevent decay and ensure longevity.

Why Choose Aluminum Pergolas?

Aluminum pergolas are lightweight and rust-resistant, often featuring a powder-coated finish for added protection. They are well-suited for commercial spaces and poolside areas due to their low maintenance needs and modern appearance. Buyers should assess the pergola’s structural integrity, especially in regions prone to extreme weather, as well as the initial investment compared to other materials.

What Makes Hybrid Pergolas Unique?

Hybrid pergolas combine different materials, such as wood and metal, to create a unique design that suits various applications. This versatility makes them attractive for both residential and commercial settings. B2B purchasers should consider the customization options available and the potential complexity of installation, as well as the balance between aesthetic appeal and functional durability.

Key Industrial Applications of 10×12 pergola

| Industry/Sector | Specific Application of 10×12 Pergola | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Outdoor dining areas for restaurants and cafes | Enhances guest experience, increases seating capacity | Weather resistance, aesthetic appeal, ease of installation |

| Landscaping & Gardening | Shade structures in public parks or botanical gardens | Provides shelter for visitors, promotes plant growth | Durability, design compatibility, maintenance requirements |

| Real Estate Development | Outdoor living spaces in residential projects | Adds value to properties, attracts buyers | Customization options, compliance with local regulations |

| Event Planning | Temporary installations for weddings and events | Creates attractive venues, enhances outdoor events | Portability, ease of assembly, rental options |

| Retail | Display areas in outdoor markets or shopping centers | Increases foot traffic, creates inviting shopping spaces | Structural integrity, branding opportunities, weatherproofing |

How is a 10×12 Pergola Applied in the Hospitality Industry?

In the hospitality sector, a 10×12 pergola serves as an attractive outdoor dining area for restaurants and cafes. By providing shade and shelter, it enhances the guest experience, allowing patrons to enjoy meals outdoors while being protected from the elements. This structure can increase seating capacity, especially during peak seasons. For international buyers, sourcing pergolas that are weather-resistant and aesthetically appealing is crucial, as these elements can significantly influence customer satisfaction and retention.

Illustrative image related to 10×12 pergola

What Role Does a 10×12 Pergola Play in Landscaping and Gardening?

In landscaping and gardening, a 10×12 pergola is often used as a shade structure in public parks or botanical gardens. This application not only provides shelter for visitors but also creates a microclimate conducive to plant growth. It can serve as a focal point in garden designs, attracting visitors and encouraging longer stays. Buyers in this sector should consider the durability of materials and design compatibility with existing landscapes to ensure seamless integration into their projects.

How Can Real Estate Developers Utilize a 10×12 Pergola?

Real estate developers frequently incorporate 10×12 pergolas in outdoor living spaces for residential projects. These structures enhance the aesthetic appeal of properties, making them more attractive to potential buyers. A well-designed pergola can add significant value to a home by creating a functional and stylish outdoor area. Buyers should focus on customization options and ensure compliance with local building regulations to maximize the return on investment.

Why is a 10×12 Pergola Essential for Event Planning?

In the event planning industry, a 10×12 pergola is often utilized for temporary installations at weddings and outdoor events. It creates an inviting venue that enhances the overall experience for guests. The ease of assembly and portability of these structures makes them ideal for various events. Event planners should consider sourcing pergolas that are easy to set up and dismantle, as well as those that can withstand various weather conditions to ensure a successful event.

How Do Retail Businesses Benefit from a 10×12 Pergola?

Retail businesses can leverage 10×12 pergolas to create display areas in outdoor markets or shopping centers. These structures not only increase foot traffic but also create inviting shopping spaces that encourage customers to linger. When sourcing pergolas for retail applications, businesses should prioritize structural integrity and weatherproofing, as well as opportunities for branding and customization, to enhance their marketing efforts and customer engagement.

Illustrative image related to 10×12 pergola

3 Common User Pain Points for ’10×12 pergola’ & Their Solutions

Scenario 1: Complications with Weather Resistance for Pergolas in Diverse Climates

The Problem: B2B buyers often struggle with selecting pergolas that can withstand varying weather conditions. For instance, businesses in regions with heavy rainfall or extreme heat need structures that are not only aesthetically pleasing but also durable and weather-resistant. Buyers may find themselves overwhelmed by the variety of materials and designs available, leading to uncertainty about the right choice for their climate. Additionally, concerns about rust, fading, or structural integrity over time can arise, particularly for those unfamiliar with the nuances of pergola materials.

The Solution: To address these challenges, it’s essential for buyers to prioritize materials known for their durability and weather resistance. For instance, aluminum pergolas, such as those offered by brands like Purple Leaf, provide excellent resistance to rust and corrosion, making them ideal for humid or rainy climates. When sourcing, look for models with adjustable roofs that can be closed during inclement weather. Additionally, consider options with integrated drainage systems that channel rainwater away, preventing accumulation and potential damage. For regions experiencing high temperatures, pergolas with UV-resistant finishes or retractable canopies can provide much-needed shade and help maintain the structure’s integrity over time. Partnering with suppliers who offer detailed product specifications and warranties can further ensure that you are making a reliable investment.

Scenario 2: Installation Challenges and Assembly Time for Pergola Kits

The Problem: Many B2B buyers encounter issues with the installation of pergola kits, which can lead to delays and increased labor costs. Businesses that plan to use pergolas for outdoor dining or event spaces often require a quick setup to meet seasonal demands. However, complicated assembly processes can deter teams from efficiently completing installations, leading to frustration and potential financial losses. Additionally, inadequate instructions can result in improper assembly, compromising the structure’s safety and longevity.

The Solution: To mitigate installation challenges, buyers should select pergolas that emphasize ease of assembly. Look for products that come with pre-cut and pre-drilled components, along with comprehensive installation manuals or instructional videos, as seen with brands like Mirador and Backyard Discovery. Investing in pergolas that include all necessary hardware and tools for assembly can streamline the installation process significantly. Moreover, consider enlisting professional installation services offered by some manufacturers, which can save time and ensure the structure is built to code. Creating a timeline and schedule for installation, along with a checklist of required tools and steps, can further enhance efficiency and reduce downtime.

Scenario 3: Balancing Cost and Quality When Purchasing Pergolas

The Problem: B2B buyers often face the challenge of balancing cost and quality when selecting a 10×12 pergola. With a wide range of options available, it can be tempting to choose lower-priced models that may compromise on durability or features. This decision can lead to higher long-term costs due to maintenance, repairs, or replacement. Businesses need to ensure that they are investing in pergolas that not only fit their budget but also meet their aesthetic and functional requirements.

Illustrative image related to 10×12 pergola

The Solution: To make informed purchasing decisions, buyers should conduct thorough market research and compare the features and warranties of different pergolas. Look for brands that offer a good balance between price and quality, ensuring that the materials used are durable, such as cedar wood or high-grade aluminum, and that they come with a substantial warranty. Engage with suppliers who provide transparent pricing structures and can explain the value of their products, including benefits like enhanced weather resistance or energy efficiency. Additionally, consider the long-term return on investment (ROI) of each option. Investing in a higher-quality pergola that meets specific business needs can lead to reduced maintenance costs and increased customer satisfaction in the long run, enhancing the overall value of the purchase.

Strategic Material Selection Guide for 10×12 pergola

What Are the Key Properties of Common Materials for 10×12 Pergolas?

When selecting materials for a 10×12 pergola, understanding the properties and performance characteristics of various materials is crucial for B2B buyers. Here, we analyze four common materials: wood, aluminum, steel, and vinyl.

How Does Wood Perform as a Material for Pergolas?

Wood, particularly cedar and redwood, is a traditional choice for pergolas. Its natural beauty and strength make it appealing. Key properties include excellent tensile strength and natural resistance to decay and insects, especially in cedar. However, wood is susceptible to warping, cracking, and requires regular maintenance, such as sealing and staining, to prolong its lifespan.

Pros: Wood is aesthetically pleasing and can be easily customized. It is also relatively low in cost compared to metal options.

Illustrative image related to 10×12 pergola

Cons: Wood requires ongoing maintenance, is prone to weather damage, and may not be suitable for humid or extremely dry climates without proper treatment.

For international buyers, compliance with local building codes and standards is essential. In regions like Africa and South America, where humidity can be high, selecting treated wood can mitigate decay risks.

What Advantages Does Aluminum Offer for Pergolas?

Aluminum is increasingly popular due to its lightweight nature and resistance to corrosion. It has a high strength-to-weight ratio, making it suitable for various climates. Aluminum pergolas can be powder-coated for additional weather resistance and aesthetic appeal.

Illustrative image related to 10×12 pergola

Pros: Aluminum is low maintenance and does not rust, making it ideal for coastal areas. It can also be manufactured in various colors and styles.

Cons: The initial cost can be higher than wood, and while it is durable, it may not have the same aesthetic warmth as natural wood.

B2B buyers should consider local preferences for materials. In Europe, for instance, aluminum is favored for its modern look and durability, while in regions like the Middle East, its resistance to heat and corrosion is a significant advantage.

Illustrative image related to 10×12 pergola

Why Choose Steel for a 10×12 Pergola?

Steel, particularly galvanized or powder-coated steel, provides exceptional strength and durability. It can withstand extreme weather conditions, making it suitable for areas with high winds or heavy snowfall. Steel also allows for more intricate designs and larger spans without the need for additional support.

Pros: Steel is incredibly strong and can be engineered to meet specific load requirements, making it ideal for commercial applications.

Cons: It is heavier than aluminum and wood, which can complicate installation. Additionally, if not properly treated, steel can rust over time.

For international buyers, compliance with structural standards is critical. In regions with stringent building codes, such as parts of Europe, steel structures must meet specific safety and design criteria.

Illustrative image related to 10×12 pergola

What Are the Benefits of Using Vinyl for Pergolas?

Vinyl is a synthetic material that offers a maintenance-free solution. It is resistant to rot, insects, and fading, making it a durable option for outdoor use. Vinyl pergolas can mimic the look of wood without the associated upkeep.

Pros: Vinyl is easy to clean and does not require painting or staining. It is also lightweight and easy to install.

Cons: The initial cost can be higher than wood, and it may not have the same structural integrity as metal options.

For B2B buyers, vinyl is gaining traction in markets where low maintenance is a priority. However, it is essential to verify that the vinyl meets local regulations, especially in regions with extreme temperatures.

Illustrative image related to 10×12 pergola

Summary Table of Material Selection for 10×12 Pergolas

| Material | Typical Use Case for 10×12 pergola | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Residential gardens and patios | Natural aesthetic appeal | Requires regular maintenance | Low |

| Aluminum | Modern outdoor spaces and commercial applications | Corrosion-resistant and low maintenance | Higher initial cost | Medium |

| Steel | High-load and commercial structures | Exceptional strength and durability | Heavier and potential rusting | High |

| Vinyl | Low-maintenance residential options | Maintenance-free and easy to clean | May lack structural integrity | Medium |

This strategic material selection guide provides actionable insights for B2B buyers, ensuring they choose the most suitable materials for their 10×12 pergola projects based on performance, cost, and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for 10×12 pergola

What Are the Key Stages in the Manufacturing Process of a 10×12 Pergola?

Manufacturing a 10×12 pergola involves a series of well-defined stages, ensuring that the final product meets both aesthetic and functional requirements. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality materials, which can include aluminum, steel, or wood, depending on the design and intended use of the pergola. For instance, aluminum is favored for its durability and low maintenance, while cedar wood is preferred for its natural resistance to decay and aesthetic appeal. The materials undergo an initial inspection to ensure they meet specified standards, such as moisture content for wood or alloy composition for metals.

-

Forming: This stage involves shaping the raw materials into the desired components. Techniques such as extrusion for aluminum, cutting, and machining for wood or metal are commonly employed. Advanced CNC (Computer Numerical Control) machines are often used to ensure precision in the cutting and shaping process, minimizing waste and enhancing the quality of each component.

-

Assembly: Once the components are formed, they are assembled into the final pergola structure. This may involve welding, bolting, or using specialized fasteners that ensure the structural integrity of the pergola. Assembly is typically conducted in a controlled environment to prevent damage to the materials and to facilitate quality checks throughout the process.

-

Finishing: The final stage involves applying protective coatings or treatments to enhance durability and aesthetics. For metal pergolas, powder coating is a common technique that provides a tough, weather-resistant finish. Wood pergolas may be stained or treated with sealants to protect against moisture and UV damage. This stage often includes additional quality checks to confirm that the finish meets both aesthetic and performance standards.

How Is Quality Assurance Implemented in Pergola Manufacturing?

Quality assurance (QA) in pergola manufacturing is critical for ensuring that the final product meets international standards and customer expectations. A robust QA process typically includes adherence to international standards such as ISO 9001, as well as industry-specific certifications like CE marking for products sold in Europe or API standards for materials used in construction.

Illustrative image related to 10×12 pergola

-

What Are the Key Quality Checkpoints?

– Incoming Quality Control (IQC): This is the first checkpoint where raw materials are inspected upon arrival. This includes checking for compliance with specifications, such as dimensions, strength, and finish.

– In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to ensure that each stage meets predefined quality criteria. This includes monitoring machinery performance and the quality of formed components.

– Final Quality Control (FQC): Before shipping, each pergola undergoes a final inspection to verify that it meets all design specifications and quality standards. This includes checking the structural integrity, finish quality, and overall aesthetic appeal. -

What Testing Methods Are Commonly Used?

– Mechanical Testing: This may include tensile strength tests for metal components or load-bearing tests for the entire structure.

– Environmental Testing: Pergolas, especially those made from wood, may undergo accelerated aging tests to assess resistance to moisture, UV light, and temperature fluctuations.

– Functional Testing: For models with adjustable features (like louvered roofs), functional tests ensure that these mechanisms operate smoothly and reliably.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are some actionable steps buyers can take:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This can be done through on-site visits or by requesting detailed audit reports.

-

Request Quality Assurance Documentation: Buyers should ask for certificates of compliance with international standards (like ISO 9001) and any relevant industry certifications. This documentation can serve as proof of the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an extra layer of assurance. These independent entities can conduct quality checks at various stages of the manufacturing process, ensuring that the products meet the required specifications before shipment.

-

Review Warranty and Return Policies: Understanding a supplier’s warranty and return policies can provide additional confidence in the quality of the products. A robust warranty often indicates a manufacturer’s confidence in their product quality.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific nuances in quality control that may vary by region. For instance:

- Cultural Differences: Different regions may have varying expectations regarding quality and service. Understanding these differences can help in establishing effective communication and expectations with suppliers.

- Regulatory Compliance: Different countries have distinct regulatory requirements for construction materials. Buyers must ensure that suppliers comply with these regulations to avoid legal issues.

- Logistical Considerations: International shipping can affect product integrity. Buyers should inquire about packaging standards and handling procedures to ensure that products arrive in optimal condition.

In summary, understanding the manufacturing processes and quality assurance practices for 10×12 pergolas is crucial for B2B buyers. By focusing on quality checkpoints, testing methods, and verification strategies, buyers can make informed decisions that align with their business goals and regional requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’10×12 pergola’

To assist B2B buyers in successfully procuring a 10×12 pergola, this practical sourcing guide provides a structured checklist. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and meets your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your pergola. Consider factors such as materials (aluminum, wood, or composite), design features (louvered roofs, retractable canopies), and durability standards (wind and snow load ratings). This step helps in aligning your needs with suppliers’ offerings and ensures you get a product that meets local climate and aesthetic requirements.

Step 2: Conduct Market Research

Invest time in researching the market to identify potential suppliers. Utilize online platforms, industry forums, and trade shows to gather information about leading manufacturers and their product ranges. Pay attention to customer reviews and ratings to gauge the reliability and quality of their offerings. This comprehensive understanding will aid in selecting suppliers that fit your requirements.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record of delivering quality products, as well as those who offer comprehensive warranties and customer support.

- Check Certifications: Ensure that the suppliers adhere to industry standards and possess relevant certifications, which can indicate their commitment to quality and safety.

- Assess Financial Stability: Evaluate the financial health of potential suppliers to ensure they can fulfill your order without risk of disruption.

Step 4: Review Shipping and Delivery Options

Understanding the logistics involved in shipping and delivery is essential for timely procurement. Inquire about lead times, shipping costs, and delivery methods. Some suppliers may offer free shipping or expedited options, which can be advantageous depending on your project timelines.

Illustrative image related to 10×12 pergola

- International Shipping Capabilities: Given your target regions, ensure the supplier has experience in international shipping and can handle customs clearance efficiently.

- Tracking and Communication: Look for suppliers who provide tracking options and clear communication throughout the shipping process.

Step 5: Negotiate Pricing and Terms

Engage in discussions to negotiate pricing and payment terms that fit your budget. Be transparent about your volume needs, as bulk orders may qualify for discounts. Ensure that you understand all costs involved, including shipping, installation, and any potential import duties.

- Request Samples: If possible, request samples of materials or components to evaluate quality before making a bulk purchase.

- Clarify Warranty Terms: Understand the warranty terms and conditions thoroughly, as these can vary significantly between suppliers.

Step 6: Plan for Installation and Support

Consider the installation process and whether you will need professional assistance. Some suppliers offer installation services or can recommend local contractors. Ensure you have a clear plan for assembly and maintenance, as this can impact the longevity and functionality of your pergola.

- Installation Instructions: Review the installation manual provided by the supplier to ensure clarity and ease of assembly.

- Post-Purchase Support: Confirm the availability of customer service for any post-purchase inquiries or support needed.

By following this checklist, B2B buyers can streamline their procurement process for a 10×12 pergola, ensuring a successful investment that meets their business needs.

Comprehensive Cost and Pricing Analysis for 10×12 pergola Sourcing

What Are the Key Cost Components in Sourcing a 10×12 Pergola?

When sourcing a 10×12 pergola, understanding the detailed cost structure is essential for effective budgeting and negotiation. The primary cost components include:

Illustrative image related to 10×12 pergola

-

Materials: The choice of materials significantly impacts pricing. Aluminum and cedar wood are popular options, each with its own cost implications. For instance, aluminum pergolas may be priced higher due to durability and lower maintenance, while cedar wood offers aesthetic appeal and natural resistance to decay but may require more maintenance.

-

Labor: Labor costs encompass assembly and installation. Depending on the complexity of the pergola design and local wage rates, these costs can vary. For international buyers, labor availability and costs can differ significantly, affecting overall pricing.

-

Manufacturing Overhead: This includes costs related to the production process, such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing can lower overhead costs, which may be reflected in competitive pricing.

-

Tooling: Initial tooling costs for custom designs can be substantial. If you’re sourcing a unique pergola design, factor in these costs, as they may be amortized over larger orders to reduce per-unit pricing.

-

Quality Control (QC): Implementing QC processes ensures product reliability, which is crucial for maintaining brand reputation. However, this may add to the overall cost, especially if third-party inspections are required.

-

Logistics: Shipping costs can vary greatly depending on the distance, weight, and dimensions of the pergola. This is particularly relevant for international buyers who need to consider tariffs, duties, and local transportation costs.

-

Margin: Suppliers typically include a profit margin that can vary based on market competition and product demand. Understanding the market rate for similar products can aid in evaluating supplier pricing.

How Do Price Influencers Affect 10×12 Pergola Costs?

Several factors influence the pricing of 10×12 pergolas, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounted rates. Suppliers may offer lower prices per unit for bulk orders, making it advantageous for businesses looking to stock inventory.

-

Specifications and Customization: Custom designs or specific features (like integrated electrical systems or unique finishes) can increase costs. Be clear about your requirements when negotiating to avoid unexpected price hikes.

-

Material Quality and Certifications: Pergolas built from high-quality materials or those that meet specific industry standards often command higher prices. Certifications can also add value, particularly in markets with stringent regulations.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge a premium but often provide better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting total costs.

What Are Some Buyer Tips for Cost-Efficiency in 10×12 Pergola Sourcing?

-

Negotiation: Engage in open discussions with suppliers about pricing and terms. Leverage competitive quotes from multiple vendors to negotiate better deals.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with maintenance, durability, and warranty. A slightly higher upfront cost may lead to significant savings over time if the product requires less upkeep.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, be mindful of exchange rates and local market conditions. These factors can significantly affect pricing and should be factored into your budget.

-

Evaluate Shipping Options: Compare different shipping methods and suppliers to find the most cost-effective solution. Consider lead times and reliability, as these can impact your project timelines.

In conclusion, understanding the comprehensive cost structure and pricing influencers for 10×12 pergolas can empower B2B buyers to make informed decisions and optimize their sourcing strategies. Always consult with suppliers for indicative prices, as these can fluctuate based on market conditions and specific requirements.

Alternatives Analysis: Comparing 10×12 pergola With Other Solutions

In the quest for effective outdoor shading solutions, the 10×12 pergola stands out as a versatile option. However, buyers should consider other alternatives that may better suit specific needs, preferences, or environmental conditions. This analysis compares the 10×12 pergola with two viable alternatives: retractable canopies and shade sails. Each option has its unique benefits and limitations, which are crucial for informed decision-making.

| Comparison Aspect | 10×12 Pergola | Retractable Canopy | Shade Sail |

|---|---|---|---|

| Performance | Provides solid structure, durable shading, and aesthetic appeal | Adjustable shade coverage and easy retraction for sun exposure | Flexible coverage and wind resistance, depending on installation |

| Cost | $1,999 – $2,649 | $300 – $1,500 | $150 – $600 |

| Ease of Implementation | Requires assembly; may need professional installation | Generally easy to install; DIY-friendly | Moderate installation complexity; requires proper anchoring |

| Maintenance | Low maintenance; materials like aluminum or wood last long | Moderate maintenance; fabric may need cleaning | Low to moderate; fabric may require occasional replacement |

| Best Use Case | Ideal for permanent outdoor structures, enhancing property value | Suitable for temporary or seasonal use, flexibility in shading | Great for irregularly shaped areas and providing a modern aesthetic |

What Are the Advantages and Disadvantages of Retractable Canopies Compared to a 10×12 Pergola?

Retractable canopies offer a flexible shading solution that allows users to adjust coverage based on the sun’s position. They are generally easier to install than a 10×12 pergola and can be retracted when not in use, which is ideal for seasonal climates. However, they may lack the structural integrity and aesthetic appeal of a pergola, making them less suitable for permanent installations. Additionally, the lifespan of a fabric canopy may be shorter than that of a durable pergola, requiring more frequent replacements.

How Do Shade Sails Compare to a 10×12 Pergola in Performance and Cost?

Shade sails are a modern, stylish alternative that can provide flexible shading options for various outdoor spaces. They are generally more cost-effective than a 10×12 pergola and can be installed in various configurations to suit unique landscape designs. However, their effectiveness can be compromised in extreme weather conditions, such as heavy winds or snow, and they may require more frequent maintenance. Unlike the solid structure of a pergola, shade sails may not enhance property value in the same way.

How Should B2B Buyers Decide Between These Options?

For B2B buyers evaluating outdoor shading solutions, the decision should hinge on specific project requirements, budget constraints, and long-term goals. If the focus is on creating a permanent and aesthetically pleasing outdoor structure that can enhance property value, a 10×12 pergola is the superior choice. Conversely, if flexibility and cost-effectiveness are priorities, retractable canopies or shade sails may be more appropriate. Assessing local climate conditions, installation capabilities, and intended use will ultimately guide buyers to the right solution for their needs.

Illustrative image related to 10×12 pergola

Essential Technical Properties and Trade Terminology for 10×12 pergola

What Are the Key Technical Properties of a 10×12 Pergola?

When considering a 10×12 pergola, several technical specifications are vital for ensuring that the structure meets your needs and expectations. Here are some critical specifications to be aware of:

-

Material Composition

Pergolas can be made from various materials, including wood, aluminum, and steel. Each material has distinct advantages; for instance, aluminum is lightweight and resistant to rust, while wood offers natural aesthetics but may require more maintenance. Understanding the material composition helps buyers assess longevity, maintenance requirements, and suitability for different climates. -

Load Capacity

This specification indicates the maximum weight the pergola can support, typically expressed in pounds per square foot (psf). For example, a pergola with a snow load capacity of 17.7 psf is suitable for regions experiencing heavy snowfall. Knowing the load capacity is crucial for ensuring the structure can withstand local weather conditions and prevent potential damage. -

Dimensions and Tolerances

While the overall size of a 10×12 pergola is standardized, tolerances in manufacturing can affect fit and assembly. Buyers should confirm that the dimensions provided are accurate and within acceptable tolerances to avoid installation issues. Accurate dimensions ensure that the pergola fits in the intended space and integrates well with existing landscaping or structures. -

Wind Resistance Rating

This rating indicates how well the pergola can withstand high winds, typically expressed in miles per hour (mph). A pergola rated for 82 mph is suitable for areas prone to storms. Knowing the wind resistance helps buyers ensure safety and longevity, particularly in regions with severe weather conditions. -

Warranty Period

The warranty offered by manufacturers can range from a few years to a lifetime, depending on the material and construction quality. A robust warranty reflects confidence in the product’s durability and can significantly impact a buyer’s decision-making process. Buyers should evaluate warranty terms to understand what is covered and for how long. -

Installation Requirements

Some pergolas come with pre-drilled holes and detailed assembly instructions, while others may require professional installation. Knowing the installation requirements helps buyers plan for additional labor costs or time commitments and ensures they can meet local building codes.

Which Trade Terminology Should B2B Buyers Understand for Pergola Purchases?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are essential terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pergolas, knowing OEMs can help buyers identify the source of materials or components, ensuring quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses, as it affects inventory management and cash flow. Buyers should negotiate MOQs to align with their purchasing needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods. Submitting an RFQ is a common practice in B2B transactions, allowing buyers to compare offers and make informed decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and reduces risks associated with international transactions. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning and ensures that buyers can meet deadlines for installation or other related activities. -

BOM (Bill of Materials)

A BOM is a comprehensive list of materials and components required to build a product. In the case of pergolas, a BOM allows buyers to understand what is included in their purchase and plan for any additional materials they may need.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when purchasing 10×12 pergolas, ensuring they select the right product for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the 10×12 pergola Sector

What are the Current Market Dynamics and Key Trends in the 10×12 Pergola Sector?

The global market for 10×12 pergolas is driven by a rising demand for outdoor living spaces, particularly in regions such as Africa, South America, the Middle East, and Europe. This growth is largely fueled by a shift in consumer preferences towards enhancing residential and commercial outdoor environments. Key trends include the increasing popularity of customizable and modular designs, which allow buyers to adapt structures to their specific needs and preferences. Technological advancements, such as the integration of smart features like adjustable roofs and built-in lighting, are also gaining traction among B2B buyers looking for innovative solutions.

Illustrative image related to 10×12 pergola

Emerging B2B sourcing trends indicate a shift towards online procurement platforms that streamline the purchasing process, allowing international buyers to access a wider array of products and suppliers. The use of data analytics for inventory management and demand forecasting is becoming common among manufacturers, helping them respond swiftly to market fluctuations. Additionally, an increasing focus on quality assurance and certifications is shaping buyer decisions, especially in markets like Europe where stringent regulations are in place.

How Does Sustainability and Ethical Sourcing Impact the 10×12 Pergola Market?

Sustainability is becoming a critical consideration for B2B buyers in the pergola sector, as consumers increasingly demand environmentally friendly products. The environmental impact of sourcing materials for 10×12 pergolas, such as wood and metals, is under scrutiny. Buyers are now prioritizing suppliers who offer sustainably sourced materials and adhere to ethical supply chain practices. Certifications such as Forest Stewardship Council (FSC) for wood and other ‘green’ certifications are becoming essential for companies looking to align with eco-conscious consumer values.

Ethical sourcing not only enhances brand reputation but also meets regulatory demands in various regions. Companies that adopt sustainable practices can benefit from reduced waste and energy consumption, ultimately leading to cost savings. Furthermore, the integration of recyclable materials in the manufacturing process of pergolas is seen as a significant trend, appealing to businesses that aim to minimize their carbon footprint.

What is the Brief Evolution of the Pergola Market?

The pergola has evolved significantly over the years, transitioning from a purely functional structure to a stylish outdoor feature that enhances aesthetic appeal. Historically, pergolas were primarily constructed from wood, serving as shade providers in gardens. However, advancements in materials and design have transformed the market. Today, aluminum and steel are popular choices due to their durability and low maintenance requirements.

The introduction of customizable features such as adjustable roofs and integrated lighting systems has further modernized the pergola, making it a desirable addition to both residential and commercial properties. As international markets continue to grow, the 10×12 pergola is positioned as a versatile solution that meets various consumer demands, blending functionality with contemporary design.

Illustrative image related to 10×12 pergola

Frequently Asked Questions (FAQs) for B2B Buyers of 10×12 pergola

-

How do I ensure the quality of the 10×12 pergola before purchase?

To ensure the quality of a 10×12 pergola, request detailed specifications and certifications from suppliers. Evaluate the materials used, such as aluminum, wood, or composite materials, for durability and weather resistance. Conduct supplier audits if possible and ask for references or samples of previous work. Additionally, inquire about warranty terms and after-sales support to gauge the manufacturer’s commitment to quality. -

What is the best material for a 10×12 pergola for outdoor use?

The best materials for outdoor 10×12 pergolas typically include aluminum, cedar wood, and composite materials. Aluminum is lightweight and resistant to rust, making it ideal for various climates. Cedar offers natural beauty and resistance to decay but may require more maintenance. Composite materials combine the aesthetic appeal of wood with the durability of synthetic options, minimizing upkeep while providing excellent structural integrity. -

What customization options are available for 10×12 pergolas?

Most suppliers offer customization options such as color, finish, and additional features like retractable canopies or integrated lighting. Discuss your specific needs with the supplier to explore options that enhance functionality and aesthetics. Customization may also include adjustments in dimensions or additional accessories, such as sidewalls or screens, to better suit your outdoor environment. -

What are the typical lead times for ordering 10×12 pergolas?

Lead times for ordering 10×12 pergolas can vary significantly depending on the supplier and customization requirements. Standard orders may take anywhere from 2 to 6 weeks for delivery, while customized orders can extend to 8 weeks or more. Always confirm lead times with the supplier during negotiations to align with your project schedules and ensure timely delivery. -

What are the minimum order quantities (MOQs) for 10×12 pergolas?

Minimum order quantities for 10×12 pergolas can vary based on the supplier’s production capacity and your specific requirements. Some manufacturers may offer MOQs as low as one unit for standard models, while others may require bulk orders for customization. Clarify MOQs during initial discussions to understand the flexibility in ordering and to plan your inventory accordingly. -

How do I handle shipping and logistics for international orders of 10×12 pergolas?

When handling shipping and logistics for international orders, work closely with the supplier to understand shipping options, costs, and timelines. Consider using freight forwarders experienced in handling outdoor structures to navigate customs regulations and ensure safe delivery. Always confirm the terms of delivery, including Incoterms (e.g., FOB, CIF), to determine responsibility for shipping costs and risks. -

What payment terms should I expect when purchasing a 10×12 pergola?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (typically 30-50%) with the balance due before shipping or upon delivery. Ensure you discuss payment options that suit your cash flow, such as letters of credit or installment plans for larger orders. Always clarify any potential additional costs, such as customs duties or taxes, to avoid surprises. -

What warranty options are available for 10×12 pergolas?

Warranty options for 10×12 pergolas usually range from one to ten years, depending on the material and manufacturer. Inquire about the specifics of the warranty, including what it covers—such as structural defects, weather resistance, and fading. Understanding warranty terms can provide peace of mind and help you assess the long-term value of your investment.

Top 6 10X12 Pergola Manufacturers & Suppliers List

1. Purple Leaf – 10′ x 12′ Pergola Kits

Domain: purpleleafshop.com

Registered: 2019 (6 years)

Introduction: 10′ x 12′ Pergola Kits, Black Friday Sale, Extra 15% Off, All Weather Use, Good Shelter For Garden, Available Colors: Grey, White, Bronze, Champagne, Wood Grain, Louvered Pergola Collection, Retractable Pergola, Enhanced with Accessories.

2. Mirador – MIRADOR 88S Charcoal Pergola

Domain: miradoroutdoor.com

Registered: 2023 (2 years)

Introduction: {“name”: “MIRADOR 88S 10’x12′ CHARCOAL PERGOLA”, “type”: “Louvered Aluminium Pergola”, “price”: “$2,199.00”, “color”: “Charcoal”, “dimensions”: “143.68 x 119.28 x 94.8 inches”, “materials”: “Aluminum + Alloy Steel”, “weight”: “395 pounds”, “warranty”: “3+1 years”, “louvers_opening_angle”: “93°”, “snow_load_capacity”: “13.8 lb/ft2”, “wind_rating”: “73 mph”, “features”: [“Adjustable Roof”, “Durable”…

3. Backyard Discovery – 12×10 Beaumont Pergola

Domain: backyarddiscovery.com

Registered: 2007 (18 years)

Introduction: {“name”: “12×10 Beaumont Pergola”, “sale_price”: “$1,399”, “regular_price”: “$1,499”, “savings”: “$100 (7%)”, “shipping”: “Free Shipping”, “available_sizes”: [“12×10 Beaumont Pergola”, “14×10 Beaumont Pergola”, “10×10 Beaumont Pergola”], “features”: {“wind_resistance”: “Pro-Tect™ tested to withstand up to 100 mph winds”, “warranty”: “5-year warranty”, “power_port”: “Patented PowerPort™ with 3 elec…

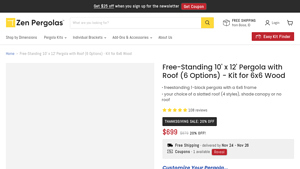

4. Zen Pergolas – Free-Standing 10×12 Pergola Kit

Domain: zenpergolas.com

Registered: 2017 (8 years)

Introduction: Free-Standing 10 x 12 Pergola with Roof – 20% Off. Free shipping from Boise, ID. Available as a DIY kit.

5. Construct101 – 10×12 Pergola Plans

Domain: construct101.com

Registered: 2013 (12 years)

Introduction: Pergola Plans – 10×12 includes a free PDF download, material list, drawings, measurements, and step-by-step instructions. Material List: 4 – 6×6 – 8′, 4 – 2×6 – 14′, 11 – 2×6 – 12′, 4 – 2×6 – 8′, 13 – 2×2 – 14′. Hardware: 4 – 6×6 post base, 16 – 9″ carriage bolts, nuts, washers, 3″ deck screws. Cutting List: 4 – 6×6 – 8′, 4 – 2×6 – 14′, 11 – 2×6 – 12′, 4 – 2×6 – 4′, 4 – 2×6 – 3′ 4 5/16″ long, 13 –…

6. Pergola Depot – 10×12 Big Kahuna LITE Pergola Kit

Domain: pergoladepot.com

Registered: 2007 (18 years)

Introduction: 10×12 Pergola Kit Big Kahuna LITE – Classic pergola design, ready-to-assemble kit built using premium quality lumber & hardware. Features include: 6×6 notched posts, 2×8 double beams, 2×6 angle braces, 2×2 top slats on 12 inch centers. Freestanding or attached options available. Maximum sun coverage of 90%. Engineered for 175 mph wind gusts. Price range: $6,120. Free shipping in lower 48 states. M…

Strategic Sourcing Conclusion and Outlook for 10×12 pergola

As the demand for outdoor living solutions continues to grow, the strategic sourcing of 10×12 pergolas presents a wealth of opportunities for international buyers. Key takeaways highlight the importance of selecting pergolas that offer durability, aesthetic appeal, and functional features, such as adjustable roofs and integrated lighting. Competitive pricing and robust warranties are also crucial factors that influence purchasing decisions.

By leveraging strategic sourcing, businesses can not only enhance their product offerings but also ensure they meet the diverse needs of customers across various regions, including Africa, South America, the Middle East, and Europe. The ability to source high-quality pergolas that comply with local regulations and weather conditions can significantly impact customer satisfaction and brand loyalty.

Looking ahead, B2B buyers should prioritize building relationships with reliable suppliers who can provide innovative solutions and superior support. Engaging with manufacturers that offer customization options and efficient logistics will further streamline operations and enhance competitive advantage. Embrace the potential of the 10×12 pergola market and take decisive steps towards securing your sourcing strategy for a prosperous future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to 10×12 pergola

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.