Introduction: Navigating the Global Market for fiberglass statue manufacturers

In the ever-evolving landscape of global commerce, sourcing fiberglass statues presents unique challenges for B2B buyers. With diverse applications ranging from public art installations to trade show displays, finding reliable manufacturers who can deliver quality and innovation is paramount. This comprehensive guide aims to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe—including regions like Saudi Arabia and Vietnam—with the insights needed to navigate this intricate market effectively.

Within these pages, you’ll discover a wealth of information tailored to empower your purchasing decisions. We delve into various types of fiberglass statues, their applications, and the nuanced processes involved in custom fabrication. Additionally, we provide actionable tips on supplier vetting, ensuring you partner with manufacturers who not only meet your specifications but also uphold high standards of quality and sustainability.

Understanding the cost structures associated with fiberglass statues is another critical aspect we address, helping you to budget effectively while maximizing value. As you explore this guide, you will gain the confidence needed to make informed choices that align with your business objectives, ultimately enhancing your project outcomes and boosting your competitive edge in the marketplace.

目次

- Top 7 Fiberglass Statue Manufacturers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fiberglass statue manufacturers

- Understanding fiberglass statue manufacturers Types and Variations

- Key Industrial Applications of fiberglass statue manufacturers

- 3 Common User Pain Points for ‘fiberglass statue manufacturers’ & Their Solutions

- Strategic Material Selection Guide for fiberglass statue manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for fiberglass statue manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiberglass statue manufacturers’

- Comprehensive Cost and Pricing Analysis for fiberglass statue manufacturers Sourcing

- Alternatives Analysis: Comparing fiberglass statue manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for fiberglass statue manufacturers

- Navigating Market Dynamics and Sourcing Trends in the fiberglass statue manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fiberglass statue manufacturers

- Strategic Sourcing Conclusion and Outlook for fiberglass statue manufacturers

- 重要な免責事項および利用規約

Understanding fiberglass statue manufacturers Types and Variations

| タイプ名 | 主な特徴 | 主なB2Bアプリケーション | バイヤーのための簡単な長所と短所 |

|---|---|---|---|

| Custom Fabricators | Tailored designs, high-quality materials, artistic input | Public art, trade show displays, mascots | 長所だ: Unique creations, high customization. 短所だ: リードタイムが長く、コストが高くなる可能性がある。 |

| Mass Production Manufacturers | Standardized designs, efficient production processes | Retail displays, event decorations | 長所だ: Cost-effective, faster delivery. 短所だ: Limited customization options, less artistic input. |

| Specialty Theme Creators | Focus on themed attractions, interactive elements | Amusement parks, promotional events | 長所だ: Engaging designs, strong visual impact. 短所だ: Niche market, may require specific knowledge. |

| Restoration and Repair Services | Expertise in maintaining and restoring existing statues | Museums, public spaces, historical sites | 長所だ: Preserves value, extends lifespan. 短所だ: May be costly, depends on availability of parts. |

| Eco-Friendly Manufacturers | Use of sustainable materials and processes | Green initiatives, environmentally conscious projects | 長所だ: Appeals to eco-conscious clients, often durable. 短所だ: May be pricier, limited availability. |

What Are the Key Characteristics of Custom Fabricators?

Custom fabricators specialize in creating unique fiberglass statues tailored to specific client needs. They often utilize high-quality materials and advanced techniques, including 3D modeling and computerized sculpting. B2B buyers should consider their project’s complexity and desired artistic input, as these manufacturers can produce intricate designs that resonate with local culture or branding. However, the lead time may be longer, and costs can vary significantly based on customization.

How Do Mass Production Manufacturers Operate?

Mass production manufacturers focus on efficiency and standardized designs, allowing them to produce fiberglass statues at scale. This approach is suitable for B2B applications like retail displays and event decorations, where uniformity and rapid delivery are essential. Buyers benefit from lower costs and quicker turnaround times but may find limited customization options. It’s crucial to assess whether a generic design meets branding or thematic requirements.

What Makes Specialty Theme Creators Unique?

Specialty theme creators concentrate on producing themed attractions and interactive elements, making them ideal for amusement parks and promotional events. Their designs often prioritize visual engagement and user interaction, appealing to businesses looking to create memorable experiences. While they offer unique, eye-catching products, buyers should be aware that these manufacturers may cater to niche markets, necessitating specific knowledge or expertise in themed designs.

Why Are Restoration and Repair Services Important?

Restoration and repair services are crucial for maintaining and preserving existing fiberglass statues, particularly in museums or historical sites. These specialists can rejuvenate aging sculptures, ensuring they retain their aesthetic and historical value. B2B buyers should consider the long-term investment in preserving their assets, though costs can be significant. Availability of parts and expertise in restoration techniques are key factors to evaluate when selecting a service provider.

What Are the Benefits of Eco-Friendly Manufacturers?

Eco-friendly manufacturers prioritize sustainable materials and processes, appealing to businesses focused on green initiatives. Their products often align with environmentally conscious projects, making them attractive to B2B buyers looking to enhance their corporate social responsibility. While these statues can be durable and appealing, buyers should consider potential cost implications and the availability of eco-friendly options in their region.

Key Industrial Applications of fiberglass statue manufacturers

| 業界/セクター | Specific Application of fiberglass statue manufacturers | ビジネスにとっての価値/利益 | このアプリケーションにおける主な調達上の考慮事項 |

|---|---|---|---|

| 観光とホスピタリティ | Custom sculptures for attractions and parks | Enhances visitor experience and boosts local tourism | Durability, weather resistance, and customization options |

| Entertainment and Events | Themed displays for trade shows and festivals | 通行量とブランド認知度の向上 | Design flexibility, production timelines, and logistics |

| パブリック・アートとコミュニティ・プロジェクト | Art installations for public spaces | Promotes community engagement and local pride | Artistic creativity, project management, and community input |

| 教育と博物館 | インタラクティブな展示と教育的彫刻 | Enhances learning experiences and attracts visitors | Educational relevance, safety standards, and maintenance |

| 小売と広告 | Eye-catching retail displays and promotional sculptures | 顧客の注目を集め、販売を促進する | Branding alignment, size specifications, and installation support |

How Are Fiberglass Statue Manufacturers Used in the Tourism and Hospitality Sector?

Fiberglass statue manufacturers play a pivotal role in the tourism and hospitality industry by creating custom sculptures that enhance attractions and parks. These statues serve as focal points for visitors, elevating the overall experience and encouraging longer stays. For international buyers, particularly in regions like Africa and South America, sourcing durable and weather-resistant materials is critical to withstand local climates. Additionally, customization options allow for the incorporation of cultural elements that resonate with local tourists, making the attractions more appealing.

What Role Do Fiberglass Statues Play in Entertainment and Events?

In the entertainment sector, fiberglass statues are essential for creating themed displays at trade shows and festivals. These unique installations attract attention, increase foot traffic, and enhance brand visibility. Buyers must consider the design flexibility of the sculptures, ensuring they align with their brand messaging. Timely production and reliable logistics are also crucial, particularly for international events in the Middle East and Europe, where shipping timelines can impact promotional strategies.

Why Are Fiberglass Statues Important for Public Art and Community Projects?

Fiberglass statues are often utilized in public art projects to foster community engagement and pride. These installations can transform public spaces, making them more inviting and culturally rich. For international buyers, it’s essential to collaborate closely with local artists and community stakeholders to ensure the artwork reflects regional values and aesthetics. Additionally, effective project management and clear communication throughout the process can enhance the success of these initiatives.

How Do Fiberglass Statues Enhance Education and Museums?

In educational institutions and museums, fiberglass statues serve as interactive displays that enhance learning experiences. They can illustrate historical events, scientific concepts, or artistic expressions, making education more engaging. Buyers need to ensure that the sculptures meet safety standards and are suitable for diverse audiences. Furthermore, maintenance considerations are critical, especially for institutions with high foot traffic, to keep exhibits looking pristine and educationally relevant.

Illustrative image related to fiberglass statue manufacturers

What Benefits Do Fiberglass Statues Provide in Retail and Advertising?

Retail and advertising sectors leverage fiberglass statues to create eye-catching displays that capture customer attention and drive sales. These promotional sculptures can be designed to align with brand identity and messaging, making them effective marketing tools. When sourcing, businesses should focus on size specifications and the ability to support installation efforts. International buyers must also consider cultural nuances in design to ensure the sculptures resonate with local customers, enhancing their promotional impact.

3 Common User Pain Points for ‘fiberglass statue manufacturers’ & Their Solutions

Scenario 1: Navigating Quality Assurance for Custom Designs

問題だ: B2B buyers often face the daunting task of ensuring the quality and durability of custom fiberglass statues. Given the wide variety of manufacturers, there can be significant discrepancies in production standards. A buyer may receive a beautifully crafted statue only to find it deteriorates quickly due to poor materials or craftsmanship. This situation can lead to additional costs in repairs or replacements, and can severely impact the buyer’s reputation if the statues are intended for public display or high-profile events.

解決策 To mitigate this risk, buyers should conduct thorough due diligence on potential manufacturers. Start by requesting samples of previous work to assess the quality firsthand. Look for manufacturers who provide detailed descriptions of the materials used, such as high-quality resins or UV-resistant coatings, which enhance durability. Additionally, establish a clear communication channel where you can discuss your specific needs and expectations. A well-structured contract that includes quality benchmarks and timelines can also safeguard your interests. Finally, consider visiting the manufacturing facility if possible, to observe their processes and capabilities in person.

Scenario 2: Managing Timelines and Delivery Expectations

問題だ: Timely delivery of fiberglass statues can be a significant concern for B2B buyers, particularly when the statues are needed for specific events, exhibitions, or marketing campaigns. Manufacturers may face unexpected delays due to production issues, material shortages, or logistical challenges. Such delays can disrupt marketing plans and result in financial losses or missed opportunities for visibility.

解決策 To avoid delivery issues, buyers should establish a clear timeline with the manufacturer before placing an order. This timeline should include milestones for design approvals, production phases, and shipping dates. It’s essential to communicate your deadlines explicitly and inquire about the manufacturer’s capacity to meet those timelines. Additionally, consider building in buffer time to account for unforeseen delays. Engaging with manufacturers who have a proven track record of timely deliveries and who offer transparency about their production schedules will significantly reduce the likelihood of disruptions.

Illustrative image related to fiberglass statue manufacturers

Scenario 3: Ensuring Customization Meets Market Demands

問題だ: Buyers often struggle with getting customized fiberglass statues that align with their specific branding or cultural narratives. Whether creating a mascot for a sports team, a public art installation, or themed attractions, the challenge lies in effectively translating a vision into a tangible product. Misalignment between the buyer’s expectations and the manufacturer’s understanding can lead to dissatisfaction with the final product, resulting in wasted resources and time.

解決策 To ensure that customizations meet market demands, initiate a collaborative design process with the manufacturer. Provide comprehensive briefs that include visual references, color schemes, and any cultural significance tied to the designs. Utilizing 3D modeling technology can also help visualize the final product before production begins, allowing for adjustments to be made early in the process. Regular check-ins during the design phase will help ensure alignment and facilitate open communication about any necessary changes. Lastly, consider seeking feedback from stakeholders or target audiences on preliminary designs to refine the final output further and ensure it resonates well within the intended market.

Strategic Material Selection Guide for fiberglass statue manufacturers

When selecting materials for fiberglass statues, manufacturers must consider various factors that impact performance, durability, and cost. Below are analyses of four common materials used in the production of fiberglass statues, focusing on their properties, advantages and disadvantages, and specific considerations for international B2B buyers.

ガラス繊維強化プラスチック(FRP)の主な特性とは?

Fiberglass Reinforced Plastics (FRP) are widely used in statue manufacturing due to their excellent strength-to-weight ratio. FRP can withstand a wide range of temperatures, typically between -40°F to 200°F, and exhibits good resistance to corrosion, making it suitable for outdoor applications. The material’s flexibility allows for intricate designs, which is essential for artistic sculptures.

長所だ: FRP is lightweight, making transportation and installation easier. It is also highly durable, withstanding harsh weather conditions and UV exposure without significant degradation.

短所だ: The manufacturing process can be complex and labor-intensive, leading to higher production costs. Additionally, while FRP is strong, it may not be as impact-resistant as some metals, which could be a consideration for high-traffic areas.

アプリケーションへの影響 FRP is compatible with various finishes, including paints and coatings, allowing for customization in aesthetics. This versatility is beneficial for projects targeting tourism and public art initiatives.

How Do Polyurethane and Epoxy Resins Compare in Terms of Performance?

Polyurethane and epoxy resins are popular choices for fiberglass statue manufacturing due to their excellent adhesion and durability. Polyurethane resin is particularly noted for its flexibility and impact resistance, while epoxy resin is known for its superior strength and chemical resistance.

長所だ: Both resins provide a high-quality finish and can be formulated to enhance UV resistance. Polyurethane is generally more cost-effective and easier to work with, while epoxy offers superior bonding strength.

短所だ: Polyurethane can be less durable in extreme temperatures compared to epoxy, which might limit its use in certain climates. Epoxy, while stronger, can be more expensive and may require specialized handling during production.

アプリケーションへの影響 The choice between polyurethane and epoxy can significantly affect the statue’s longevity and maintenance requirements, especially in regions with extreme weather conditions.

What Are the Benefits of Using Gelcoat in Fiberglass Statues?

Gelcoat is a specialized coating applied to fiberglass products to enhance surface quality and durability. It provides a smooth finish and can be pigmented to achieve various colors.

長所だ: Gelcoat enhances UV resistance, protecting the underlying fiberglass from sun damage. It also adds a layer of protection against moisture and environmental pollutants.

短所だ: The application of gelcoat can increase manufacturing time and costs. Additionally, if not properly maintained, gelcoat can chip or fade over time, requiring periodic touch-ups.

Illustrative image related to fiberglass statue manufacturers

アプリケーションへの影響 For international buyers, particularly in regions with high sun exposure, gelcoat can significantly extend the life of a statue, making it a valuable investment.

What Considerations Should International Buyers Keep in Mind?

International B2B buyers should be aware of compliance standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). These standards ensure that materials meet specific safety and performance criteria. Additionally, cultural preferences may influence material choice; for example, certain colors or designs may be favored in specific regions.

グラスファイバー像の素材選択に関する総括表

| 素材 | Typical Use Case for fiberglass statue manufacturers | 主な利点 | 主な欠点/制限 | 相対コスト(低/中/高) |

|---|---|---|---|---|

| ガラス繊維強化プラスチック(FRP) | Public art installations, outdoor sculptures | Lightweight and durable | 複雑な製造工程 | ミディアム |

| Polyurethane Resin | Custom sculptures requiring flexibility | コストパフォーマンスが高く、作業が容易 | Less durable in extreme temperatures | 低い |

| エポキシ樹脂 | High-strength statues for harsh environments | Superior bonding strength | Higher cost and requires specialized handling | 高い |

| Gelcoat | Finishing layer for enhanced aesthetics | UV and moisture protection | Can chip or fade without maintenance | ミディアム |

This guide aims to provide valuable insights for B2B buyers in selecting the right materials for fiberglass statues, ensuring that they meet performance, aesthetic, and regulatory requirements in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for fiberglass statue manufacturers

What Are the Main Stages of the Manufacturing Process for Fiberglass Statues?

The manufacturing process of fiberglass statues involves several critical stages, each designed to ensure the final product meets high standards of quality and durability.

Illustrative image related to fiberglass statue manufacturers

素材の準備:どのような材料が使われ、どのように加工されるのか?

The primary materials used in fiberglass statue production include fiberglass reinforced plastic (FRP), resins, and additives. The process begins with the selection of high-quality raw materials, which are often sourced from reputable suppliers. Fiberglass strands are typically combined with a resin, which may be polyester or epoxy, depending on the desired properties of the final product.

Preparation also involves mixing these materials in precise ratios to achieve optimal strength and flexibility. This mixture is then poured into molds, which can be custom-designed to match the specifications of the statue. The quality of the raw materials significantly affects the durability and appearance of the final product, making it imperative for manufacturers to choose reliable sources.

Forming: How Are Fiberglass Statues Shaped?

Forming is a crucial stage where the prepared materials are shaped into the desired statue form. This can be accomplished through various techniques, including:

-

Hand Lay-Up: This traditional method involves applying layers of resin and fiberglass mat by hand into a mold. It allows for high levels of detail and customization.

-

Spray-Up: This technique uses a spray gun to apply resin and chopped fiberglass simultaneously into the mold, which is faster than hand lay-up but may offer less detail.

-

Vacuum Infusion: A more modern technique, vacuum infusion involves placing dry fiberglass in a mold and then drawing resin through it using a vacuum. This ensures even distribution and reduces the amount of resin used.

-

Rotational Molding: Often used for larger, hollow statues, this method involves rotating a mold filled with resin and fiberglass to achieve uniform thickness.

Each technique offers distinct advantages, and the choice often depends on the specific requirements of the project, including size, detail, and budget.

組み立て:異なる部品はどのように組み合わされるのか?

Once the individual components of the statue have been formed, they are assembled. This may involve attaching multiple parts, such as limbs, heads, or accessories, using strong adhesives or mechanical fasteners.

Illustrative image related to fiberglass statue manufacturers

In some cases, internal supports or frameworks are added to enhance structural integrity. The assembly process must be carefully managed to ensure that all components fit together seamlessly, as any misalignment can affect the aesthetic quality and durability of the statue.

Finishing: What Techniques Are Used to Ensure Quality and Aesthetics?

The finishing stage is where the statue is prepared for its final presentation. This includes sanding, painting, and applying protective coatings.

- サンディング is essential to achieve a smooth surface, which is critical for aesthetic appeal.

- 絵画 can be done using high-quality, UV-resistant paints to ensure the colors remain vibrant over time, especially in outdoor installations.

- 保護コーティング are often applied to enhance weather resistance and prolong the life of the statue.

Quality control during the finishing stage is vital, as it directly impacts the visual appeal and longevity of the final product.

What Quality Assurance Measures Are Commonly Implemented in Fiberglass Statue Manufacturing?

Quality assurance (QA) is a critical aspect of fiberglass statue manufacturing, ensuring that products meet both customer expectations and regulatory standards.

What International Standards Are Relevant for Fiberglass Statue Manufacturers?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for quality management systems. Compliance with these standards helps ensure that processes are efficient and that products are consistently high-quality.

In addition, industry-specific certifications like CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) standards may also be relevant, depending on the application of the fiberglass statues.

製造工程における品質管理の重要なチェックポイントとは?

品質管理には、製造工程を通じていくつかのチェックポイントがある:

-

インカミング・クオリティ・コントロール(IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards before they are used in production.

-

インプロセス品質管理(IPQC): During manufacturing, regular inspections are conducted to monitor the forming, assembly, and finishing stages. This helps catch any defects early in the process.

-

最終品質管理(FQC): Once the statue is completed, a thorough inspection is performed to assess the overall quality, including structural integrity, aesthetics, and compliance with specifications.

品質を保証するために、どのような一般的な試験方法が用いられているか?

Common testing methods for fiberglass statues may include:

- 目視検査: A thorough visual check for surface defects, color consistency, and overall appearance.

- 機械的試験: Assessing the strength and durability of the material through stress tests.

- 耐候性試験: Exposing samples to various environmental conditions to ensure they can withstand outdoor elements.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensure reliability and compliance with local regulations.

What Are Effective Methods for Supplier Audits?

-

サプライヤーの監査 Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and adherence to international standards directly.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can provide insights into their processes and the results of various tests conducted.

-

第三者による検査: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control practices and product quality.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate additional complexities in quality control, such as differing regulatory standards and cultural practices. Understanding these nuances is essential to ensure compliance and satisfactory outcomes.

- 規制遵守: Buyers should familiarize themselves with local regulations regarding product safety and environmental impact, which may differ from their home countries.

- 文化的配慮: Communication styles and business practices can vary, making it essential to establish clear expectations and maintain open lines of communication.

By understanding the manufacturing processes and quality assurance practices of fiberglass statue manufacturers, B2B buyers can make informed decisions and foster successful partnerships in this dynamic industry.

Illustrative image related to fiberglass statue manufacturers

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiberglass statue manufacturers’

はじめに

This sourcing guide serves as a practical checklist for B2B buyers seeking to procure fiberglass statues from manufacturers. It outlines essential steps to ensure that you select a supplier that meets your specific needs, maintains quality standards, and delivers on time. By following this guide, you can streamline your procurement process and build a successful partnership.

ステップ1: 技術仕様の定義

Before reaching out to suppliers, it’s crucial to clarify your project requirements. This includes dimensions, design complexity, color specifications, and durability needs. A well-defined specification helps manufacturers understand your vision and enables them to provide accurate quotes and timelines.

- Consider the purpose of the statue: Is it for indoor display or outdoor installation?

- Identify materials: Will you require weather-resistant finishes for outdoor use?

ステップ2: Research Potential Manufacturers

Conduct thorough research to identify reputable fiberglass statue manufacturers. Look for companies with a strong portfolio, positive customer reviews, and relevant industry experience. This groundwork can help you create a shortlist of potential suppliers that align with your requirements.

- Utilize online platforms: Websites, social media, and industry forums can provide insights into a manufacturer’s reputation.

- Check for previous projects: Review case studies or galleries that showcase their work in your desired area.

ステップ3: サプライヤー候補の評価

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; personal testimonials can provide invaluable insights into a manufacturer’s reliability and quality.

- Ask for client references: Speak directly to previous clients about their experiences.

- Review their production capabilities: Ensure the manufacturer can handle your project size and complexity.

ステップ4: サプライヤーの証明書を確認する

Ensure that the manufacturers you are considering have the necessary certifications for quality and safety standards. This is especially important for projects that require compliance with specific regulations or industry standards.

- Look for ISO certifications: These indicate adherence to international quality management standards.

- Check environmental certifications: If sustainability is a priority, confirm that they use eco-friendly materials and processes.

ステップ5: 詳細見積り依頼

Once you’ve narrowed down your options, request detailed quotes from your selected manufacturers. A comprehensive quote should include pricing, timelines, payment terms, and any additional costs such as shipping or installation.

- Compare the quotes: Look for transparency in pricing and clarity in terms of what is included.

- Inquire about payment terms: Understand the deposit requirements and payment milestones throughout the project.

ステップ6: Discuss Communication and Project Management

Effective communication is vital for the success of any B2B partnership. Discuss how the manufacturer manages projects and their preferred communication channels. Establishing clear lines of communication can prevent misunderstandings and ensure timely updates.

- Ask about project timelines: Ensure that they can meet your deadlines.

- Clarify points of contact: Identify who will be your main contact throughout the project.

ステップ7: Finalize the Agreement

After selecting your preferred manufacturer, review and finalize the contract. Ensure that all terms discussed are documented, including delivery timelines, quality assurance procedures, and after-sales support.

- Consult legal advice if necessary: A clear contract protects both parties and outlines responsibilities.

- Establish a follow-up plan: Set expectations for regular updates and quality checks throughout the project lifecycle.

By following this checklist, B2B buyers can make informed decisions when sourcing fiberglass statue manufacturers, ensuring a successful procurement process that meets their unique needs.

Illustrative image related to fiberglass statue manufacturers

Comprehensive Cost and Pricing Analysis for fiberglass statue manufacturers Sourcing

What Are the Key Cost Components for Fiberglass Statue Manufacturing?

In sourcing fiberglass statues, understanding the cost structure is critical for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

材料: The type and quality of fiberglass resin used significantly influence costs. High-quality, environmentally friendly materials may come at a premium but can enhance durability and aesthetic appeal. Additionally, custom paint finishes or unique additives can also add to material costs.

-

労働: Skilled labor is essential in the production of fiberglass statues, particularly for custom designs. Labor costs can vary based on geographical location and the skill level of the workforce. Regions with higher labor costs may result in higher overall prices for the finished product.

-

製造間接費: This includes costs related to factory operations such as utilities, equipment maintenance, and administrative expenses. These costs are typically factored into the price per unit.

-

工具: For custom projects, initial tooling costs can be substantial, particularly for complex designs that require specialized molds or machinery. This upfront investment often impacts pricing, especially for low-volume orders.

-

品質管理(QC): Ensuring that products meet specified standards incurs additional costs. Rigorous QC processes are necessary to maintain quality, especially when dealing with international standards and certifications.

-

物流: Shipping and transportation costs can vary widely based on the destination and the terms of shipping (Incoterms). International shipments may involve customs duties and tariffs, which should be factored into the total cost.

-

マージン: Manufacturers typically apply a profit margin that reflects the complexity of the project and market demand. Understanding the balance between cost and quality is vital for buyers to ensure they receive value for their investment.

How Do Price Influencers Affect Fiberglass Statue Costs?

Several factors influence the pricing of fiberglass statues, impacting the final costs for buyers.

-

数量と最小発注量(MOQ): Manufacturers often provide discounts for bulk orders, which can substantially lower the cost per unit. Conversely, small orders may incur higher costs due to the fixed costs associated with production.

-

仕様とカスタマイズ: Unique designs or specifications typically increase costs. Customization can involve additional labor and material costs, especially if intricate detailing or specialized finishes are required.

-

品質と認証: Statues that meet specific quality standards or certifications may come at a higher price. Buyers should assess whether these certifications are necessary for their target markets.

-

サプライヤー要因: The reputation and reliability of the supplier play a crucial role in pricing. Established manufacturers with a track record of quality and service may charge more but could provide better assurance of meeting delivery timelines and quality standards.

-

インコタームズ: Understanding the shipping terms is essential for budgeting. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total cost of ownership.

What Buyer Tips Can Help Navigate Cost Negotiations?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential.

-

Negotiate Volume Discounts: If possible, consolidate orders to meet MOQ thresholds for better pricing. This approach not only reduces costs but can also improve supplier relationships.

-

総所有コストの評価: Consider not just the purchase price but also shipping, potential tariffs, maintenance, and durability of the statues. A higher upfront cost may lead to long-term savings if the product requires less maintenance or has a longer lifespan.

-

Research and Compare Suppliers: Conduct thorough research to compare pricing, quality, and service offerings. Request quotes from multiple suppliers and ask for samples when possible to assess quality before making a decision.

-

Clarify Specifications Upfront: Ensure that all design specifications and quality expectations are clearly defined before negotiations. This clarity can prevent misunderstandings and unexpected costs later in the process.

-

地域市場のダイナミクスを理解する: Familiarize yourself with local market conditions and potential competition. This knowledge can provide leverage during negotiations and help in making informed purchasing decisions.

参考価格に関する免責事項

Pricing for fiberglass statues can vary widely based on the factors discussed. It is advisable to obtain detailed quotes from manufacturers and to consider all associated costs in your budgeting process. Prices mentioned in this analysis are indicative and subject to change based on market conditions and individual project specifications.

Illustrative image related to fiberglass statue manufacturers

Alternatives Analysis: Comparing fiberglass statue manufacturers With Other Solutions

When considering the procurement of statues for commercial, artistic, or promotional purposes, buyers often explore alternatives to fiberglass statue manufacturers. These alternatives can include other materials or methods of creation that may better suit specific project needs. In this analysis, we will evaluate fiberglass statue manufacturers against two viable alternatives: 3D Printing and Traditional Stone Sculpting.

| 比較の側面 | Fiberglass Statue Manufacturers | 3Dプリンティング | Traditional Stone Sculpting |

|---|---|---|---|

| パフォーマンス | Durable, weather-resistant, customizable designs | Highly detailed, can replicate complex designs | Unique, timeless aesthetic, durable |

| コスト | Moderate to high, depending on customization | Variable, generally lower for small runs | High, especially for labor-intensive projects |

| 実施しやすさ | Requires skilled labor for production and installation | Relatively easy for small projects, but large items can be challenging | Labor-intensive, requires skilled artisans |

| メンテナンス | Low maintenance; withstands weather | Low maintenance, but depends on material used | Requires regular upkeep, can weather over time |

| ベスト・ユースケース | Public art, mascots, advertising displays | Prototyping, small custom projects | High-end art pieces, permanent installations |

What Are the Pros and Cons of 3D Printing as an Alternative to Fiberglass Statues?

3D printing is an innovative technology that allows for the creation of highly detailed sculptures and models. One of its main advantages is the ability to produce intricate designs quickly and at a lower cost for small runs. This method is particularly effective for prototyping and creating customized items without the need for extensive tooling. However, the limitations in size and material strength can pose challenges for larger projects, and the durability of 3D printed items can vary significantly based on the materials used.

How Does Traditional Stone Sculpting Compare to Fiberglass Statues?

Traditional stone sculpting is revered for its timeless beauty and durability, often resulting in unique pieces that can last for centuries. The aesthetic value and craftsmanship involved in stone sculptures can add significant prestige to any project. However, the costs can be prohibitively high, and the labor required is intensive, making it less feasible for large-scale or commercial applications. Additionally, the time required for sculpting can delay project timelines.

B2Bバイヤーはどのように自社のニーズに合ったソリューションを選択できるのか?

In choosing the right solution, B2B buyers should evaluate their specific project requirements, including budget constraints, the desired aesthetic, and the intended use of the statue. For projects requiring durability and customization, fiberglass statue manufacturers offer a compelling option due to their versatility and weather resistance. Conversely, for those seeking intricate details in smaller runs, 3D printing might be the ideal choice. If the goal is to create a prestigious, long-lasting piece, traditional stone sculpting could be the best fit, despite its higher costs and longer lead times. By carefully considering these factors, buyers can make informed decisions that align with their artistic and commercial objectives.

Illustrative image related to fiberglass statue manufacturers

Essential Technical Properties and Trade Terminology for fiberglass statue manufacturers

What Are the Key Technical Properties of Fiberglass Statues for Manufacturers?

When selecting fiberglass statues for manufacturing, understanding the technical properties is crucial. Here are several key specifications that impact the quality, durability, and suitability of fiberglass statues for various applications:

-

素材グレード

The material grade refers to the quality of the fiberglass resin used in production. Higher-grade resins, such as those reinforced with additives for UV resistance, are vital for outdoor statues exposed to harsh environmental conditions. Choosing the right grade ensures longevity and maintains aesthetic appeal, which is especially important for public installations and commercial displays. -

寛容

Tolerance indicates the permissible variation in dimensions during manufacturing. For fiberglass statues, maintaining tight tolerances (typically ±1-3 mm) is essential to ensure that multiple pieces fit together correctly, especially when creating large installations or replicating detailed designs. Precise tolerances reduce the risk of costly adjustments and enhance the overall quality of the finished product. -

耐衝撃性

This property measures how well the fiberglass can withstand mechanical stress and impacts. Statues intended for high-traffic areas or outdoor settings must have high impact resistance to prevent damage from collisions or environmental forces. Manufacturers often test this property to certify that the finished product can endure real-world conditions, enhancing customer satisfaction and reducing warranty claims. -

重量

The weight of fiberglass statues is a significant consideration, particularly for shipping and installation. Lighter statues are easier to transport and install, which can save on logistical costs. However, manufacturers must balance weight with durability and stability, ensuring that the statues remain anchored and secure in various environments. -

仕上げの品質

The finish quality encompasses the surface smoothness, color consistency, and overall aesthetic appeal of the fiberglass statue. A high-quality finish not only enhances the visual impact but also protects against weathering and UV damage. Manufacturers often offer a range of finishes, from matte to glossy, allowing for customization based on client preferences.

What Are Common Trade Terms Used by Fiberglass Statue Manufacturers?

Understanding industry terminology is essential for effective communication and negotiation in the fiberglass statue manufacturing sector. Here are some commonly used trade terms:

-

OEM(相手先ブランド製造)

This term refers to companies that produce products or components that are marketed under another brand’s name. In the fiberglass industry, an OEM might create custom statues for a brand that will sell them as part of their merchandise. B2B buyers should consider OEM partnerships to leverage manufacturing expertise while focusing on branding and marketing. -

MOQ(最小注文数量)

MOQ indicates the smallest number of units a manufacturer is willing to produce or sell. This term is crucial for B2B buyers to understand, as it can affect inventory management and cash flow. Knowing the MOQ helps buyers gauge initial investment and plan purchases accordingly. -

RFQ(見積依頼)

An RFQ is a standard business process where buyers request pricing information from suppliers for specific products. It helps manufacturers understand buyer needs and provide tailored quotes. For B2B buyers, submitting an RFQ can lead to better pricing and terms, especially when ordering in bulk. -

インコタームズ(国際商業取引用語)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B transactions, as they dictate who bears the risk and costs at various stages of transport. -

リードタイム

Lead time refers to the time taken from placing an order to delivery. In the fiberglass statue manufacturing industry, understanding lead times is critical for planning projects and managing customer expectations. Buyers should inquire about lead times during negotiations to ensure timely completion of their projects.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, enhance collaboration with manufacturers, and ensure successful project outcomes in the fiberglass statue market.

Illustrative image related to fiberglass statue manufacturers

Navigating Market Dynamics and Sourcing Trends in the fiberglass statue manufacturers Sector

What Are the Key Trends Influencing the Global Fiberglass Statue Manufacturers Market?

The fiberglass statue manufacturing sector is witnessing significant growth driven by globalization and the increasing demand for customized sculptures across various industries, including tourism, entertainment, and public art. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek unique and engaging art pieces, manufacturers are pivoting toward advanced technologies such as 3D printing and computer-aided design (CAD). These technologies not only enhance the precision and creativity of sculptures but also allow for rapid prototyping, enabling manufacturers to respond swiftly to market demands.

Emerging trends such as the rise of experiential marketing are also influencing the market. Businesses are increasingly investing in eye-catching fiberglass displays and sculptures to attract customers at trade shows and public events. This trend is particularly prominent in regions like the Middle East and Europe, where large-scale exhibitions are commonplace. Moreover, the demand for sustainable and environmentally friendly materials is reshaping sourcing strategies. Manufacturers are now focusing on eco-friendly resins and materials that minimize environmental impact, appealing to the growing base of environmentally conscious buyers.

How Is Sustainability and Ethical Sourcing Transforming the Fiberglass Statue Manufacturing Industry?

Sustainability is becoming a pivotal consideration in the fiberglass statue manufacturing sector. The environmental impact of production processes, particularly in terms of waste and emissions, has led to increased scrutiny from both consumers and regulatory bodies. As such, manufacturers are adopting greener practices by utilizing sustainable materials and reducing waste during production. The incorporation of recyclable resins and biodegradable materials is gaining traction, allowing companies to align their offerings with the values of eco-conscious buyers.

Illustrative image related to fiberglass statue manufacturers

Moreover, ethical sourcing is essential for establishing trust and transparency in supply chains. B2B buyers are increasingly prioritizing manufacturers who demonstrate a commitment to fair labor practices and ethical sourcing of raw materials. Certifications such as ISO 14001 for environmental management and other green certifications signal a manufacturer’s dedication to sustainability. These certifications not only enhance a company’s reputation but also provide a competitive edge in a market where buyers are more informed and concerned about the ethical implications of their purchases.

What Is the Historical Context of the Fiberglass Statue Manufacturing Sector?

The fiberglass statue manufacturing industry has evolved significantly since its inception in the mid-20th century. Originally used for simple decorative objects, fiberglass became popular due to its lightweight, durable, and versatile properties. Over the decades, advancements in technology and techniques have transformed the production of fiberglass sculptures, allowing for more intricate designs and larger-scale projects. The introduction of computer-aided design and 3D printing in recent years has further revolutionized the sector, enabling manufacturers to create highly customized pieces that meet specific client needs.

As the market continues to grow, the emphasis on quality, creativity, and sustainability will likely shape the future of fiberglass statue manufacturing, providing ample opportunities for international B2B buyers seeking unique and impactful art solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of fiberglass statue manufacturers

-

How can I ensure the quality of fiberglass statues from manufacturers?

To guarantee the quality of fiberglass statues, it’s crucial to vet potential manufacturers thoroughly. Start by requesting samples or references from previous clients to assess craftsmanship. Look for manufacturers that employ quality assurance processes, including material testing and final inspections. Additionally, inquire about their use of environmentally friendly materials and advanced manufacturing techniques. Establishing clear communication and expectations upfront can help mitigate risks and ensure that the final product meets your standards. -

What customization options are typically available for fiberglass statues?

Most fiberglass statue manufacturers offer a variety of customization options, including size, design, color, and finish. You can provide sketches or concepts for a unique statue, and many manufacturers will work closely with you to bring your vision to life. Some companies also offer custom painting and thematic designs tailored to your brand or project needs. Be sure to discuss your specific requirements during the initial consultation to ensure the manufacturer can accommodate your requests. -

What are the typical minimum order quantities (MOQs) for fiberglass statues?

Minimum order quantities can vary significantly among fiberglass statue manufacturers. Some may have low MOQs for custom pieces, while others might require larger orders to justify production costs. When sourcing suppliers, clarify their MOQ policies upfront. If you’re looking for a small quantity, consider manufacturers that specialize in custom projects or those that offer stock designs. Negotiating terms can also be possible, especially if you plan to establish a long-term partnership. -

What payment terms should I expect when ordering fiberglass statues internationally?

Payment terms can differ widely based on the manufacturer and the agreement reached. Common practices include a deposit upfront (usually 30-50%) and the balance due before shipment. Some manufacturers may offer flexible terms, such as payment upon delivery or through letters of credit, particularly for international transactions. Discuss payment methods, currency options, and any potential fees associated with international payments to avoid surprises. -

How can I effectively communicate my requirements to a fiberglass statue manufacturer?

Effective communication is key to a successful partnership with a fiberglass statue manufacturer. Start by providing detailed specifications, including dimensions, design concepts, and any unique features. Visual aids like sketches, photos, or CAD drawings can enhance understanding. Regular updates and feedback during the design and production phases are essential to ensure the project stays aligned with your vision. Establishing a point of contact can streamline communication and facilitate quick resolutions to any issues that arise. -

What logistics considerations should I be aware of when importing fiberglass statues?

When importing fiberglass statues, consider logistics such as shipping methods, customs duties, and potential tariffs. Working with a freight forwarder can help navigate international shipping and ensure compliance with local regulations. Be aware of the shipping timeline, as customs clearance can sometimes cause delays. Additionally, discuss packaging with the manufacturer to minimize damage during transit, and verify that insurance options are available for high-value shipments. -

What are the most common uses for fiberglass statues in various industries?

Fiberglass statues are versatile and find applications across multiple industries. In tourism, they serve as iconic landmarks or promotional displays. Retailers often use them as eye-catching advertising tools or mascots to attract customers. The entertainment industry incorporates fiberglass statues in theme parks and movie sets. Additionally, they are used in public art projects to enhance community engagement. Understanding your industry’s specific needs can help you select the right type of fiberglass statue. -

How can I assess a fiberglass statue manufacturer’s reputation and reliability?

To assess a manufacturer’s reputation, start by researching customer reviews and testimonials. Check for case studies or portfolios showcasing previous projects, particularly those similar to your requirements. Engaging with industry forums or trade associations can provide insights into the manufacturer’s standing. Additionally, consider reaching out to past clients for direct feedback on their experiences, including aspects like quality, communication, and adherence to deadlines. A reputable manufacturer will be transparent and willing to provide references.

Top 7 Fiberglass Statue Manufacturers Manufacturers & Suppliers List

1. Fiberstock – Custom Fiberglass Statues

ドメイン fiberstock.com

登録:1999年(26年)

はじめに Custom fiberglass statues, ability to create new models, custom painting options, custom designs available, alterations to existing products, detailed personal artwork options, collaboration with local artists for unique pieces, fundraising opportunities for cities or charitable organizations.

2. Fast Fiberglass – Custom Statues & Attractions

ドメイン ファストファイバーグラス・ドットコム

登録:2020年(5年間)

はじめに Custom fiberglass statues, sculptures, water slides, sprays, fountains, and features. Premier manufacturer of fiberglass statues and roadside attractions. Hand-crafted fiberglass creations including giant apples, pumpkins, cows, and themed water slides. Designed to withstand rigorous use and weather for decades with little maintenance. Offers a unique selection of themed water features. Home of TH…

3. Co-Arts Innovation – Custom Fiberglass Sculptures

ドメイン coartsinnovation.com

登録:2017年(8年目)

はじめに Co-Arts Innovation specializes in high-quality, custom fiberglass sculptures tailored to client specifications. Key features include:

– Custom Design Services: Unique sculptures based on client specifications, including modern art and lifelike animal figures.

– High-Quality Materials: UV-resistant, waterproof, and durable for indoor and outdoor use.

– Skilled Craftsmanship: Detailed and precise…

4. Demeng Toy – Custom Fiberglass Sculptures

ドメイン demengtoy.com

登録:2019年(6年)

はじめに Demeng Toy is a professional manufacturer of custom fiberglass sculptures, specializing in life-size statues. They have an independent fiberglass statue factory and a professional 3D modeling team. Their fiberglass art is used in theme parks, shopping malls, gardens, and public art installations. The manufacturing process involves 3D modeling, foam carving, mold fabrication, sculpture formation, d…

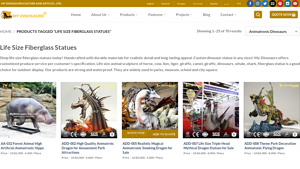

5. Mydinosaurs – Life Size Fiberglass Dinosaur Statues

ドメイン ミディノサウルス・ドットコム

登録:2013年(12年)

はじめに Life size fiberglass statues handcrafted with durable materials for realistic detail and long-lasting appeal. Custom dinosaur statues available in any size. Life size animal sculptures include horse, cow, lion, tiger, giraffe, camel, dinosaurs, whale, and shark. Products are strong and waterproof, suitable for outdoor display in parks, museums, schools, and city squares.

6. FRP Sculpture – Giant Fiberglass Statues

ドメイン frpsculpture.com

登録:2020年(5年間)

はじめに Giant Fiberglass Statues for Sale, Custom Large Outdoor Sculptures Manufacturer, Lightweight but Strong, Weather and Corrosion Resistance, Flexible Customization, Cost-Effective for Large-Scale Production, Types of Statues: Giant Animal Statues (Dinosaur, Lions, Tigers, Horses, Elephants), Oversized Human Sculptures (Historical, Cartoon, Sports), Abstract and Contemporary Sculptures (Geometric, Co…

7. Akin Sculpture – Fiberglass Sculptures

ドメイン akingsculpture.com

登録:2021年(4年間)

はじめに Fiberglass sculptures are lightweight, cost-effective, and durable, featuring characteristics such as moisture-proof insulation, impact resistance, and long-term color retention. They are made by hand using polyester resin and fiberglass, ensuring one-time molding without cracks, smooth surfaces, and rounded corners. The thickness of these sculptures is more than 5mm. Notable products include cart…

Strategic Sourcing Conclusion and Outlook for fiberglass statue manufacturers

In conclusion, strategic sourcing within the fiberglass statue manufacturing sector presents a wealth of opportunities for international B2B buyers. By prioritizing suppliers who demonstrate not only creativity and innovation but also reliability and quality, businesses can enhance their brand visibility and appeal through unique, custom designs. Key considerations include the manufacturer’s ability to deliver tailored solutions, maintain high standards of craftsmanship, and adhere to timelines, all of which are crucial for successful project execution.

Moreover, engaging with manufacturers that prioritize sustainable practices can align with corporate social responsibility goals, making them more attractive partners. As the demand for public art projects and themed displays continues to grow globally, particularly in regions like Africa, South America, the Middle East, and Europe, now is the opportune moment to invest in high-quality fiberglass sculptures.

Illustrative image related to fiberglass statue manufacturers

We encourage B2B buyers to explore partnerships with reputable fiberglass statue manufacturers to leverage their creativity and expertise. By doing so, you can elevate your marketing strategies, enhance community engagement, and ultimately drive business growth in a competitive landscape.

重要な免責事項および利用規約

⚠️ 重要な免責事項

メーカー、技術仕様、市場分析に関する内容を含め、本ガイドラインで提供される情報は、情報提供と教育目的のみのものです。専門的な調達アドバイス、財務アドバイス、または法的アドバイスを提供するものではありません。

情報の正確性、最新性には万全を期していますが、誤謬、脱漏、古い情報については責任を負いかねます。市場の状況、企業の詳細、技術水準は変更される場合があります。

B2Bバイヤーは、独自の徹底的なデューデリジェンスを行う必要がある。 購入を決定する前に。これには、サプライヤーに直接問い合わせること、認定を確認すること、サンプルを請求すること、専門家に相談することなどが含まれる。本ガイドブックに記載された情報を信頼するリスクは、読者が負うものとします。