Introduction: Navigating the Global Market for 3d sculpture

Navigating the complex landscape of the global market for 3D sculpture presents a unique challenge for international B2B buyers seeking to source innovative and high-quality art pieces. The ability to effectively source 3D sculptures that align with specific business needs—be it for marketing displays, corporate gifts, or interior design—can significantly impact a brand’s image and customer engagement. This guide serves as a comprehensive resource, covering various types of 3D sculptures, their diverse applications, strategies for supplier vetting, and insights into cost considerations.

As businesses in regions such as Africa, South America, the Middle East, and Europe (including Nigeria and Vietnam) expand their artistic horizons, understanding the intricacies of the 3D sculpture market becomes crucial. This guide empowers buyers to make informed purchasing decisions by providing actionable insights into current trends, sourcing strategies, and quality assurance measures. By equipping decision-makers with knowledge about material selection, design trends, and supplier reliability, this resource aims to streamline the procurement process and enhance the overall buying experience. Whether you are looking for custom designs or ready-to-print models, navigating this market with confidence can lead to impactful artistic investments that resonate with your audience.

目次

- Top 4 3D Sculpture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 3d sculpture

- Understanding 3d sculpture Types and Variations

- Key Industrial Applications of 3d sculpture

- 3 Common User Pain Points for ‘3d sculpture’ & Their Solutions

- Strategic Material Selection Guide for 3d sculpture

- In-depth Look: Manufacturing Processes and Quality Assurance for 3d sculpture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d sculpture’

- Comprehensive Cost and Pricing Analysis for 3d sculpture Sourcing

- Alternatives Analysis: Comparing 3d sculpture With Other Solutions

- Essential Technical Properties and Trade Terminology for 3d sculpture

- Navigating Market Dynamics and Sourcing Trends in the 3d sculpture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 3d sculpture

- Strategic Sourcing Conclusion and Outlook for 3d sculpture

- 重要な免責事項および利用規約

Understanding 3d sculpture Types and Variations

| タイプ名 | 主な特徴 | 主なB2Bアプリケーション | バイヤーのための簡単な長所と短所 |

|---|---|---|---|

| 具象彫刻 | Represents human or animal forms in realistic detail | Art galleries, museums, corporate decor | 長所だ: High emotional impact; 短所だ: Often requires significant investment. |

| 抽象彫刻 | Focuses on shapes and forms rather than representation | Modern art installations, branding | 長所だ: 独特の美的魅力; 短所だ: すべての観客に響くとは限らない。 |

| キネティック・スカルプチャー | Incorporates movement, either mechanically or naturally | Outdoor art displays, exhibitions | 長所だ: 魅力的でダイナミック; 短所だ: メンテナンスは複雑だ。 |

| レリーフ彫刻 | Partially three-dimensional, often wall-mounted | Interior design, signage | 長所だ: スペース効率が良い; 短所だ: Limited visual impact from certain angles. |

| デジタル彫刻 | Created using software and often 3D printed | Prototyping, product design | 長所だ: High precision and customization; 短所だ: Initial software costs can be high. |

具象彫刻の特徴とは?

Figurative sculptures are designed to depict recognizable forms, typically human figures or animals. They are crafted with meticulous attention to detail, making them ideal for settings such as art galleries, museums, and corporate environments. When purchasing figurative sculptures, B2B buyers should consider the artist’s reputation, the material used, and the piece’s emotional resonance, as these factors can significantly impact value and appeal.

抽象彫刻は他の彫刻とどう違うのか?

Abstract sculptures prioritize form and color over realistic representation, allowing for a wide range of interpretations. This type of sculpture is commonly used in modern art installations and branding efforts, where the goal is to evoke thought and conversation. B2B buyers should evaluate the artistic vision and how well the piece aligns with their brand identity, as abstract sculptures can create a powerful statement but may not appeal to all audiences.

What Are the Key Features of Kinetic Sculpture?

Kinetic sculptures are distinguished by their ability to move, either through mechanical means or natural forces like wind. These pieces are often used in outdoor art displays and exhibitions, captivating viewers with their dynamic nature. Buyers should consider the mechanics involved and the potential maintenance required when investing in kinetic sculptures, as the complexity can affect long-term costs and functionality.

Why Choose Relief Sculpture for Interior Design?

Relief sculptures are partially three-dimensional, often mounted on walls, making them an excellent choice for interior spaces where floor space is limited. They are commonly used in decorative applications and signage. B2B buyers should assess the visual impact of relief sculptures from various angles and consider how they complement existing decor, as their effectiveness can vary based on placement and lighting.

How Do Digital Sculptures Fit into Modern Design?

Digital sculptures are created using advanced software and can be 3D printed for physical representation. This allows for high precision and customization, making them ideal for prototyping and product design. B2B buyers should weigh the advantages of technological integration and the potential for rapid iteration against the initial costs of software and printing technology, which can be significant but ultimately beneficial for innovation.

Key Industrial Applications of 3d sculpture

| 業界/セクター | Specific Application of 3D Sculpture | ビジネスにとっての価値/利益 | このアプリケーションにおける主な調達上の考慮事項 |

|---|---|---|---|

| 建築 | Architectural Models | Enhances client presentations and project visualization | Consider precision, material quality, and scalability of models. |

| Entertainment | Character Design and Prototyping | Accelerates game and film production with rapid prototyping | Evaluate design fidelity, turnaround time, and licensing rights. |

| ヘルスケア | Medical Models for Training and Simulation | Improves training outcomes and patient understanding | Focus on anatomical accuracy, material biocompatibility, and customizability. |

| Art and Design | Custom Art Installations | Differentiates brand identity and enhances aesthetic appeal | Assess artist collaboration, uniqueness, and production techniques. |

| 製造業 | Tooling and Molds | Reduces lead time and costs in product development | Prioritize durability, precision, and compatibility with existing systems. |

How is 3D Sculpture Transforming the Architecture Industry?

In architecture, 3D sculpture plays a pivotal role in creating detailed architectural models that provide a tangible representation of designs. These models allow architects to present their visions to clients, facilitating better communication and understanding. By employing 3D sculptures, firms can showcase intricate details that digital images often fail to convey, ultimately leading to increased client satisfaction. Buyers should consider sourcing from providers who offer high precision and use durable materials to ensure the models can withstand multiple presentations and revisions.

What Role Does 3D Sculpture Play in Entertainment?

The entertainment industry leverages 3D sculpture for character design and prototyping, particularly in video games and films. This technology allows creators to quickly produce lifelike models that can be used for animation or visual effects, streamlining the production process. Rapid prototyping reduces the time from concept to execution, enabling studios to remain competitive. International buyers must evaluate design fidelity and turnaround times, as well as the ownership rights associated with the characters developed.

Why is 3D Sculpture Important in Healthcare?

In healthcare, 3D sculptures are utilized to create medical models for training and simulation purposes. These models enhance the educational experience for medical professionals, allowing them to practice procedures on accurate representations of human anatomy. This not only improves training outcomes but also helps patients understand their conditions better through visual aids. Buyers should prioritize sourcing from manufacturers who ensure anatomical accuracy and use biocompatible materials, especially when the models are intended for patient interaction.

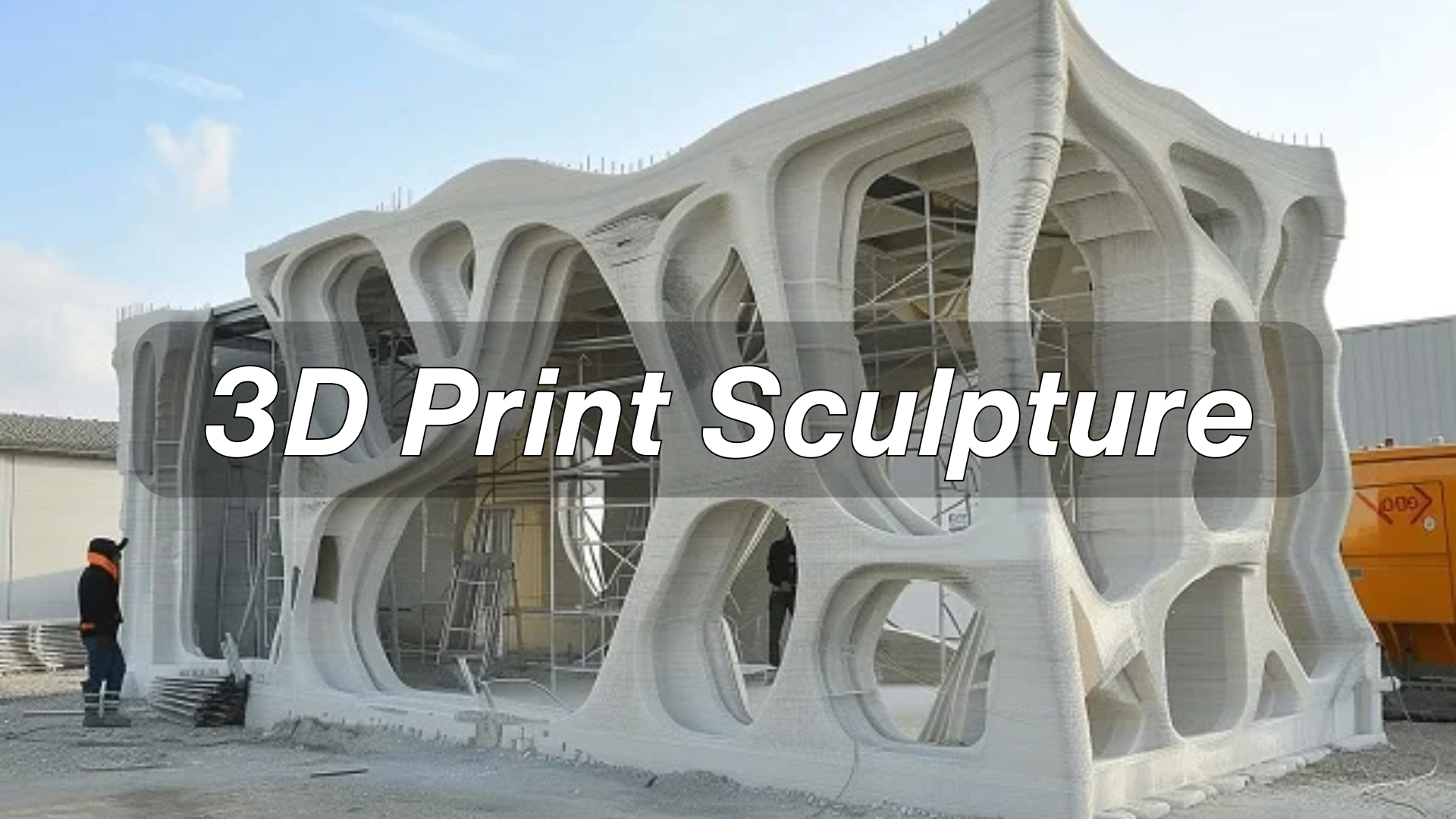

Illustrative image related to 3d sculpture

How Can 3D Sculpture Enhance Art and Design?

The art and design sector utilizes 3D sculpture to create custom art installations that can significantly enhance brand identity. By employing unique sculptures, businesses can differentiate themselves in a crowded market and improve the aesthetic appeal of their spaces. This application allows for a high degree of customization, catering to specific themes or messages a brand wishes to convey. Buyers should focus on collaborating with artists who can deliver unique designs and consider the production techniques that align with their vision.

What Advantages Does 3D Sculpture Offer in Manufacturing?

In manufacturing, 3D sculptures are crucial for creating tooling and molds, significantly reducing lead times and costs in product development. By using additive manufacturing techniques, companies can produce highly detailed and precise molds that are essential for efficient production processes. This application allows manufacturers to iterate designs quickly, adapting to market demands without extensive downtime. Buyers should prioritize sourcing durable and precise molds that can integrate seamlessly with existing manufacturing systems to maximize efficiency.

3 Common User Pain Points for ‘3d sculpture’ & Their Solutions

Scenario 1: Navigating Quality and Consistency in 3D Sculpture Production

問題だ:

B2B buyers often face the challenge of ensuring the quality and consistency of 3D sculptures, especially when sourcing from multiple suppliers across different regions. Inconsistent materials, varying printing technologies, and differing artistic interpretations can lead to a final product that does not meet specifications or expectations. For example, a buyer may order a series of sculptures for a corporate event, only to find that the colors, textures, and overall finish vary significantly between pieces, undermining the brand’s image.

解決策

To mitigate quality issues, B2B buyers should establish clear specifications and quality standards before placing orders. This includes detailed descriptions of materials, finishes, and dimensions. Utilizing a centralized digital platform to communicate these specifications can ensure all parties are aligned. Furthermore, it’s beneficial to request samples before committing to larger orders. By evaluating these prototypes, buyers can assess the quality and consistency of the sculptures. Collaborating closely with suppliers who use standardized materials and technologies can also help maintain uniformity across production runs.

Scenario 2: Overcoming Limited Design Flexibility in Custom 3D Sculptures

問題だ:

B2B buyers often encounter limitations when trying to customize 3D sculptures to align with specific branding or thematic requirements. Many suppliers may offer a limited range of existing designs or lack the technological capability to produce bespoke sculptures that meet unique specifications. This can stifle creativity and prevent businesses from fully expressing their brand identity through art, leading to missed opportunities in marketing and engagement.

Illustrative image related to 3d sculpture

解決策

To enhance design flexibility, buyers should prioritize partnerships with suppliers who offer advanced 3D modeling software and customization options. Suppliers that utilize cloud-based design tools, such as SOLIDWORKS 3D Sculptor, enable buyers to engage in the design process actively. This allows for real-time modifications and adjustments, ensuring the final product reflects the desired vision. Additionally, investing in a collaborative approach, where buyers can work directly with designers, can lead to more innovative outcomes and a stronger alignment with branding goals.

Scenario 3: Managing Costs and Budget Constraints in 3D Sculpture Projects

問題だ:

Budget constraints are a common concern for B2B buyers involved in 3D sculpture projects. Unexpected costs can arise from changes in material prices, shipping fees, or the need for additional revisions, leading to project overruns. This situation can be particularly problematic for organizations in emerging markets, where tight budgets are the norm and any financial misstep can have significant repercussions.

解決策

To manage costs effectively, buyers should develop a comprehensive budget that includes not just the initial costs of the sculptures but also potential contingencies. Engaging in transparent discussions with suppliers about pricing structures can help clarify any hidden costs. It’s also advantageous to explore bulk order discounts or long-term contracts with suppliers to lock in prices. Furthermore, using cost-effective materials without compromising on quality can help keep expenses in check. Conducting regular reviews of project budgets throughout the production process allows for timely adjustments and better financial oversight.

Strategic Material Selection Guide for 3d sculpture

What Are the Key Properties of Common Materials Used in 3D Sculpture?

In the realm of 3D sculpture, selecting the right material is crucial for achieving the desired aesthetic and functional outcomes. Here, we analyze four common materials used in 3D sculpture: PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), resin, and metal. Each material has distinct properties that influence its performance, cost, and suitability for various applications.

How Does PLA Perform in 3D Sculpture Applications?

PLA is a biodegradable thermoplastic derived from renewable resources like cornstarch. Its key properties include a low melting temperature (around 180-220°C), which makes it easy to print, and good dimensional stability. PLA is also known for its vibrant color options and smooth finish.

Illustrative image related to 3d sculpture

長所だ: PLA is user-friendly, making it ideal for beginners. It is also environmentally friendly and produces minimal warping during printing, which enhances its usability for intricate designs.

短所だ: Its lower temperature resistance (around 60°C) limits its use in high-heat applications. Additionally, PLA can be brittle, making it less durable for sculptures that require handling or outdoor exposure.

For international buyers, especially in regions like Africa and South America, compliance with environmental regulations may favor PLA. However, they should be aware of local availability and sourcing challenges.

What Are the Advantages and Disadvantages of Using ABS?

ABS is a popular thermoplastic known for its strength and impact resistance. It has a higher melting temperature (around 220-250°C) compared to PLA, which allows for more durable sculptures.

長所だ: ABS is highly durable and can withstand higher temperatures, making it suitable for functional sculptures. It also has good post-processing capabilities, allowing for sanding and painting.

短所だ: The material emits fumes during printing, requiring adequate ventilation. Additionally, ABS can warp if not printed under controlled conditions, which may complicate the manufacturing process.

For B2B buyers in the Middle East and Europe, understanding compliance with health and safety regulations regarding emissions is crucial. Buyers should also consider the cost of additional equipment for ventilation and temperature control.

Why Choose Resin for Detailed 3D Sculptures?

Resin is favored for its ability to produce high-resolution prints with intricate details. It typically cures under UV light and has a lower viscosity, allowing for smoother finishes.

長所だ: Resin offers exceptional detail and surface finish, making it ideal for artistic sculptures. It is also less prone to warping compared to thermoplastics.

短所だ: The printing process can be more complex, requiring post-curing and handling of toxic materials. Resin can also be more expensive than thermoplastics.

Illustrative image related to 3d sculpture

For international buyers, particularly in Europe, compliance with chemical safety regulations (like REACH) is essential. Buyers should also consider the availability of resin types that meet local standards.

What Are the Benefits and Limitations of Metal in 3D Sculpture?

Metal 3D printing, often using techniques like DMLS (Direct Metal Laser Sintering), allows for the creation of robust and highly durable sculptures. Metals like aluminum and stainless steel are commonly used.

長所だ: Metal sculptures are incredibly durable and can withstand harsh environmental conditions. They also provide a unique aesthetic that is hard to replicate with other materials.

短所だ: Metal 3D printing is often more expensive and requires specialized equipment and expertise. The post-processing steps can also be time-consuming.

For B2B buyers in Africa and South America, the high cost and technical requirements of metal printing may be prohibitive. Understanding local infrastructure for metal processing and compliance with industry standards is vital for successful procurement.

Summary Table of Material Selection for 3D Sculpture

| 素材 | Typical Use Case for 3D Sculpture | 主な利点 | 主な欠点/制限 | 相対コスト(低/中/高) |

|---|---|---|---|---|

| PLA | Decorative sculptures and prototypes | Environmentally friendly and easy to print | Brittle and low heat resistance | 低い |

| ABS | Functional sculptures and prototypes | Durable and impact-resistant | Emits fumes and prone to warping | ミディアム |

| 樹脂 | High-detail artistic sculptures | Exceptional detail and smooth finish | Complex printing process and toxic materials | 高い |

| メタル | Robust and durable sculptures | Highly durable and unique aesthetic | Expensive and requires specialized equipment | 高い |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of common materials used in 3D sculpture. Understanding these factors can significantly influence the decision-making process in various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d sculpture

What Are the Key Stages in the Manufacturing Process of 3D Sculptures?

The manufacturing process for 3D sculptures involves several critical stages, ensuring that the final product meets both artistic and quality standards. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for 3D Sculpture Production?

Material preparation is the first step in the production of 3D sculptures. This stage involves selecting the appropriate materials, such as plastics, resins, or metals, based on the desired aesthetic and functional characteristics of the sculpture. For instance, thermoplastics are often favored for their versatility and ease of printing, while metal powders are used in metal 3D printing processes.

Once the materials are selected, they undergo pre-processing, which may include drying, grinding, or mixing with additives to enhance their properties. For example, adding colorants or stabilizers can improve the durability and visual appeal of the sculpture. This preparation is critical, as any defects at this stage can propagate through the manufacturing process, affecting the final product’s quality.

What Techniques Are Commonly Used in the Forming Stage?

The forming stage encompasses various techniques to create the sculpture’s shape. The most popular methods include:

Illustrative image related to 3d sculpture

-

Fused Deposition Modeling (FDM): This technique uses a continuous filament of thermoplastic material, which is heated and extruded to build the sculpture layer by layer. It’s widely used for its cost-effectiveness and ease of use.

-

Stereolithography (SLA): SLA employs a laser to cure liquid resin into solid form. This method is known for its high precision and is ideal for intricate designs.

-

Selective Laser Sintering (SLS): In this process, powdered material is fused together using a laser. SLS allows for the creation of complex geometries and is suitable for materials like nylon and metal powders.

Each of these techniques has its advantages and is selected based on the project requirements, including complexity, desired finish, and material properties.

彫刻はどのように組み立てられ、仕上げられるのか?

The assembly stage is crucial for sculptures that consist of multiple components. This process may involve gluing, welding, or mechanical fastening, depending on the materials used and the design of the sculpture. Attention to detail is essential during this phase, as misalignment can compromise the sculpture’s aesthetic and structural integrity.

Finishing is the final step, where the sculpture undergoes various treatments to enhance its appearance and durability. Techniques may include sanding, painting, coating, and polishing. For instance, applying a protective coating can enhance the sculpture’s longevity, particularly for outdoor installations exposed to the elements.

Illustrative image related to 3d sculpture

What Quality Assurance Measures Are Essential for 3D Sculptures?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the sculptures meet both international standards and client specifications. Key components of QA include adherence to international standards such as ISO 9001, which focuses on effective quality management systems.

B2Bバイヤーが知っておくべき国際規格とは?

For B2B buyers, understanding relevant international standards is crucial in verifying the quality of 3D sculptures. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system, emphasizing continuous improvement and customer satisfaction. In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold within the European market and API (American Petroleum Institute) standards for sculptures used in industrial applications may also apply.

How Are Quality Control Checkpoints Structured?

Quality control checkpoints are established throughout the manufacturing process to identify and rectify any defects early. Common checkpoints include:

-

受入品質管理(IQC): This initial phase involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

インプロセス品質管理(IPQC): Ongoing inspections during the manufacturing process help catch defects early, allowing for timely adjustments.

-

最終品質管理(FQC): This final assessment ensures that the completed sculpture meets all quality standards before shipment.

These checkpoints serve as a framework for maintaining quality and can be customized based on specific project requirements.

What Testing Methods Are Used to Ensure Quality?

Various testing methods are employed to assess the quality of 3D sculptures, ensuring they meet required specifications. Common testing methods include:

Illustrative image related to 3d sculpture

-

Dimensional Inspection: Verifying that the sculpture adheres to specified dimensions using calipers or 3D scanning technology.

-

材料試験: Assessing the mechanical properties of the material, such as tensile strength or impact resistance, through standardized tests.

-

目視検査: A thorough visual assessment is conducted to identify any surface defects or inconsistencies in finish.

These testing methods provide valuable insights into the sculpture’s quality and longevity.

B2Bバイヤーはサプライヤーの品質管理をどのように検証できるか?

B2B buyers should take proactive steps to verify a supplier’s quality control processes. This can be achieved through:

-

サプライヤー監査: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and adherence to industry standards.

-

品質レポート: Requesting detailed quality reports, including inspection results and testing data, can provide insight into the supplier’s commitment to quality.

-

第三者検査: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control processes and compliance with standards.

海外バイヤーにとっての品質管理の難しさとは?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Cultural differences, varying standards, and logistical challenges can impact quality assurance processes. Buyers should be aware of local regulations and standards that may differ from international norms.

Additionally, language barriers and time zone differences can complicate communication with suppliers. Establishing clear lines of communication and ensuring that all parties understand quality expectations will help mitigate these challenges.

Illustrative image related to 3d sculpture

In conclusion, the manufacturing processes and quality assurance for 3D sculptures are multifaceted and require careful consideration at each stage. By understanding these processes, B2B buyers can make informed decisions, ensuring they receive high-quality products that meet their specifications and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d sculpture’

In the competitive landscape of 3D sculpture procurement, a structured approach is essential for B2B buyers to ensure they obtain quality products that meet their specific needs. This guide provides a checklist to streamline the sourcing process, enabling buyers to make informed decisions when acquiring 3D sculptures.

ステップ1: 技術仕様の定義

Establishing clear technical specifications is the foundation of your sourcing process. Consider the size, material, complexity, and intended use of the sculptures. Specifics such as whether the sculptures will be used for display, promotional purposes, or functional art can significantly influence your choice of suppliers.

- 素材の選択: Decide if you need sculptures made from plastics, metals, or other materials, as this will affect durability and cost.

- Scale and Size: Determine the dimensions required for your space to avoid issues with fit and aesthetic appeal.

ステップ2: サプライヤー候補の調査

Conduct thorough research to identify suppliers who specialize in 3D sculptures. Look for companies with a proven track record in your industry or region, as they will better understand your unique needs.

Illustrative image related to 3d sculpture

- サプライヤーの評判 Check online reviews, testimonials, and case studies to gauge their reliability and quality of work.

- Portfolio Assessment: Review their previous projects to assess whether their style aligns with your vision.

ステップ3: サプライヤーの能力を評価する

契約する前に、サプライヤーを徹底的に吟味することが重要です。似たような業界や地域のバイヤーに、会社概要、ケーススタディ、推薦状を依頼しましょう。ウェブサイトを鵜呑みにしないこと。

- 生産能力: Ensure the supplier can meet your order volume within your required timeline.

- Technological Proficiency: Inquire about the 3D printing technologies and techniques they use, as this can impact the quality and detail of the sculptures.

ステップ4: サンプルまたはプロトタイプのリクエスト

Obtaining samples or prototypes is a critical step in assessing the quality of a supplier’s work. This allows you to evaluate craftsmanship and material quality firsthand.

- 品質保証: Inspect samples for detail, finish, and durability to ensure they meet your standards.

- フィードバック・ループ: Use the opportunity to provide feedback on prototypes, which can help refine the final product.

ステップ5: サプライヤーの認証とコンプライアンスの確認

Ensure that your chosen supplier complies with industry standards and certifications. This is particularly important for international transactions, where regulations may vary.

- 品質認証: Look for ISO certifications or other quality assurance standards that indicate a commitment to excellence.

- サステナビリティの実践: If relevant, check whether the supplier follows sustainable practices in sourcing materials and production.

ステップ6: 条件と価格の交渉

Once you’ve narrowed down potential suppliers, engage in negotiations to finalize pricing, delivery terms, and payment methods. This is your opportunity to ensure you receive the best value for your investment.

- 透明な価格設定: Request a detailed breakdown of costs, including production, shipping, and any additional fees.

- Contractual Clarity: Ensure that all terms are clearly outlined in a contract to avoid misunderstandings later.

ステップ7: コミュニケーション・プランの策定

Effective communication is vital throughout the sourcing process. Establish a clear communication plan with your chosen supplier to facilitate updates and address any issues that may arise.

- Regular Check-Ins: Schedule regular updates to monitor progress and address any concerns promptly.

- Point of Contact: Designate a primary contact person on both sides to streamline communication and decision-making.

By following this checklist, B2B buyers can navigate the complexities of sourcing 3D sculptures more effectively, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for 3d sculpture Sourcing

The cost structure and pricing for sourcing 3D sculptures can vary significantly based on multiple factors. Understanding these components is essential for B2B buyers aiming to optimize their procurement strategies, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in 3D Sculpture Production?

-

材料: The choice of materials heavily influences the final cost. Common materials for 3D sculptures include plastics, resins, metal, and even biodegradable options. Each material has its price point, and while high-quality materials might incur higher upfront costs, they can enhance the sculpture’s durability and aesthetic appeal.

-

労働: Labor costs can differ based on geographical location and the skill level of the artisans involved. In regions where labor is more affordable, such as parts of Africa and South America, buyers may find significant savings. However, it’s essential to consider the trade-off between cost and craftsmanship quality.

-

製造間接費: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturers often manage these costs effectively, which can translate to better pricing for buyers.

-

工具: Tooling refers to the expenses incurred in creating molds and other tools necessary for production. This is particularly important for custom designs, where upfront tooling costs can be significant but are amortized over larger production runs.

-

品質管理(QC): Ensuring the sculptures meet specific quality standards may involve additional QC costs. This is particularly critical for international buyers who may require certifications or adherence to specific industry standards.

-

物流: Shipping and handling costs are crucial, especially for international transactions. Factors such as distance, transportation mode, and packaging requirements can impact overall logistics costs.

-

マージン: The supplier’s profit margin is included in the final pricing. This can vary significantly based on the supplier’s market positioning, brand value, and competition.

How Do Price Influencers Affect 3D Sculpture Sourcing?

-

数量/MOQ (最小注文数量): Pricing often decreases with larger orders due to economies of scale. Buyers should evaluate their needs and consider bulk purchasing to negotiate better rates.

-

仕様とカスタマイズ: Custom sculptures or those with unique specifications typically cost more. Buyers should weigh the need for customization against standard offerings that might be more cost-effective.

-

材料と品質認証: Higher quality materials and certifications can drive up costs. Understanding the balance between desired quality and budget constraints is vital for international buyers.

-

サプライヤー要因: The reliability and reputation of the supplier can influence pricing. Established suppliers with proven track records may charge a premium but could provide better assurance of quality and delivery timelines.

-

インコタームズ: Understanding shipping terms is crucial for cost management. Different Incoterms (e.g., FOB, CIF) affect who bears the cost and risk during transport, impacting the total landed cost of the sculptures.

What Are Some Buyer Tips for Cost-Efficient 3D Sculpture Sourcing?

-

交渉: Always negotiate prices and terms. Building a relationship with suppliers can lead to better deals and improved service.

-

Cost-Efficiency Considerations: Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential resale value. Sometimes, cheaper options may lead to higher long-term costs.

-

海外バイヤーのための価格設定のニュアンス: Be aware of currency fluctuations and import duties that can affect pricing. Buyers from regions like Africa and South America should also consider local economic conditions that may impact supplier pricing strategies.

In conclusion, sourcing 3D sculptures involves navigating a complex landscape of costs and pricing factors. By understanding these elements and leveraging effective negotiation strategies, B2B buyers can optimize their procurement processes and achieve better value for their investments. Always remember that indicative prices can vary widely based on the factors discussed, so careful planning and research are essential.

Alternatives Analysis: Comparing 3d sculpture With Other Solutions

Understanding Alternatives to 3D Sculpture for B2B Buyers

In the realm of artistic and functional design, 3D sculpture presents a unique way to create visually striking objects. However, various alternative methods and technologies can achieve similar goals in different contexts. Understanding these alternatives allows businesses to make informed decisions based on their specific needs, budget, and project requirements.

Comparison of 3D Sculpture and Alternative Solutions

| 比較の側面 | 3D Sculpture | Digital Sculpting Software | Traditional Sculpting Techniques |

|---|---|---|---|

| パフォーマンス | High-quality, detailed outputs | Excellent for rapid prototyping | Labor-intensive, but highly artistic |

| コスト | Moderate to high (materials & time) | Low to moderate (software fees) | Variable (material costs, tools) |

| 実施しやすさ | 熟練した職人が必要 | User-friendly for trained users | Requires extensive training |

| メンテナンス | Minimal (once completed) | Regular software updates needed | Ongoing tool and material upkeep |

| ベスト・ユースケース | Art installations, unique designs | Prototyping, animation, gaming | Fine art, custom projects |

What Are the Pros and Cons of Digital Sculpting Software?

Digital sculpting software, such as ZBrush or Blender, offers a modern approach to creating three-dimensional models. The primary advantage of this method is its ability to produce high-fidelity designs quickly, making it ideal for rapid prototyping and iterative design processes. Additionally, it allows for easy modifications and iterations without the physical constraints of traditional materials. However, it may lack the tactile experience and unique imperfections that come with handcrafted sculptures, which some clients and artists highly value.

How Do Traditional Sculpting Techniques Compare?

Traditional sculpting techniques involve working with materials such as clay, stone, or metal to create tangible art pieces. This method is revered for its artistic expression and the physical connection an artist has with their medium. The craftsmanship involved often results in unique, one-of-a-kind pieces that can hold significant artistic value. However, traditional methods can be labor-intensive, time-consuming, and may require a higher level of expertise. Material costs can also vary widely depending on the medium chosen.

Illustrative image related to 3d sculpture

結論B2Bバイヤーはどのように適切なソリューションを選択できるか?

When selecting between 3D sculpture and its alternatives, B2B buyers should consider their specific objectives, budget constraints, and the desired outcome of their projects. For businesses looking to create unique, artistic installations, 3D sculpture remains a strong contender. Conversely, if rapid prototyping or digital assets for gaming and animation are the goals, digital sculpting software may provide a more efficient solution. Traditional techniques may be more suited for fine art and custom projects requiring a human touch. Ultimately, the best choice will align with the buyer’s strategic vision and operational capabilities.

Essential Technical Properties and Trade Terminology for 3d sculpture

What Are the Key Technical Properties of 3D Sculpture?

Understanding the technical properties of 3D sculpture is crucial for B2B buyers, especially when selecting materials and processes that meet their project requirements. Here are some essential specifications:

素材グレード

Material grade refers to the quality and composition of the materials used in 3D sculpture, such as plastics, metals, or resins. For example, high-grade materials like ABS or PLA are often used in 3D printing for their durability and ease of use. Choosing the right material grade ensures that the final product meets quality standards and performs well in its intended application.

寛容

Tolerance is the allowable variation in dimensions of a sculpture. In 3D sculpture, tight tolerances (often in millimeters) are important to ensure that parts fit together precisely, especially for complex models. For B2B buyers, understanding tolerance levels is vital to minimize rework and ensure that the final product aligns with design specifications.

Illustrative image related to 3d sculpture

表面仕上げ

Surface finish describes the texture and quality of a sculpture’s surface after printing or manufacturing. Common finishes include smooth, textured, or painted surfaces. A higher quality surface finish can significantly enhance the aesthetic appeal of a sculpture, which is particularly important for commercial displays or artistic installations.

Layer Height

Layer height is a critical parameter in 3D printing that refers to the thickness of each layer of material deposited during the printing process. Smaller layer heights typically result in higher resolution and detail, which is crucial for intricate designs. For B2B buyers, selecting the appropriate layer height can impact both the visual quality and the production time of the sculpture.

Print Speed

Print speed indicates how quickly a 3D printer can produce a sculpture. Faster print speeds can reduce production time, but may compromise detail and finish quality. Buyers should balance the need for speed with the required quality to meet project deadlines without sacrificing craftsmanship.

What Are Common Terms Used in the 3D Sculpture Industry?

Familiarity with industry terminology can facilitate smoother negotiations and clearer communication between buyers and suppliers. Here are several key terms to know:

OEM(相手先ブランド製造)

OEM refers to companies that produce parts or products that are then marketed by another company under its brand. In the context of 3D sculpture, an OEM might produce specific components or sculptures that are then sold by a retailer. Understanding OEM relationships can help buyers identify reliable partners for sourcing high-quality products.

MOQ(最小注文数量)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers looking to place bulk orders for sculptures. Knowing the MOQ can help businesses plan their budgets and inventory more effectively.

RFQ(見積依頼)

An RFQ is a document that buyers send to suppliers to request pricing and terms for a specific order. For buyers in the 3D sculpture market, issuing an RFQ can streamline the procurement process and ensure that they receive competitive pricing and terms from multiple suppliers.

インコタームズ(国際商業取引用語)

Incoterms are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international trade. For example, terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks during transport. Understanding Incoterms is essential for B2B transactions, especially when dealing with international suppliers.

CAD(コンピューター支援設計)

CAD refers to software used for creating precise drawings and technical illustrations of sculptures. CAD models serve as the blueprint for 3D printing and manufacturing processes. Buyers should be aware of how CAD files are used to streamline production and ensure accuracy in the final product.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, foster effective supplier relationships, and ultimately enhance their procurement strategies in the dynamic field of 3D sculpture.

Navigating Market Dynamics and Sourcing Trends in the 3d sculpture Sector

What Are the Key Trends Driving the 3D Sculpture Market?

The global 3D sculpture market is witnessing transformative shifts driven by technological advancements and evolving consumer preferences. Increased adoption of 3D printing technology has democratized access to sculpture creation, allowing artists and businesses to produce complex designs with reduced time and cost. This trend is particularly relevant for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where local artisans and businesses can leverage this technology to create culturally relevant pieces that resonate with their markets.

Illustrative image related to 3d sculpture

Emerging trends include the rise of customizable and personalized sculptures, driven by consumer demand for unique products. B2B buyers are increasingly looking for suppliers who can offer tailored solutions, aligning with specific branding or cultural themes. Additionally, the integration of augmented reality (AR) in the design process is gaining traction, enabling buyers to visualize sculptures in their intended environments before purchase. This technology enhances the customer experience, making it easier for buyers to make informed decisions.

Lastly, the market is experiencing a surge in online platforms dedicated to 3D sculpture sales, facilitating easier access for international buyers. These platforms not only provide a wide variety of designs but also enable collaboration among artists globally, creating a rich ecosystem for sourcing innovative sculptures.

How Is Sustainability and Ethical Sourcing Impacting the 3D Sculpture Industry?

Sustainability and ethical sourcing have become paramount in the 3D sculpture sector, as buyers increasingly prioritize environmental impact in their procurement processes. The production of sculptures, particularly those made from traditional materials like marble and metal, has raised concerns regarding resource depletion and environmental degradation. Consequently, there is a growing emphasis on sourcing materials that are renewable, recyclable, or biodegradable.

B2B buyers are seeking suppliers who adhere to ethical supply chain practices, ensuring that materials are sourced responsibly and that labor practices are fair and transparent. This is particularly crucial for businesses looking to enhance their corporate social responsibility (CSR) profiles. Certifications such as the Forest Stewardship Council (FSC) for wood products or the Global Recycled Standard (GRS) for recycled materials are becoming essential for suppliers aiming to attract conscientious buyers.

Moreover, the use of eco-friendly 3D printing materials, such as biodegradable filaments and recycled plastics, is on the rise. These innovations not only reduce the environmental footprint of sculpture production but also appeal to a growing segment of consumers who are environmentally conscious. As a result, B2B buyers are encouraged to align their sourcing strategies with sustainable practices, fostering a more responsible and future-proof business model.

What Is the Historical Context of 3D Sculpture in B2B Markets?

The evolution of 3D sculpture can be traced back to the early days of digital modeling and computer-aided design (CAD) in the late 20th century. Initially, 3D sculptures were primarily the domain of artists and designers with access to expensive software and hardware. However, the advent of affordable 3D printing technology in the 2010s revolutionized the industry, enabling a broader range of creators, including small businesses and individual artisans, to produce intricate sculptures.

As 3D printing technology became more accessible, the market expanded significantly, paving the way for diverse applications in various sectors, including art, architecture, and product design. This evolution has empowered B2B buyers to source unique sculptures that not only meet aesthetic demands but also align with their business objectives, enhancing brand identity and customer engagement. The historical trajectory of 3D sculpture underscores the importance of technological advancements in shaping market dynamics and sourcing strategies in today’s global economy.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d sculpture

-

How do I source high-quality 3D sculptures for my business needs?

To source high-quality 3D sculptures, start by identifying reputable suppliers with a strong portfolio showcasing their previous work. Utilize online platforms specializing in 3D models, and consider reaching out to local artists or studios to explore unique designs. Always request samples or prototypes to assess quality before making large purchases. Additionally, check for customer reviews and testimonials to ensure reliability and quality assurance. -

What are the benefits of custom 3D sculptures for my brand?

Custom 3D sculptures can significantly enhance your brand identity by providing unique, tailored designs that reflect your company’s values and aesthetics. They can be used for promotional events, as corporate gifts, or as decorative elements in office spaces. By incorporating your branding elements into the sculptures, you can create memorable experiences for clients and stakeholders, ultimately reinforcing brand recognition and loyalty. -

What is the typical minimum order quantity (MOQ) for 3D sculptures?

Minimum order quantities for 3D sculptures vary by supplier, but they generally range from 10 to 100 units. Factors influencing MOQ include the complexity of the design, production methods, and material costs. For smaller businesses, it’s advisable to discuss flexibility with suppliers, as some may accommodate smaller orders, especially for custom designs. Always clarify MOQs before placing an order to avoid unexpected costs. -

What payment terms should I expect when ordering 3D sculptures internationally?

Payment terms for international orders typically involve a deposit upfront, often between 30-50%, with the balance due upon delivery or prior to shipment. Some suppliers may offer payment through letters of credit, PayPal, or bank transfers, which can provide additional security. It’s essential to negotiate terms upfront and ensure they are documented in your purchase agreement to prevent misunderstandings. -

How can I ensure the quality of 3D sculptures I order?

To ensure quality, request detailed specifications and production samples before finalizing your order. Establish clear quality assurance protocols with your supplier, including inspection processes at various stages of production. Additionally, consider visiting the production facility if feasible, or utilize third-party quality inspection services to verify that the sculptures meet your standards before shipment. -

What logistics considerations should I be aware of when importing 3D sculptures?

When importing 3D sculptures, consider shipping methods, customs duties, and potential delays. Choose a reliable logistics partner experienced in handling art and fragile items to minimize damage during transit. Ensure that all necessary documentation, including invoices and customs forms, is complete and accurate to avoid customs complications. It’s also advisable to account for insurance options to protect your investment during shipping. -

Are there specific regulations or tariffs for importing 3D sculptures into my region?

Yes, importing 3D sculptures can be subject to various regulations and tariffs depending on your region. It’s crucial to research the specific import laws in your country, including any applicable duties, taxes, and restrictions related to artistic materials. Consulting with a customs broker can provide valuable insights into compliance requirements and help streamline the import process. -

How do I vet suppliers for 3D sculptures in international markets?

To vet suppliers, start by conducting thorough research online and checking their reputation through industry reviews and feedback from previous clients. Request references and case studies to assess their experience and reliability. Evaluate their communication responsiveness and willingness to accommodate your specific needs. Additionally, consider visiting trade shows or exhibitions to meet suppliers in person and view their work firsthand, which can help build trust and ensure a strong partnership.

Top 4 3D Sculpture Manufacturers & Suppliers List

1. Printables.com – 3D Printed Sculptures

ドメイン printables.com

はじめに Sculptures | Art & Design | 3D models | Printables.com | 3D Printed Sculptures | Busts of famous people, movie heroes statues, animal creatures, or miniatures | Trending models include: Zephyron – The Stormfang Wolf, Chibi Master Chief, Twisted Christmas Tree, Bonsai Tree – Minimalist, GIANT TRICERATOPS HEAD, Medusa Bust, Angry Unicorn, and more | Various designs available for different themes suc…

2. MakerWorld – 3D Printed Art Models

ドメイン makerworld.com

登録:2014年(11年)

はじめに 3D Printed Art Models available in various categories including 2D Art, Sculptures, and more. Models can be downloaded for printing and displayed in different environments. Featured models include How to Train Your Dragon Toothless, Mecha Pokemon Series Venusaur, Wolf Head Wall Relief, and Christmas-themed designs. The platform offers customizable options such as nozzle diameter and print time. Mo…

3. Pinterest – 3D Sculpture Ideas

ドメイン ピンタレスト・ドット・コム

登録:2009年(16年)

はじめに 900+ 3D / Sculpture ideas in 2025, including art lessons, sculpture teaching, and various related interests such as sculpture projects for high school and middle school, geometric paper sculpture, kinetic sculpture, cardboard art, bas relief art projects, nature-inspired sculpture projects, and more.

4. 3D Wasp – Delta WASP 3MT

ドメイン 3dwasp.com

登録:2017年(8年目)

はじめに 3D printed Art, 3D printed Sculptures, created with WASP’s 3D Printers. The Delta WASP 3MT is a large 3D printer dedicated to 3D sculpture. 3D printers can be applied in the restoration of Cultural Property and for creating 3D printed Statues for Cultural Heritage.

Strategic Sourcing Conclusion and Outlook for 3d sculpture

In the dynamic world of 3D sculpture, strategic sourcing emerges as a vital component for international B2B buyers. By leveraging a diverse range of suppliers and platforms, businesses can access unique, high-quality 3D models that resonate with various cultural contexts and consumer preferences. The ability to customize and rapidly prototype sculptures not only enhances product offerings but also fosters innovation and creativity, crucial for standing out in competitive markets.

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding local trends and preferences can lead to more effective sourcing strategies. Collaborating with local artists and designers can also open doors to culturally relevant designs that appeal to specific demographics, ultimately driving sales and customer loyalty.

As the 3D sculpture market continues to evolve, embracing new technologies and platforms will be essential. Companies should prioritize building relationships with reputable suppliers and investing in tools that streamline the design and production processes. By doing so, they can ensure they remain at the forefront of this exciting industry. The future of 3D sculpture is bright, and now is the time for B2B buyers to seize opportunities that align with their strategic goals.

重要な免責事項および利用規約

⚠️ 重要な免責事項

メーカー、技術仕様、市場分析に関する内容を含め、本ガイドラインで提供される情報は、情報提供と教育目的のみのものです。専門的な調達アドバイス、財務アドバイス、または法的アドバイスを提供するものではありません。

Illustrative image related to 3d sculpture

情報の正確性、最新性には万全を期していますが、誤謬、脱漏、古い情報については責任を負いかねます。市場の状況、企業の詳細、技術水準は変更される場合があります。

B2Bバイヤーは、独自の徹底的なデューデリジェンスを行う必要がある。 購入を決定する前に。これには、サプライヤーに直接問い合わせること、認定を確認すること、サンプルを請求すること、専門家に相談することなどが含まれる。本ガイドブックに記載された情報を信頼するリスクは、読者が負うものとします。