Ningbo Toprise Security Products Co., Ltd., as a company with 20 years of experience in exporting safety shoes, is dedicated to providing effective foot protection to customers worldwide. Our safety shoes are manufactured in strict accordance with CE standards for international markets. Here, we share how to choose the right upper material for our safety shoes.

The upper material is directly related to the shoe’s durability, comfort, and performance. A right choice of the material can provide uses with not only protection but also comfort. Below are the various types of commonly-used upper materials in safety footwear.

The upper material of the safety shoes on the market, there are mainly the following categories.

GENUINE LEATHER SAFETY SHOES:

- COWHIDE LEATHER SAFETY SHOES

- SPLIT LEATHER SAFETY SHOES

- SUEDE LEATHER SAFETY SHOES

ARTIFICIAL LEATHER SAFETY SHOES

- PU LEATHER SAFETY SHOES

- MICROFIBER SAFETY SHOES

- MESH FABRIC SAFETY SHOES

In order to help consumers buy the most suitable labor protection shoes, we will introduce different labor protection upper materials, as well as material characteristics, application scenarios, and price differences.

COWHIDE LEATHER SAFETY SHOES

The first layer of cow skin, that is, the rawhide of the cow, is cut into several layers by the skin-cutting machine, and the top layer connected to the cow skin is the first layer of cow skin. It has original skin features, including clear pores and skin texture.

Material characteristics: The first layer of cowhide is the surface skin of natural cowhide, with good permeability, softness, and toughness. It has a clear, natural texture, a soft feel, and is relatively durable. Due to the tight structure of the top layer, it has good waterproof and wear resistance.

Application scenario: It is suitable for working environments that require high comfort and durability, such as heavy industry and construction sites. The first layer of cowhide labor protection shoes is usually higher in price but provides a good wearing experience and protective effect.

SPLIT LEATHER SAFETY SHOES

The technical term for two-layer leather is microfiber synthetic leather, also known as two-layer transfer leather or split-layer transfer leather. Two layers of cowhide, also known as two layers of film transfer leather, are made by splitting thick skin with a leather machine, where the first layer is used to make full grain leather or shaved leather, and the second layer is made by a series of processes such as coating or film.

Material characteristics: Two layers of cowhide are the second layer under the first layer of cowhide; the texture is slightly harder than the first layer of cowhide; and the permeability and toughness are slightly poor. Two layers of cowhide surfaces are usually coated or treated (such as lamination or PU coating) to enhance their appearance and performance.

Application scenario: Due to the low cost, two-layer cowhide labor protection shoes are mostly used in workplaces with low comfort requirements, suitable for customers with tight budgets. Two-layer leather shoes in the medium intensity of the work environment performance is ok.

SUEDE LEATHER SAFETY SHOES

SUEDE LEATHER SAFETY SHOES

Suede, also known as turning fur, is the first layer of skin that is polished into a pile and then dyed in various colors.

Material characteristics: Suede is the inner layer of cowhide leather; after special treatment, the surface is fluff-like, with a soft texture and good permeability. Suede wear resistance is good, but the waterproof performance is relatively poor and easy to be damp.

Application scenario: Suede leather is often used in light industry and indoor working environments, suitable for dry working occasions. In addition, the appearance of suede leather labor protection shoes is fashionable but also has certain daily leisure attributes.

PU LEATHER SAFETY SHOES

PU faux leather is a type of artificial leather made mainly of polyurethane (PU) material. The production process of PU artificial leather involves applying a polyurethane coating to the substrate to form a material that has the appearance and texture of real leather. This material not only looks realistic and can imitate the texture and texture of natural leather, but also has a soft texture, a comfortable feel, and good touch and elasticity.

Material characteristics: low price, light texture, good wear resistance, good air permeability, easy to clean, etc.; its surface is smooth, not easy to absorb dust and stains; easy to clean and maintain; just use a wet cloth to wipe. The feel and elasticity may not fully achieve the effect of real leather and, in some cases, may not be as durable as real leather.

Application scenario: PU artificial leather labor protection shoes are suitable for wet or waterproof working environments, widely used in light industry, warehousing, and other places. Its low cost and relative durability make it the first choice for economical labor protection shoes.

MICROFIBRE SAFETY SHOES

Microfiber is made by chemical synthesis; its base material is mainly polyester amide fiber and polyamide fiber, through high-tech processing technology, to establish a small air gap between the fibers, forming a texture and feel similar to natural leather. At the same time, through needling and embossing and other processes, the surface of the shoe material can be more textured and beautiful.

Material characteristics: Wear resistance: shoes microfiber hardness is high, good wear resistance, not easy to wear and fade; Easy to clean: the surface of microfiber is smooth and fine, not easy to be contaminated with dust, easy to clean; Waterproof: microfiber has a certain waterproof performance, which can greatly extend the service life of shoes; Air permeability: Due to the influence of material characteristics and processing technology, shoe microfibers have certain air permeability. Poor toughness: the softness and hardness of the shoe microfiber are more consistent, so the toughness is poor, and it is not resistant to high temperatures and scratching; Strong imitation: the texture of the microfiber of the shoe is an imitation, and it cannot fully achieve the reality of natural leather or suede.

Application scenario: Microfiber leather labor protection shoes are often used in situations with high protection and comfort requirements, such as manufacturing and chemical industries. It is cost-effective and is ideal for some demanding operating environments.

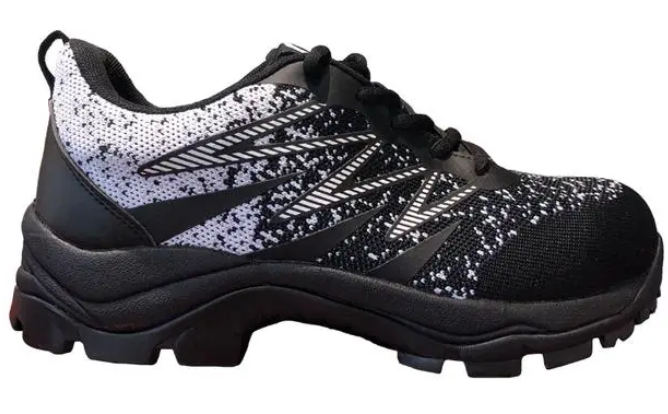

FLYKNIT BREATHABLE MESH SAFETY SHOES

Flying fabric is now a more popular upper processing technology. The concept is yarn fabric through computer programming design of the upper lines; this is the work of programming designers, and then together with the entire upper woven.

Material characteristics: With good permeability, it can keep the footsteps dry and is suitable for a summer and humid environment. Because of the good air permeability, so high comfort, can always keep dry, and beautiful environmental protection features. Compared with other labor protection shoes, the shortcomings mainly include stable formability, poor wear resistance, and water resistance.

Application scenario: Mesh shoes are often used in light industry, electronics factories, and other environments with high requirements for air permeability. Mesh shoes are suitable for high-temperature workplaces, but due to relatively weak wear resistance and protection, they are usually not suitable for heavy industry or high-risk occasions.

THE PRICE OF THE ABOVE SAFETY SHOES IS SORTED FROM HIGH TO LOW (the top material is not the same, the bottom and other configurations are the same).

THE PRICE OF THE ABOVE SAFETY SHOES IS SORTED FROM HIGH TO LOW

- COWHIDE LEATHER SAFETY SHOES

- SUEDE LEATHER SAFETY SHOES

- SPLIT LEATHER SAFETY SHOES

- MICROFIBER SAFETY SHOES

- FLYKNIT BREATHABLE MESH SAFETY SHOES

- MESH FABRIC SAFETY SHOES

It is believed that every consumer on the market has a detailed understanding of the surface material and material characteristics of the labor protection shoes, as well as the application scenario and the price. You can choose the most suitable for their own labor protection upper material.

If you have questions about labor protection shoes or purchase needs, feel free to contact us.