Workwear uniforms take a beating: abrasion, sweat, rain, concrete dust, industrial washing, and repeated drying. That is why workwear uniform customization has to be engineered, not just designed. The wrong logo method can crack after a few washes. The wrong placement can rub under a harness. And the wrong patch can peel when you need a professional look the most.

This guide explains how to customize uniforms with logos and name tags in a way that stays sharp, survives laundering, and does not compromise safety requirements.

Why Workwear Uniform Branding Fails on the Jobsite

Most durability problems come from a few predictable causes:

- The decoration method is not rated for industrial laundering (heat, chemicals, agitation).

- Logo placement sits on high-flex or high-abrasion zones (center front, belt line, cuffs).

- The method does not match the garment fabric (heavy embroidery on thin tees, thick patches on stretch panels).

- Heat transfer was applied with the wrong temperature, time, or pressure.

- Safety requirements were ignored (covering reflective tape, altering FR/AR performance, reducing hi-vis coverage).

Avoid these traps and your uniforms will look better longer, with fewer reorders and replacements.

The Most Durable Logo Methods for Workwear Uniforms

There is no one-size-fits-all solution. The right method depends on fabric type, job conditions, and how your uniforms are washed.

Embroidery for workwear uniforms

Best for:

- Softshell jackets, fleeces, heavyweight polos

- Hats and beanies

Why it lasts: Thread typically holds up well to repeated washing and abrasion.

Watch-outs:

- On lightweight tees, embroidery can pucker fabric and feel stiff.

- Dense embroidery on stretch fabrics can restrict movement.

- For hi-vis or FR/AR garments, confirm the supplier’s decoration rules before embroidering.

Εκτύπωση οθόνης for workwear uniforms

Best for:

- T-shirts, sweatshirts, hoodies

- Some work shirts depending on fabric and finish

Why it lasts: When ink is high quality and properly cured, prints can be very durable.

Watch-outs:

- Poor curing leads to cracking and peeling.

- Large solid blocks can reduce breathability and feel hot in summer.

Heat Transfer (Vinyl, DTF, or Transfer Labels) for workwear uniforms

Best for:

- Name tags and small chest logos

- Intricate designs and fast personalization

Why it lasts: High detail and consistent results across many garment types.

Watch-outs:

- Durability varies widely by transfer material and application quality.

- High-heat drying can shorten lifespan.

- Large transfers can trap heat and reduce stretch.

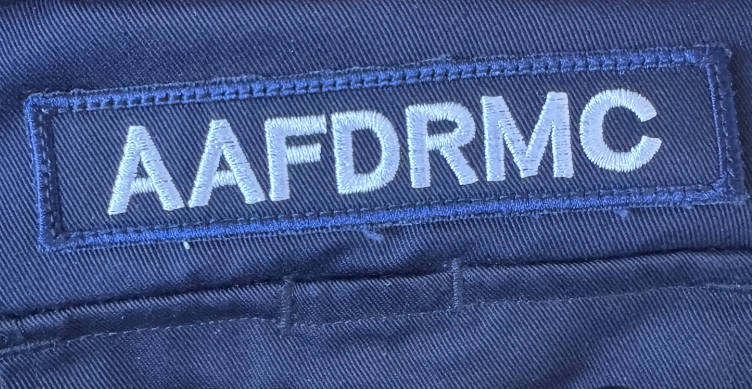

Woven or Embroidered Patches (Sewn-On or Heat-Applied) for workwear uniforms

Best for:

- Programs that need replaceable branding

- Role identifiers (foreman, safety, supervisor)

Why it lasts: Patches can be extremely tough and easy to standardize across sites.

Watch-outs:

- Heat-applied patches can lift at edges with heavy washing.

- Sewn patches can puncture waterproof membranes unless properly sealed.

Reflective Branding

Best for:

- Hi-vis programs and night work

- Roadside crews and warehouse operations

Why it lasts: Quality reflective films and inks maintain visibility when applied correctly.

Watch-outs:

- Never cover required reflective striping.

- Placement must preserve hi-vis coverage requirements.

Logo Placement Rules That Protect Durability and Comfort

Even the best decoration method fails if it sits in a high-flex, high-abrasion zone. Choose locations that stay visible and avoid constant rubbing from PPE and tool belts.

High-survival placement zones:

- Left chest (classic, low abrasion, visible under PPE)

- Upper sleeve (great for crew and role identification)

- Upper back/yoke (visible during work, avoids belt-line friction)

- Hats and beanies (excellent longevity and visibility)

High-failure zones (use carefully):

- Center front / stomach (flexing, harness rub, tool-belt abrasion)

- Lower back (belt friction, sweat, movement)

- Cuffs and pocket edges (snag and abrasion)

- High-stretch panels (transfers crack, embroidery distorts)

Name Tags That Stay On and Stay Readable

Name tags improve professionalism and communication, especially on multi-crew sites. The best option depends on turnover, laundering, and whether roles change.

Recommended name tag options:

- Heat-transfer name tags for clean, consistent personalization

- Embroidered name strips for heavier shirts and jackets

- Hook-and-loop (Velcro) panels when names or roles need to be swapped

Make name tags last longer:

- Keep tags small and light (less edge lift and stiffness).

- Avoid placing tags where harness straps cross.

- For hook-and-loop systems, use industrial-grade materials and reinforce stitching.

Do Not Break Safety Compliance While Customizing

If your uniform program includes hi-vis or FR/AR garments, customization needs extra controls.

Hi-Vis Considerations

- Do not place logos over reflective tape or required hi-vis panels.

- Ensure outerwear does not cover compliant hi-vis layers (or customize compliant outerwear).

- Confirm that customization does not reduce required coverage for your jobsite class.

FR/AR Considerations

- Customization can affect FR/AR performance depending on materials and method.

- Use only decoration approaches approved for FR/AR garments and follow supplier guidance.

Washing, Drying, and Practical Durability Testing

A logo that looks perfect on day one can fail by day twenty if you do not test under your real laundering conditions. Run a small pilot before large orders.

What to test before a bulk order:

- Wash cycles that match your temperature, detergent, and drying settings

- Edge lift on transfers and heat-applied patches

- Cracking on large print areas

- Colorfastness (garment and logo aging together looks more professional)

- Comfort under movement and sweat (stiff logos can irritate skin)

Vendor Questions That Protect Your Budget

Ask these questions upfront:

- Is this method rated for industrial laundering or home washing only?

- What is the expected lifespan in wash cycles for this decoration type?

- Do you have placement rules for hi-vis or FR/AR garments?

- How do you ensure reorders match (color, placement, and method consistency)?

Standardize Your Custom Workwear Uniform System

If you want consistent results across sites and reorders, standardize the basics:

- Approved logo sizes (chest, sleeve, back)

- Approved placement zones by garment type

- Approved decoration methods by fabric category

- Name tag format (first name vs full name, optional role)

- A simple spec sheet for each SKU so every reorder matches

ΣΥΧΝΈΣ ΕΡΩΤΉΣΕΙΣ

What is the most durable customization method for workwear uniform?

Embroidery and properly cured screen printing are often the most durable, but the best method depends on your fabric, job conditions, and laundering process.

Are heat transfers durable enough for workwear uniforms?

They can be, especially for small chest logos and name tags, if you choose industrial-rated transfers and apply them correctly.

Where should I place logos on hi-vis workwear uniforms?

Use zones that do not interfere with reflective tape or required hi-vis coverage, such as left chest, sleeves, or upper back/yoke, and follow site rules.

How do I prevent logos from peeling or cracking?

Choose the right method for the fabric, avoid high-flex zones, ensure proper curing/application, and test under real wash conditions before ordering in bulk.

Συμπέρασμα

Great workwear uniform customization balances durability, comfort, and compliance. Choose decoration methods that match your fabrics and laundering environment, place logos where they will not flex and abrade, and use name tags that improve communication without irritating workers. When customization is treated as a performance requirement instead of a design afterthought, uniforms stay professional longer, teams wear them consistently, and your brand shows up the right way on every site.