الشركة المصنعة لأحذية السلامة في الصين أحذية السلامة مصدر الإرشاد المصدر

أحذية السلامة الصين مصدر إرشادات الشركة المصنعة للأحذية: أحذية السلامة هي قطعة مهمة من معدات الحماية التي تحمي العمال من مختلف الإصابات المحتملة في مكان العمل.

نينغبو توبرايز هي شركة رائدة في مجال تصنيع أحذية السلامة في الصين وتتمتع بأكثر من 15 عامًا من الخبرة في هذا المجال. نحن ندعم الطلبات المخصصة لأحذية السلامة.

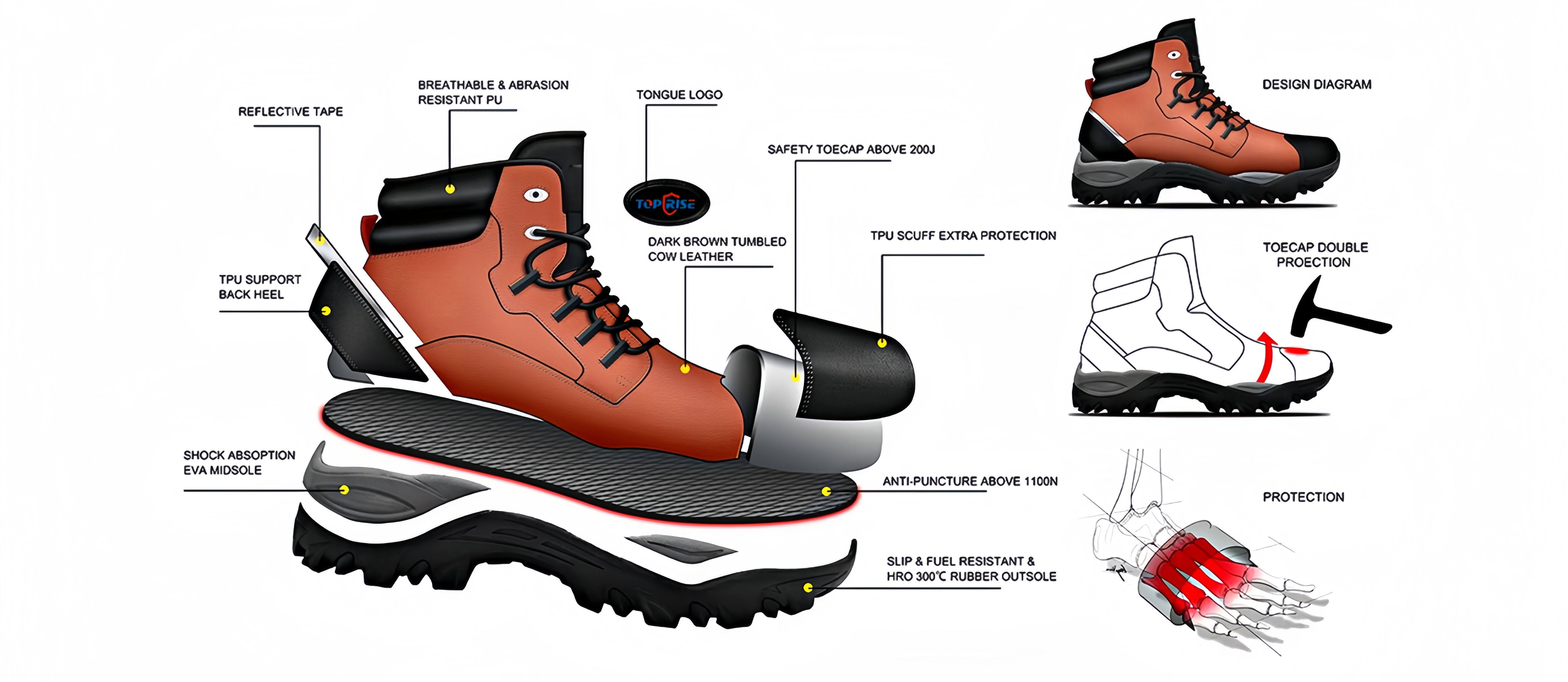

نينغبو توبريسه محترف الشركة المصنعة لأحذية السلامة مجهزة بمرافق إنتاج متطورة ونظام صارم لإدارة الجودة. تركز الشركة على تصميم أحذية السلامة عالية الجودة وإنتاجها وتصديرها، مع دعم كامل لتخصيص الأنماط والوظائف والأحجام لتلبية الاحتياجات المتنوعة لأماكن العمل. تشتمل المنتجات على ميزات مثل مضاد التحطيم، ومضاد للثقب، ومضاد للثقب، ومضاد للكهرباء الساكنة، وتستخدم على نطاق واسع في قطاعات البناء والصناعة والخدمات اللوجستية، مما يوفر للعملاء العالميين أحذية عمل آمنة ومريحة ومتينة.

القطع ← الخياطة العلوية ← الخياطة العلوية ← تثبيت العيون ← التثبيت ← التثبيت ← الفحص ← الاختبار ← الحقن ← خياطة اللحاء ← التعبئة→ المستودع→ التحميل

نوع الجلد | الخصائص | الاستخدام الموصى به |

جلد عالي الحبيبات | جلد عالي الجودة، ناعم ومتين؛ قابلية جيدة للتهوية والراحة؛ غالي الثمن | أحذية السلامة المتطورة للارتداء طويل الأمد في صناعات مثل البناء والتعدين |

جلد مقسوم | متين ومقاوم للتآكل؛ أقل تكلفة من الجلد المحبب الأعلى؛ أكثر صلابة وأقل مرونة من الجلد المحبب الأعلى | شائع في أحذية السلامة الصناعية العامة ذات القيمة الجيدة مقابل المال |

جلد صناعي | مصنوعة من خامات اصطناعية؛ خفيفة الوزن ومقاومة للماء؛ أقل قابلية للتهوية والراحة | مناسبة للبيئات ذات التكلفة المنخفضة مثل الصناعات الخفيفة والصناعات اللوجستية |

جلد الغنم | ناعم ومريح؛ قابلية جيدة للتهوية لتجربة ارتداء أفضل؛ أقل متانة من الجلود الأخرى | مثالية لبيئات العمل الخفيفة أو الارتداء طويل الأمد، ولكنها غير مناسبة للمهام الشاقة |

جلد الخنزير | جلد أكثر سُمكاً مع مقاومة أفضل للتآكل؛ قابلية جيدة للتهوية وراحة معتدلة | تُستخدم في أحذية السلامة في البيئات الصناعية المتطلبة، وغالباً ما تستخدم في المهام الشاقة |

جلد مطلي | مقاومة معززة للماء والبقع من خلال الطلاء؛ مناسب للبيئات الرطبة | مناسبة للبيئات ذات الرطوبة أو الملوثات، مثل صناعات التنظيف والصناعات الزراعية |

الجلود المعالجة خصيصاً (مثل الجلود المقاومة للحريق) | زيادة مقاومة الحرارة والحريق؛ يوفر حماية إضافية للبيئات ذات درجات الحرارة العالية | تستخدم في البيئات ذات درجات الحرارة العالية مثل اللحام وصناعات الطاقة والمهام المتخصصة |

جلد نابا | ملمس ناعم وأملس؛ راحة ممتازة وقابلية للتهوية؛ غالي الثمن | أحذية السلامة الراقية للارتداء طويل الأمد، مع التركيز على الراحة والمظهر في البيئات الراقية |

جلد الغزال | ملمس ناعم وسطح رقيق؛ يزيد من الراحة والمظهر الجميل؛ قابلية جيدة للتهوية | تُستخدم في أحذية السلامة الراقية للحصول على مظهر راقٍ ومريح، وهي مناسبة لبيئات العمل الخفيفة (مثل إعدادات المكاتب) |

الفئة | الوصف | الميزات الرئيسية |

S1 | أحذية السلامة الأساسية المناسبة للبيئات الداخلية | - حماية أصابع القدم (فولاذ/مركب)<br>- مضاد للكهرباء الساكنة<br>- نعل مقاوم للانزلاق |

S1P | مشابه ل S1، ولكن مع حماية إضافية من الثقب | - حماية أصابع القدم (فولاذ/مركب)<br>- مضاد للكهرباء الساكنة<br>- نعل مقاوم للانزلاق<br>- نعل مقاوم للثقب |

S2 | مناسبة للبيئات الخارجية، ومقاومة للماء | - حماية أصابع القدم (فولاذ/مركب)<br>- مضاد للكهرباء الساكنة<br>- نعل مقاوم للانزلاق<br>- جزء علوي مقاوم للماء |

S3 | حماية عالية، مناسبة للبيئات الرطبة والخطرة | - حماية أصابع القدم (فولاذ/مركب)<br>- مضاد للكهرباء الساكنة<br>- نعل مقاوم للانزلاق<br>- جزء علوي مقاوم للماء<br>- نعل مقاوم للثقب |

المواد | الخصائص | المزايا والعيوب | التطبيقات الشائعة |

إصبع القدم الحديدية والنعل الحديدي | مصنوع من ** مادة الحديد** لمقدمة القدم والنعل؛ حماية قوية | المزايا: قوة عالية، حماية جيدة؛ العيوب: ثقيلة، وغير مريحة في الارتداء، وعرضة للصدأ، وصعبة الصيانة | تُستخدم في البيئات الصناعية الثقيلة والإنشاءات والتعدين التي تتطلب حماية من الصدمات الشديدة |

إصبع القدم الفولاذي والنعل الفولاذي | مصنوعة من **الفولاذ** لمقدمة القدم والنعل؛ حماية قوية | المزايا: متينة، مقاومة جيدة للتآكل؛ العيوب: ثقيل، أقل راحة في الارتداء | يُستخدم في بيئات العمل عالية الكثافة مثل الإنشاءات والآلات الثقيلة واللحام |

كيفلار سول | **ألياف **كيفلر** مستخدمة في النعل، مما يوفر مقاومة عالية للتآكل ومقاومة للقطع والصدمات | المزايا: خفيفة الوزن، راحة عالية؛ العيوب: باهظة الثمن، تكلفة أعلى | تُستخدم في البيئات التي تحتاج إلى مقاومة للتآكل والقطع، مثل البناء والتعدين والآلات الثقيلة |

إصبع القدم البلاستيك | مصنوع من **البلاستيك** لإصبع القدم، خفيف الوزن وفعال من حيث التكلفة | المزايا: خفيفة الوزن وفعالة من حيث التكلفة؛ العيوب: حماية أقل، ليست قوية مثل الفولاذ أو الحديد | تُستخدم في البيئات الصناعية الخفيفة وبيئات العمل الداخلية حيث لا تكون هناك حاجة إلى حماية قوية من الصدمات |

إصبع قدم من سبائك الألومنيوم | مصنوعة من ** سبيكة ألومنيوم**؛ مقاومة قوية للصدمات وخفيفة الوزن ومقاومة للصدأ | المزايا: أخف من الفولاذ، حماية جيدة؛ العيوب: أضعف قليلاً من الفولاذ، أثقل من البلاستيك | تُستخدم في البيئات التي تتطلب الراحة والحماية، خاصةً في المواقف التي تحتاج إلى أحذية خفيفة الوزن |

إصبع القدم المركب | مصنوع من مواد **مركبة** (مثل الألياف الزجاجية وألياف الكربون) لمقدمة القدم؛ يوفر حماية جيدة | المزايا: خفيفة الوزن، غير موصلة للكهرباء، مقاومة جيدة للتآكل؛ العيوب: سعر أعلى، حماية أضعف قليلاً من الأصابع الفولاذية | تُستخدم في الإلكترونيات والطيران والصناعات الكيميائية، حيث يتطلب الأمر حماية خفيفة الوزن وغير قابلة للتآكل |

مادة النعل الخارجي | المزايا | العيوب | البيئات المناسبة |

نعل خارجي مطاطي | مقاومة جيدة للانزلاق؛ مقاومة قوية للتآكل؛ مقاومة للزيت والمواد الكيميائية | ثقيل؛ غير قابل للتنفس، قد يسبب عدم الراحة عند ارتدائه لفترة طويلة | مناسبة للبيئات التي تتطلب مقاومة الانزلاق والمتانة، مثل المطابخ والمصانع الكيميائية ومواقع البناء |

نعل خارجي من البولي يوريثين (بولي يوريثين) | خفيف الوزن؛ راحة جيدة؛ امتصاص الصدمات؛ مقاومة قوية للتآكل | متانة أقل مقارنةً بالمطاط؛ قد يفقد الأداء الأصلي مع مرور الوقت مع التآكل | مناسبة للبيئات التي تتطلب الراحة والوقوف أو المشي الطويل، مثل المستودعات والخدمات اللوجستية |

نعل خارجي EVA | خفيف الوزن للغاية؛ امتصاص جيد للصدمات؛ مريح؛ مقاوم للماء | مقاومة أقل للتآكل مقارنة بالمطاط والبولي يوريثان؛ قد تفقد مرونتها بمرور الوقت | مناسب للصناعات الخفيفة، والنقل، وبيئات المستودعات حيث الراحة وامتصاص الصدمات أمران مهمان |

نعل خارجي من البولي يوريثين الحراري (TPU) | مقاومة قوية للتآكل؛ مقاومة جيدة للضغط؛ مرونة، مما يحسن الراحة؛ مقاومة للزيوت والمواد الكيميائية | أعلى تكلفة؛ أكثر صلابة قليلاً، وأقل راحة مقارنة بالبولي يوريثان البولي يوريثان و EVA | مناسبة للبيئات ذات درجات الحرارة العالية والتآكل العالي، مثل الصناعات الكيميائية والبترولية وصناعات الصيانة الميكانيكية |

نعل خارجي مركب من المطاط/البولي يوريثان | متين؛ راحة جيدة ومقاومة جيدة للانزلاق؛ مقاومة جيدة لدرجات الحرارة | ثقيلة نسبياً؛ مناسبة للبيئات عالية الكثافة | مناسب للصناعات الثقيلة والبناء والتعدين |

حدد الغرض من الحذاء (داخلي/خارجي)، وبيئة العمل (رطب، زيتي، التعرض للمواد الكيميائية، إلخ)، وميزات السلامة (الحماية من الصدمات، مقاومة الثقب، مقاومة الانزلاق، إلخ).

اختر ما يناسبك من الفولاذ أو المواد المركبة أو الألومنيوم لتوفير الحماية والراحة المثلى.

اختر مواد النعل الخارجي المناسبة مثل المطاط أو البولي يوريثان أو البولي يوريثان البوليسترين لضمان مقاومة الانزلاق ومقاومة التآكل بشكل جيد.

حدد اللون والنمط والشعار والعلامة التجارية للحصول على مظهر مخصص.

اختر ميزات مثل النعال الداخلية الممتصة للصدمات أو البطانات المسامية أو الوظائف المقاومة للماء لتعزيز الراحة.

توفير قياسات دقيقة لمقاس الحذاء لضمان الحصول على المقاس المثالي للراحة والدعم.

أضف وظائف خاصة مثل مقاومة الكهرباء الساكنة أو المقاومة الكيميائية أو العزل الكهربائي بناءً على احتياجات بيئة العمل.

راجع العينة للتأكد من ملاءمتها وتصميمها قبل البدء في الإنتاج بالجملة ووضع اللمسات الأخيرة على جدول التسليم.

يتمتع مصنع نينغبو توبرايز لأحذية السلامة في نينغبو بسنوات عديدة من الخبرة في الإنتاج، مع التركيز على تزويد العملاء في جميع أنحاء العالم بمعايير عالية وأحذية عمل عالية الجودة.

احصل على سعر تنافسي لأحذية السلامة

يتم إنتاج كل زوج من أحذية السلامة التي تنتجها شركة NINGBO TOPRISE وفقًا للمعايير الدولية CE لضمان أن كل زوج من الأحذية له وظائف رئيسية مثل عدم الانزلاق، ومقاومة الثقب، والرأس الفولاذي، والقاع الفولاذي، وذلك لضمان سلامة العمال إلى أقصى حد.

لدينا شهادة CE قياسية مختلفة وشهادة ANSI للحفاظ على جودة منتجاتنا.

يمكن لمصممنا الخاص أن يقدم لك خدمات تصميم مخصصة لأسلوبك في تصميم أحذية السلامة الخاصة بك، كما أن تصنيع المعدات الأصلية مقبول.

نحن موردون مباشرون لأحذية السلامة في الصين، والتي يمكن أن نقدم لك أسعارًا تنافسية لأحذية السلامة.

بالنسبة لطلب تصنيع المعدات الأصلية الخاص بك، يمكننا تسليمه خلال 30 يوم عمل، وبالنسبة لإنتاج العينات، خلال 7 أيام.

نتحقق من الجودة أثناء الإنتاج للتأكد من اجتياز الجودة، ثم نقوم بالتعبئة.

تقديم خدمة فعالة بعد البيع بعد البيع.

نينغبو توبرايز هي شركة موثوقة أحذية السلامة المورد والشركة المصنعة في الصين. لقد قمنا بتصدير العديد من أحذية السلامة إلى أكثر من 30 دولة، بما في ذلك الولايات المتحدة وألمانيا والمملكة المتحدة واليونان وفرنسا والنمسا والشرق الأوسط وأفريقيا.

خدمات تصنيع أحذية السلامة OEM هي ما نقوم به بشكل أساسي. يمكن تخصيص الأحذية بشعارك. يمكننا توفير معايير مختلفة من أحذية السلامة. عادة ما يكون موك لدينا 500 زوج لكل نمط.

اجتازت معظم أحذية السلامة لدينا معايير الجودة ANSI و CE.

يسعدنا إقامة علاقات تجارية مع العملاء في جميع أنحاء العالم ومساعدتهم على تحقيق فوائد أكبر من خلال منتجات وخدمات عالية الجودة.

جودة مذهلة؛ كان وقت الشحن حوالي 45-50 يومًا، وهي المدة التي قيل لي أنها ستستغرقها بالضبط؛ وقد جاءت جميعها معبأة بشكل فردي.

جودة مذهلة؛ كان وقت الشحن حوالي 45-50 يومًا، وهي المدة التي قيل لي أنها ستستغرقها بالضبط؛ وقد جاءت جميعها معبأة بشكل فردي.

كان من السهل جدًا التعامل مع مندوب المبيعات وكان غنيًا بالمعلومات عن المنتجات المعروضة. تمت معالجة الطلب وشحنه بسرعة. كان التغليف جيداً جداً، ووصلت جميع المنتجات في حالة ممتازة دون أي تلف. شكرًا لك!

كان من السهل جدًا التعامل مع مندوب المبيعات وكان غنيًا بالمعلومات عن المنتجات المعروضة. تمت معالجة الطلب وشحنه بسرعة. كان التغليف جيداً جداً، ووصلت جميع المنتجات في حالة ممتازة دون أي تلف. شكرًا لك!

قام البائع بإنتاج المنتجات وتسليمها في الوقت المناسب مع خدمة عملاء ممتازة. كانت المنتجات المطلوبة في حالة ممتازة وتناسب احتياجات شركتنا، ونتطلع إلى التواصل مع البائع في الطلبات المستقبلية.

قام البائع بإنتاج المنتجات وتسليمها في الوقت المناسب مع خدمة عملاء ممتازة. كانت المنتجات المطلوبة في حالة ممتازة وتناسب احتياجات شركتنا، ونتطلع إلى التواصل مع البائع في الطلبات المستقبلية.

الجودة جيدة جداً، والسعر أرخص أيضاً من الموردين الآخرين.

الجودة جيدة جداً، والسعر أرخص أيضاً من الموردين الآخرين.

أحذية السلامة هي أحذية مصممة خصيصاً لحماية القدمين من الإصابات في بيئات العمل الخطرة. تُستخدم عادةً في الإنشاءات والمصانع والمستودعات وأماكن العمل الأخرى حيث توجد مخاطر مثل سقوط الأجسام أو المواد الحادة أو الأسطح الزلقة. عادةً ما تتميز أحذية السلامة بمكونات واقية مثل الأصابع الفولاذية أو المركبة والنعال المقاومة للثقب والنعال الخارجية المقاومة للانزلاق، مع توفير الراحة لساعات طويلة من الارتداء.

يمكن تصنيف مواد أحذية السلامة إلى ثلاثة أجزاء رئيسية: الجزء العلوي والنعل والمكونات الواقية. تحدد المواد المختلفة الراحة والأداء الوقائي والاستخدامات المناسبة للأحذية.

جلد: متينة وقابلة للتنفس ومريحة، ومناسبة لبيئات العمل عالية الكثافة مثل البناء والمصانع.

جلد صناعي (PU، PVC): خفيف الوزن، مقاوم للماء، مقاوم للماء، مقاوم للزيوت، وسهل التنظيف، يستخدم عادةً في الأعمال الصناعية واللوجستية.

نسيج/قماش شبكي: عالية التهوية ومثالية لبيئات العمل الداخلية أو بيئات العمل ذات درجات الحرارة العالية.

المطاط: مقاومة للانزلاق، ومقاومة للتآكل، ومقاومة للمواد الكيميائية، ومناسبة للبيئات الخارجية أو الرطبة.

البولي يوريثين (PU): خفيف الوزن وممتص للصدمات ومقاوم للصدمات، ومناسب لساعات طويلة من العمل واقفًا.

مطاط لدن بالحرارة (TPR): مقاومة للاهتراء، ومقاومة للانزلاق، ومقاومة للحرارة، وغالبًا ما تستخدم في أحذية السلامة الصناعية.

إصبع القدم الفولاذي: يحمي من السحق والصدمات؛ الحماية الأساسية لأحذية السلامة التقليدية.

إصبع القدم المركب: غير معدنية وخفيفة الوزن ومقاومة للصدمات؛ مناسبة للمناطق التي لا تحتاج إلى معدن.

نعل أوسط مقاوم للثقب (فولاذ أو كيفلر): يحمي النعل من المسامير والأشياء الحادة، مما يضمن سلامة القدم.

المواد المضادة للكهرباء الساكنة (ESD): مناسب لتصنيع الإلكترونيات والبيئات الأخرى المضادة للكهرباء الساكنة.

مواد مقاومة للحرارة أو مواد مقاومة للمواد الكيميائية: مناسبة لأماكن العمل المتخصصة، مثل المصانع الكيميائية أو صناعات الصهر.

المعايير الدولية لـ أحذية السلامة تحديد الحد الأدنى من متطلبات الحماية وطرق الاختبار لضمان سلامة العمال. وتشمل المعايير المعترف بها عادة ما يلي:

EN ISO 20345 (أوروبا): يحدد متطلبات أحذية السلامة، بما في ذلك حماية الأصابع، ومقاومة الانزلاق، والخصائص المضادة للكهرباء الساكنة.

أستم F2413 (الولايات المتحدة الأمريكية): يغطي مقاومة الصدمات والضغط، والحماية من الثقب، والحماية من المخاطر الكهربائية.

CSA Z195 (كندا): يحدد معايير الأداء للأحذية الواقية، بما في ذلك مقاومة النعل للثقب، وحماية أصابع القدم والمتانة.

تساعد هذه المعايير أصحاب العمل والمصنعين على ضمان أن أحذية السلامة توفر حماية موثوقة في مختلف بيئات العمل الخطرة.

أحذية السلامة ضرورية لحماية العمال من إصابات الأقدام في البيئات الخطرة. فهي تحمي من الأجسام الثقيلة المتساقطة والأدوات الحادة والأرضيات الزلقة والمخاطر الكهربائية. تجمع أحذية السلامة الحديثة بين الحماية والراحة، حيث تتميز بأصابع فولاذية أو مركبة، ونعال مقاومة للثقب، ونعال خارجية مقاومة للانزلاق لضمان السلامة دون الحد من الحركة.

يؤدي اختيار أحذية السلامة المناسبة لأماكن عمل معينة - مثل مواقع البناء أو المصانع أو المستودعات - إلى تقليل الحوادث وتعزيز الإنتاجية. وبالإضافة إلى السلامة، فإن أحذية السلامة المصممة بشكل جيد تحسن المظهر المهني وتعزز الامتثال لممارسات السلامة في مكان العمل. لا يعد الاستثمار في أحذية السلامة عالية الجودة إجراءً وقائيًا فحسب، بل هو أيضًا وسيلة لدعم رفاهية الموظفين وكفاءتهم.

بالنسبة لأحذية السلامة لدينا، نحتاج إلى موك 500 زوج. يتم طلب موك حسب الطلب المخصص وفقًا لمتطلباتك.

أحذية السلامة يتم تصنيفها إلى درجات مختلفة بناءً على معيار EN ISO 20345. توفر SB الحماية الأساسية من الصدمات للأماكن الصناعية العامة. توفر S1 و S1P ميزات إضافية مثل الخصائص المضادة للكهرباء الساكنة والكعب الممتص للطاقة ومقاومة الثقب، مما يجعلها مناسبة للبيئات الداخلية أو المستودعات. أما S2 و S3 فيتميزان بمقاومة الماء والحماية من الانزلاق، مما يجعلهما مثاليان للأماكن الخارجية أو الرطبة. أما S4 و S5، المصنوعان من المطاط الكامل أو البولي يوريثين، فيوفران أقصى قدر من الحماية ضد الصدمات والثقوب والانزلاق والاستاتيكية، وهما مناسبان للبيئات عالية الخطورة أو البيئات المتخصصة مثل المصانع الكيميائية أو الزراعة أو مواقع البناء.

نحن الشركة المصنعة لأحذية السلامة منذ عام 2009.

لطلب أحذية السلامة يعتمد وقت التسليم على الكمية. الأسرع أن يكون في غضون 20 يومًا، وسيستغرق الطلب المخصص أكثر من 35 يومًا.

نعم ، لدينا أكثر من 15 عامًا من الخبرة في تصنيع المعدات الأصلية. يمكننا إضافة شعارك الخاص على أحذية السلامة وإضافة شعارك الخاص على العبوة للكمية التي تحتاجها لتلبية طلب موك الخاص بنا.

يمكننا إنتاج عينة لك للتحقق من الجودة والأسلوب ولكننا نفرض تكلفة العينة وفقًا لذلك. ضع الطلب، وسنقوم بإرجاع رسوم العينة لك.

يمكننا أن نقدم لك خدمة الشحن من الباب إلى الباب بما في ذلك الشحن إلى جانبك عن طريق البريد السريع أو عن طريق الجو أو البحر.

يمكنك إرسال الاستفسار إلينا عبر البريد الإلكتروني sales@toprisesafety.com أو الاتصال بنا مباشرة على 0086-15824203641.

بالطبع، يمكننا المساعدة في شحن طلبك مع الموردين الآخرين إذا كنت بحاجة إلى ذلك. كما نقدم لك أيضًا خدمة الشراء من محطة واحدة منا.

نعم. نحن ندعمك في تخصيص حزمة أحذية السلامة.

أحذية السلامة الصين مصدر إرشادات الشركة المصنعة للأحذية: أحذية السلامة هي قطعة مهمة من معدات الحماية التي تحمي العمال من مختلف الإصابات المحتملة في مكان العمل.

يعد اختيار حذاء العمل المناسب المقاوم للانزلاق أمراً بالغ الأهمية للسلامة في البيئات الزلقة. توصي Toprisesafety بالأحذية ذات النعل الخارجي المناسب للأسطح الرطبة أو الزيتية أو غير المستوية.

يتطلب العمل في البيئات ذات الأسطح الزلقة أحذية مناسبة. تساعد الأحذية المقاومة للانزلاق على تحسين السلامة والإنتاجية. في صناعات مثل الإنشاءات والرعاية الصحية وخدمات الطعام، فإن اختيار

المؤلف: شركة نينغبو توبرايز للمنتجات الأمنية المحدودة Ningbo Toprise Security Products Co.,Ltd Facebook Linkedin Youtube نينغبو توبرايز، كشركة مصنعة محترفة لأحذية العمل منذ عام 2019، مكرسة لتوفير حماية فعالة للقدم

تكرس شركة نينغبو توبرايز للمنتجات الأمنية المحدودة (Ningbo Toprise Security Products Co., Ltd.)، كشركة تتمتع بخبرة 20 عامًا في تصدير أحذية السلامة، جهودها لتوفير حماية فعالة للقدمين

تكرس شركة نينغبو توبرايز للمنتجات الأمنية المحدودة (Ningbo Toprise Security Products Co., Ltd.)، كشركة تتمتع بخبرة 20 عامًا في تصدير أحذية السلامة، جهودها لتوفير حماية فعالة للقدمين

RM602 Yun Hui Zhong Xin, NO.299 Tong Ji Road, Qian Jiang Jiang Jie Dao, Jiang Bei, Ningbo, الصين

0086-574-87126687

0086-15824203641

sales@toprisesafety.com

تعمل شركة نينغبو توبرايز للمنتجات الأمنية المحدودة بشكل رئيسي في خطوط واسعة من معدات الوقاية الشخصية ومنتجات السلامة على الطرق والسلع الخارجية ومنتجات FRP التي تلعب دورًا مزدوجًا كشركة مصنعة وتاجر، بهدف تقديم المنتجات الأكثر فعالية من حيث التكلفة لكل عميل والمساعدة بشكل كبير في تقليل مشاكل كل عميل من خلال تقديم التسوق الشامل لأكثر من 15 عامًا.

هل لديك سؤال؟ تواصل معنا على الفور باستخدام النموذج أدناه.

سيقوم فريق دعم العملاء لدينا بالرد عليك قريباً.